HCU and clutch work mode switching control method

A technology of working mode and control method, applied in hybrid vehicles, motor vehicles, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

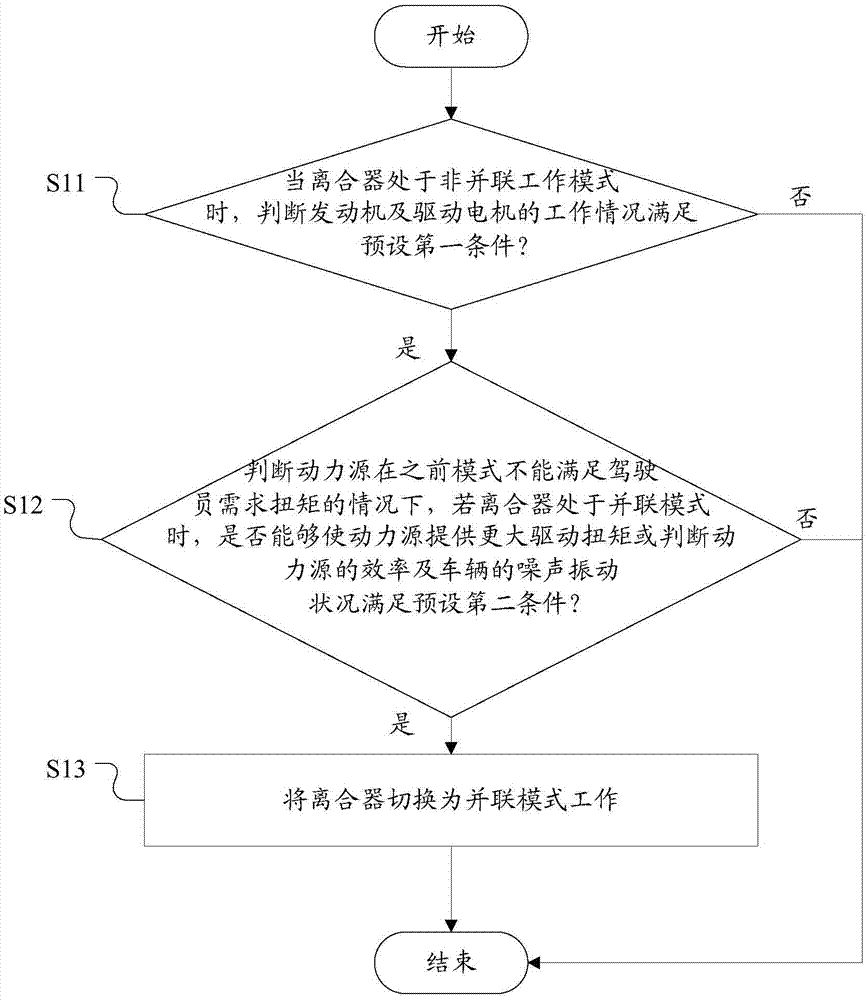

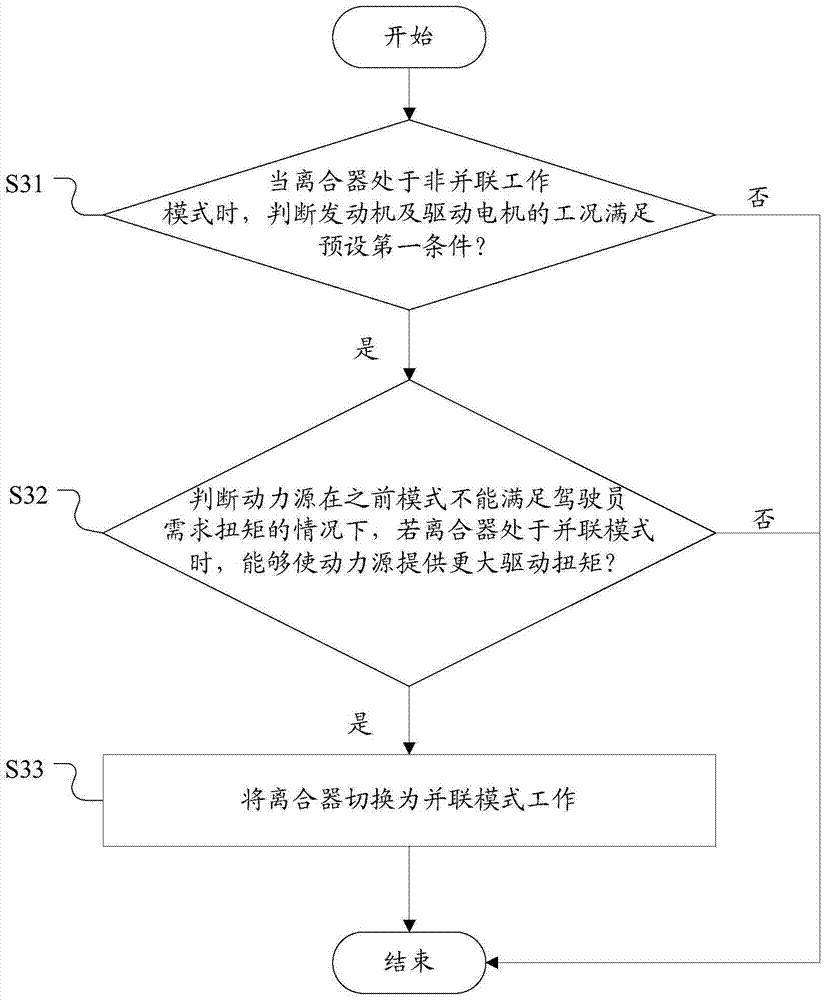

[0176] The clutch has three working modes: pure electric drive mode, series mode and parallel mode. At present, the parallel operation mode switching method of the clutch is to control the clutch to enter the parallel operation mode only when a large vehicle driving demand torque is required for rapid acceleration or climbing, or the required vehicle driving demand torque increases rapidly. However, the above-mentioned scheme of switching the working mode of the clutch is likely to cause insufficient power of the vehicle, affect driving safety, and also cause resonance and high noise.

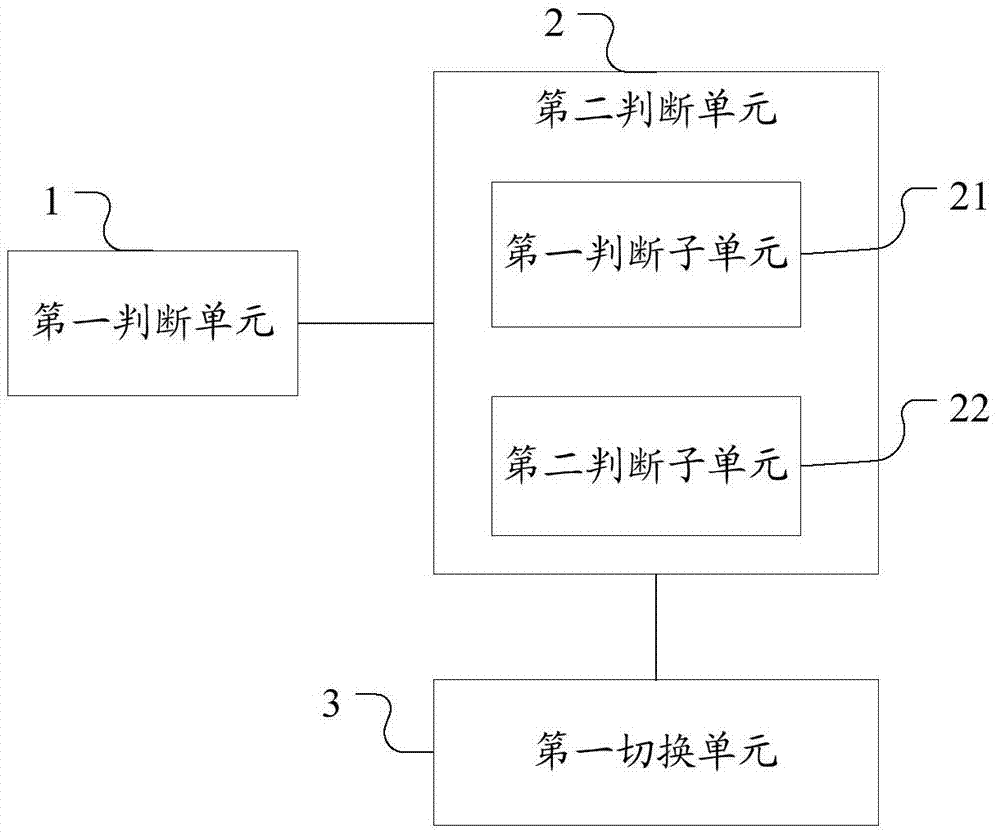

[0177] In order to solve the above problems, the embodiment of the present invention provides a control method for HCU and clutch working mode switching. If the clutch is currently in the non-parallel working mode, when it is determined that the clutch is in the parallel mode, the power source can provide a larger driving torque, or in When the efficiency of the power source and the noise and v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com