Air tightness checking device and method by liquid nitrogen pressurization and gasification

A technology of air tightness inspection and liquid nitrogen, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problems of gas cylinder consumption and long charging time, and achieve high safety and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

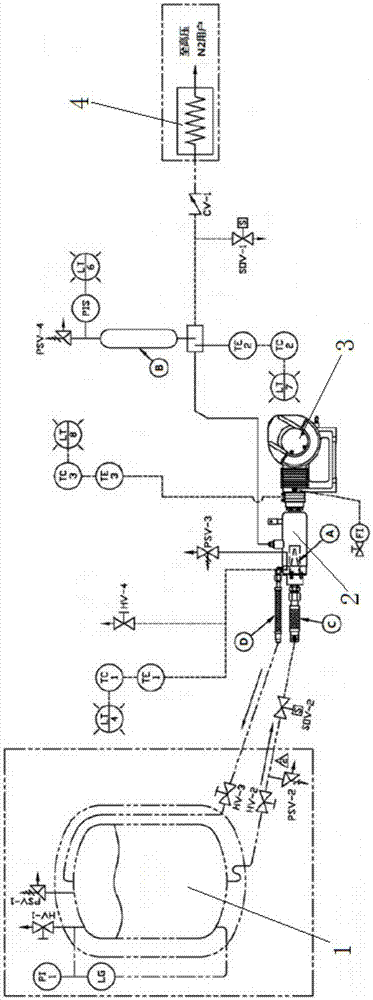

[0042] The equipment of the present invention comprises a liquid nitrogen tank 1, a liquid nitrogen booster pump 2, a vaporizer 4, valves, pipelines, indicators and safety valves.

[0043] Install the liquid nitrogen outlet valve HV-2 at the bottom of the liquid nitrogen tank 1, and connect the pump inlet elbow C, and set the supply line safety valve PSV-2 and solenoid valve SOV-2 on the connecting pipe in sequence;

[0044] The pressure relief valve HV-1 and the storage tank safety valve PSV-1 are installed on the top of the liquid nitrogen tank 1. These two valves are used to ensure that the pressure in the liquid nitrogen tank 1 is in a stable state; when the pressure in the liquid nitrogen tank 1 is too high When , the storage tank safety valve PSV-1 automatically takes off to release the pressure.

[0045] Install temperature element TE-1, low temperature controller TC-1 and pump start-up indication LT-4 at pump return elbow D;

[0046] Install a pipe at one end of the ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com