Air cooled condenser unit with optimized operation

An air-cooled condenser and operation optimization technology, which is applied to steam/steam condensers, lighting and heating equipment, etc., can solve problems such as lag adjustment, fluctuations in operating parameters, and large power consumption of fans, so as to achieve early response and avoid lag performance and improve control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

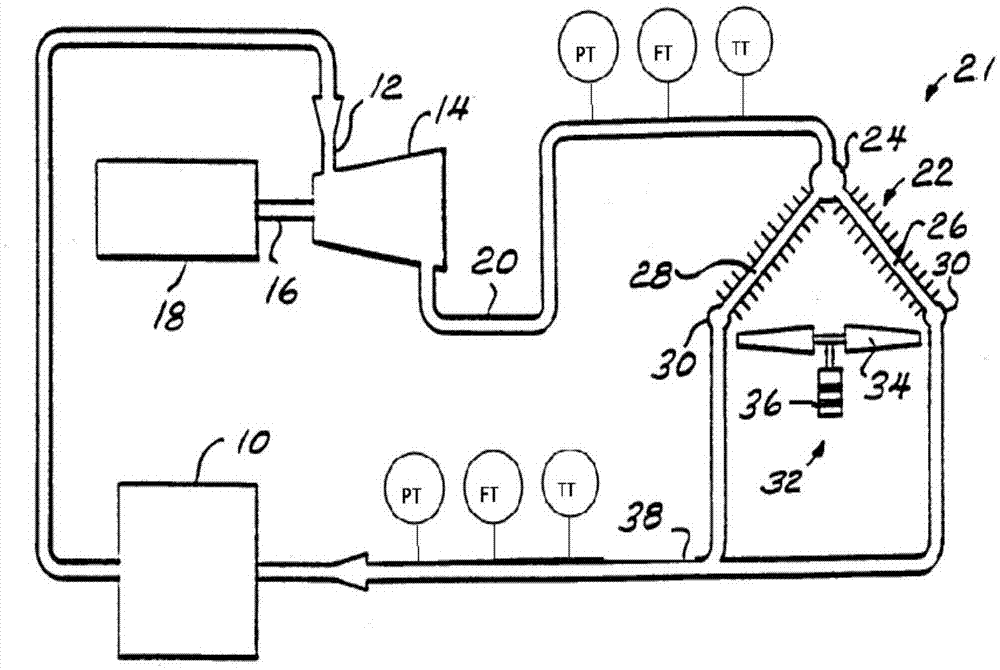

[0025] figure 1 An exemplary steam-water system diagram is shown, which includes a boiler 10 , a steam turbine 14 , a generator 18 and an air-cooled condenser unit 21 . The boiler burns to heat water to form water vapor. The water vapor flows into the steam turbine 14 through the pipeline 12. The hot water vapor expands in the steam turbine to drive the turbine to rotate. The steam turbine drives the generator 18 to generate electricity through the output shaft 16. The steam discharged from the steam turbine 14 enters the direct air-cooled condenser unit 21 through the pipeline 20 . The air-cooled condenser unit 21 mainly includes an air-cooled condenser 22 . The air-cooled condenser 22 includes a heat exchange tube bundle 26 and a fan device 32 . The heat exchange tube bundle 26 receives the turbine exhaust steam from the pipeline 20, and collects all the exhaust steam in the common upper header 24, and the tubes forming the heat exchange tube bundle are respectively arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com