Vibrating diaphragm-type zero-frequency and high-tone-quality loudspeaker

A zero-frequency, loudspeaker technology, applied in the field of audio equipment, can solve problems such as difficult to guarantee sound quality and poor low-frequency response of loudspeakers, and achieve the effect of simple structure, low distortion, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

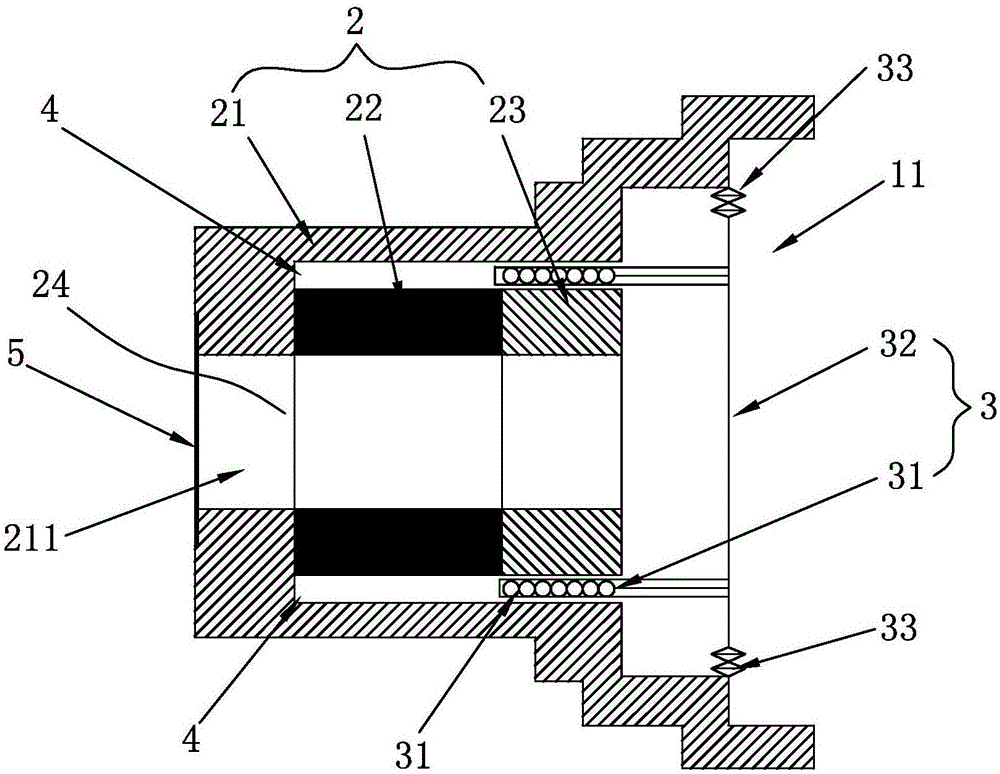

[0026] refer to figure 1 The diaphragm-type zero-frequency high-quality sound speaker is composed of a magnetic field part 2 and a diaphragm moving part 3. The magnetic field part 2 is a hollow body composed of an annular iron block 21, a magnetic ring 22 and a washer 23. The annular iron block 21 described above is a barrel-shaped iron block. A through hole 211 is provided in the middle of the bottom of the annular iron block 21. The magnetic ring 22 and the washer 23 are arranged in sequence and fixed on the inner bottom of the annular iron block 21. The magnetic ring 21 There is a gap 4 between the outer wall of the ring 22 and Washer 23 and the inner wall of the annular iron block 21; the diaphragm moving part 3 is composed of a voice coil 31, a diaphragm 32 and an elastic wave 33, and the voice coil 31 is wound The coil in the gap 4, the diaphragm 32 is fixedly installed at the opening 11 of the annular iron block 21, and is a film that is tightly attached to the voice co...

Embodiment 2

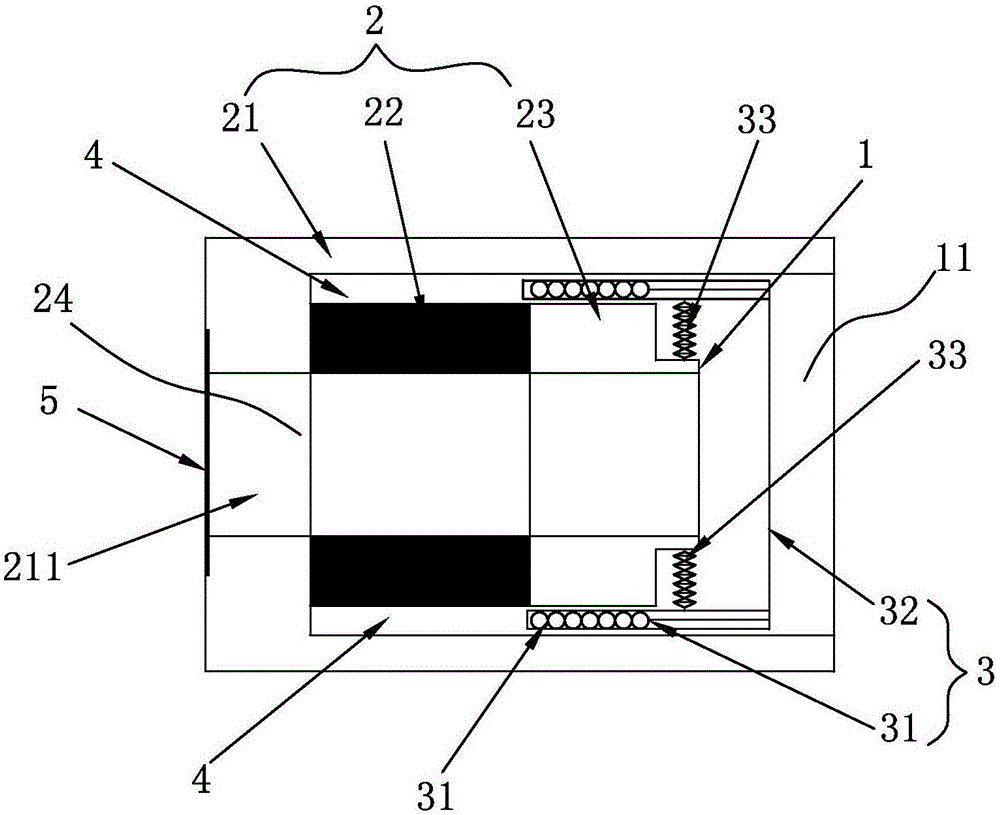

[0032] refer to figure 2 As shown, the technical characteristics of the present invention are: the inner side of the washer 23 is provided with an annular raised portion 1, the inner side of the elastic wave 33 is fixed with the annular raised portion 1, and the outer side is fixed on the voice coil 31; The diaphragm 32 is fixed on the voice coil 31 through the outer edge. All the other are the same as the above embodiment.

[0033] According to the above technical characteristics, the technical characteristics and structure of the present invention (hereinafter referred to as "diaphragm type loudspeaker") and the existing "paper cone type loudspeaker" are as follows:

[0034] 1. The difference in performance and characteristics between the two is:

[0035] 1. "Paper cone type speaker" has a paper cone, and "diaphragm type speaker" has a diaphragm.

[0036] 2. "Paper cone type speaker" relies on the paper cone to convert the movement of the voice coil into sound, and "diap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com