High-transmittance metal grid flexible conductive film and preparation process thereof

A metal grid, flexible conductive technology, applied in the direction of cable/conductor manufacturing, conductive layer on the insulating carrier, circuit, etc., can solve the problems that are not very complete, difficult to balance conductivity and light transmittance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

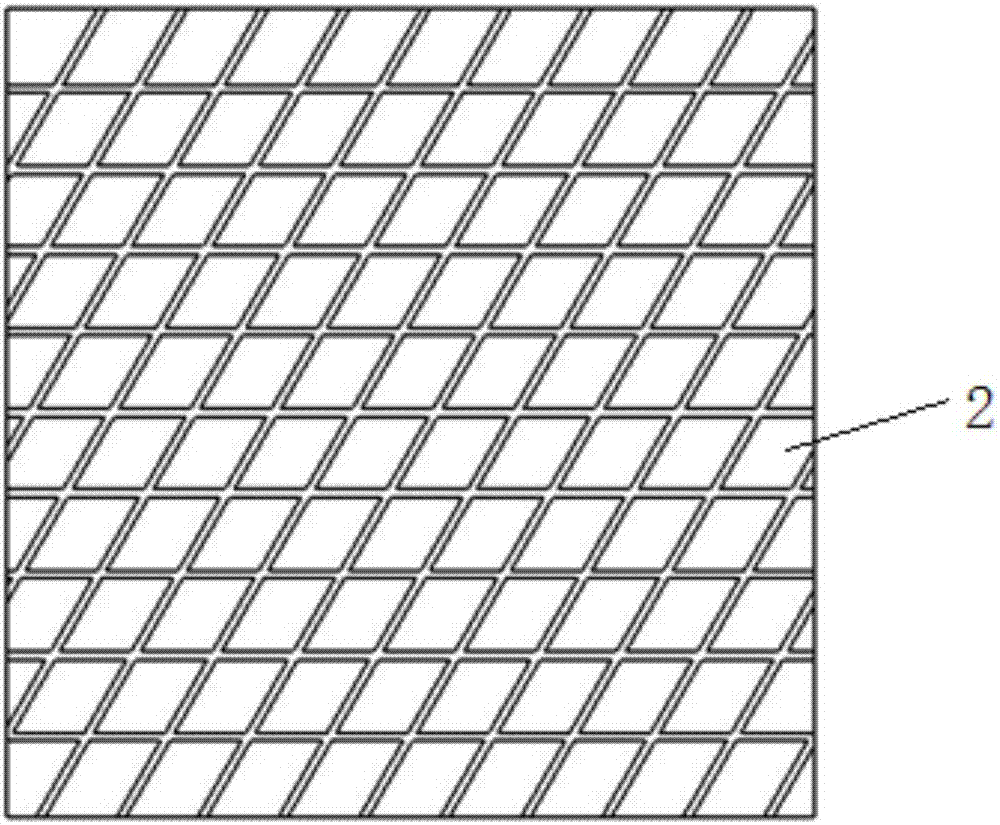

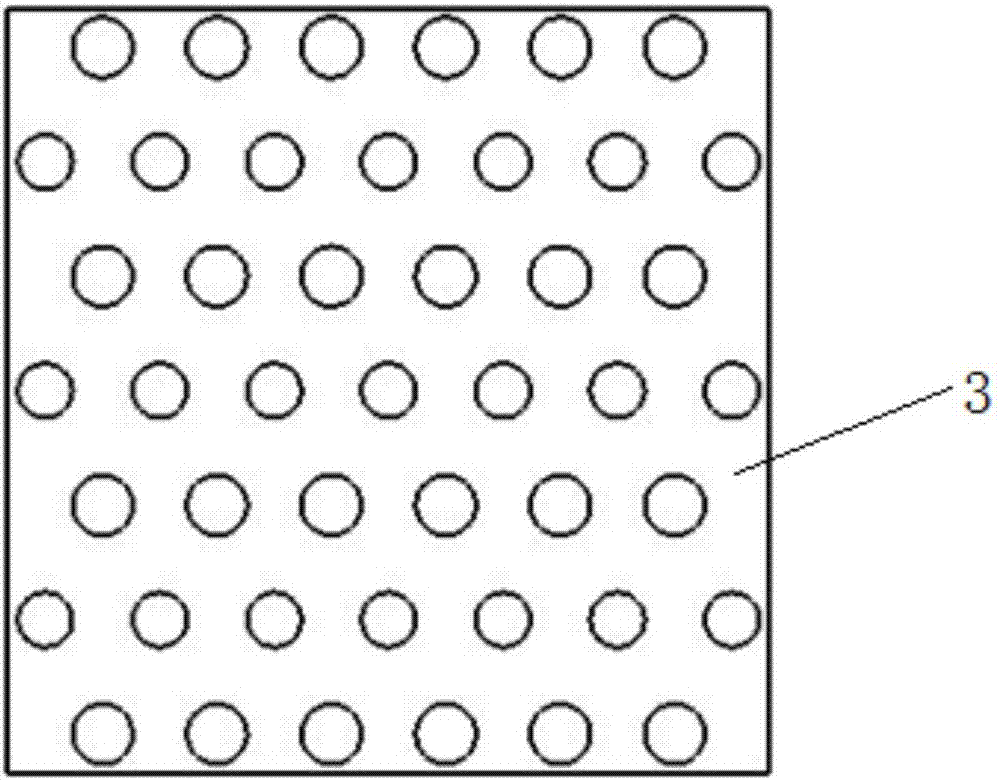

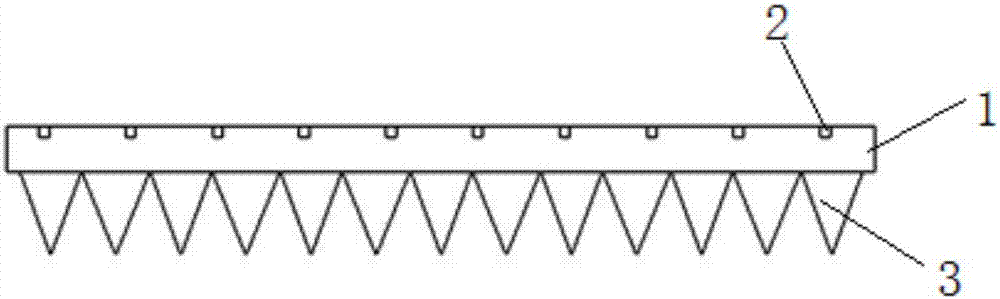

[0032] Such as Figure 1~3 As shown, a metal grid flexible conductive film with high light transmittance includes a flexible base layer 1, a metal grid layer 2 on one side, and a UV-cured nanostructure layer 3 on the other side. The metal grid layer 2 plays the role of conduction, and the UV-cured nanostructure layer 3 plays the role of increasing light transmittance.

[0033] The flexible base layer 1 is a transparent, bendable polymer material, including common PET, PEN, PI, PPS, PC, PES, PEI, PAR or PCO flexible polymer materials.

[0034] The metal grid layer 2 is a conductive grid layer obtained by rolling linear intersecting grooves on the surface of the flexible base layer, then coating silver paste into the linear intersecting grooves, baking and cleaning.

[0035] The UV-curable nanostructure layer 3 is a transparent glue with UV-curable function, which is formed by UV-curing after embossing on the flexible base layer to form a nanostructure array with improved light...

Embodiment 2

[0048] A metal grid flexible conductive film with high light transmittance comprises a flexible base layer, a metal grid layer on one side and a UV curable nanostructure layer on the other side. The metal grid layer plays the role of conduction, and the UV-cured nanostructure layer plays the role of increasing light transmittance.

[0049] The flexible base layer is PET.

[0050] The metal grid layer is a conductive grid layer obtained by rolling linear intersecting grooves on the surface of the flexible base layer, then coating silver paste into the linear intersecting grooves, baking and cleaning. The linear intersecting grooves are composed of two groups of parallel linear grooves intersecting at an angle of 10°, wherein the groove width of each linear groove is 50nm, and the distance between adjacent linear grooves is 100nm.

[0051] The UV-curable nanostructure layer is a transparent glue with UV-curable function, which is formed by UV-curing after embossing on the flexi...

Embodiment 3

[0053] A metal grid flexible conductive film with high light transmittance comprises a flexible base layer, a metal grid layer on one side and a UV curable nanostructure layer on the other side. The metal grid layer plays the role of conduction, and the UV-cured nanostructure layer plays the role of increasing light transmittance.

[0054] The flexible base layer is PCO flexible polymer material.

[0055] The metal grid layer is a conductive grid layer obtained by rolling linear intersecting grooves on the surface of the flexible base layer, then coating silver paste into the linear intersecting grooves, baking and cleaning. The linear intersecting grooves are composed of two groups of parallel linear grooves intersecting at an angle of 90°, wherein the groove width of each linear groove is 10 μm, and the distance between adjacent linear grooves is 500 μm.

[0056] The UV-curable nanostructure layer is a transparent glue with UV-curable function, which is formed by UV-curing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com