Streamline-based automatic dispensing tracking method and device

An automatic tracking and dispensing device technology, applied to the device and coating of the surface coating liquid, can solve the problems of procrastination in the production process, fixture wear, and processing quality that cannot meet the requirements, so as to improve the degree of automation and efficiency. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

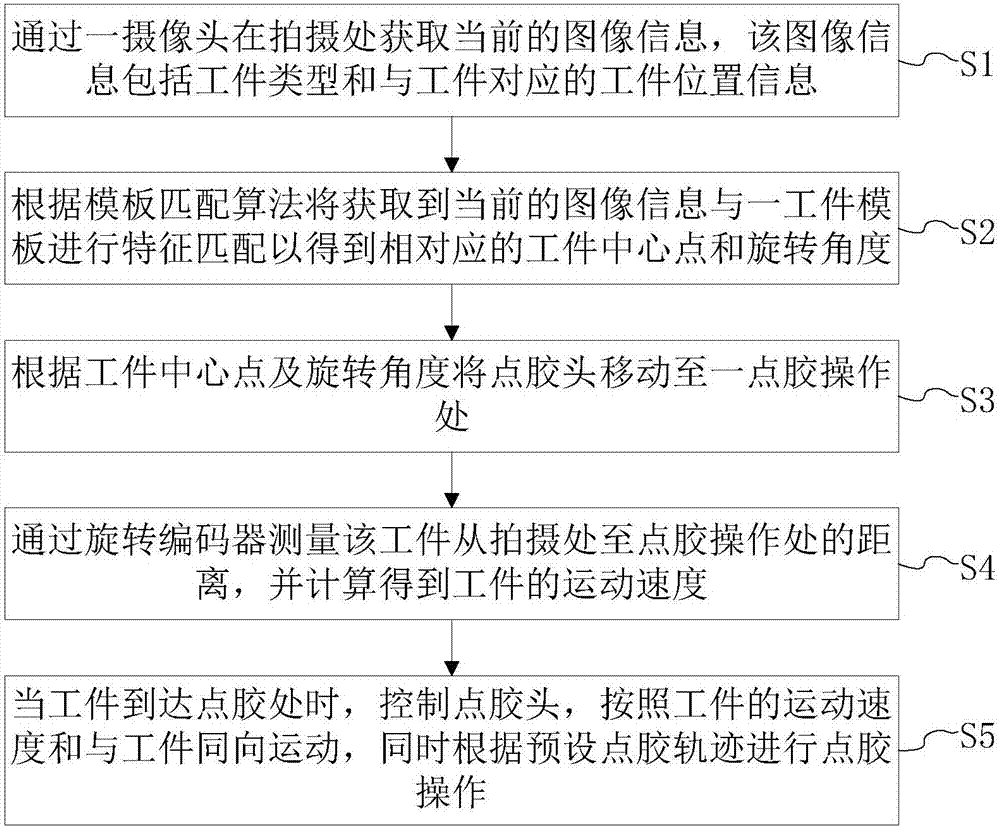

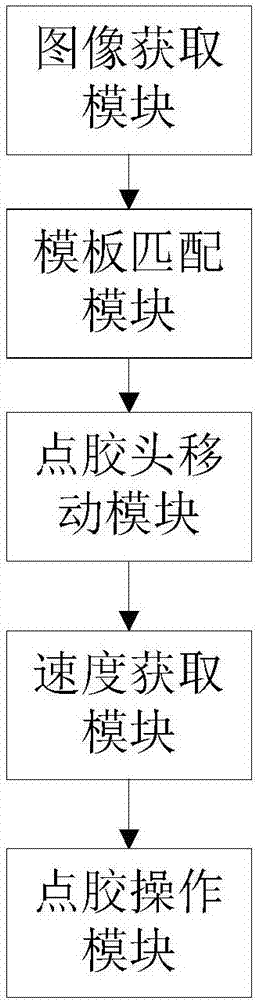

[0036] Such as figure 1 As shown, the invention provides a kind of automatic tracking dispensing method based on assembly line and comprises the following steps:

[0037] S1: Obtain the current image information at the shooting place through a camera, the image information includes the workpiece type and the workpiece position information corresponding to the workpiece; step S1 specifically includes the following sub-steps:

[0038] S11: Obtain current image information at the shooting place through a camera;

[0039] S110: Correct the image information according to a distortion parameter obtained through an image calibration method; the image calibration method adopted is the Zhang Zhengyou calibration method; it must be ensured that the image captured by the camera can restore objects in the space , the ideal situation is that there is a simple line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com