Mechanized crop rotation method for corn and soybeans in northeast ridge planting region

A technology for ridge farming and corn, applied in the field of agronomy, can solve the problems of large soybean planting area, difficult operation of no-tillage seeders, and large amount of straw that is not easy to rot, so as to ensure planting density, improve water storage and moisture conservation capacity, and reduce The effect of soil erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Describe technical scheme of the present invention in detail below in conjunction with accompanying drawing:

[0019] A method for mechanized rotation of corn and soybeans in a ridge cropping area in Northeast China, comprising: planting corn in the first year, planting soybeans in the second year, and planting corn in the third year, and so on. The specific method is as follows:

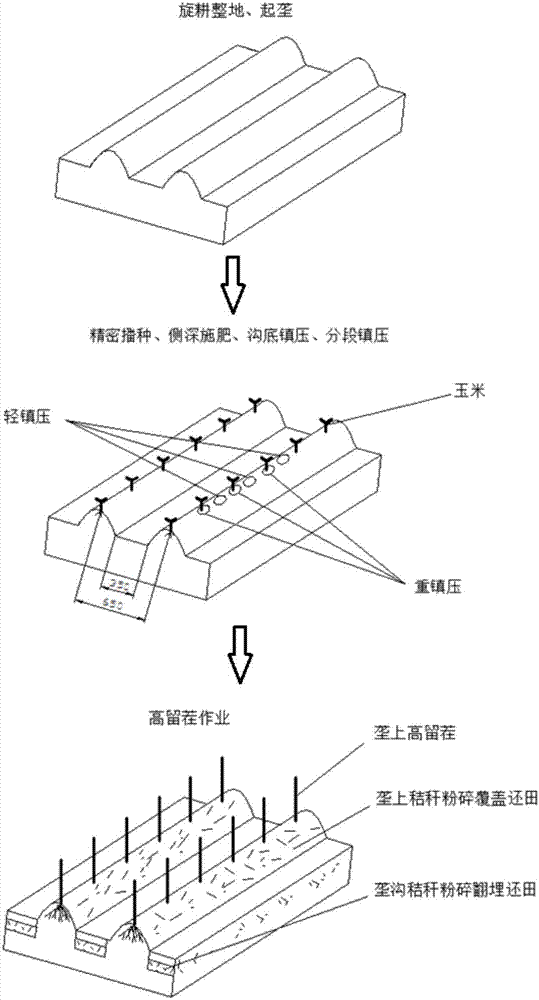

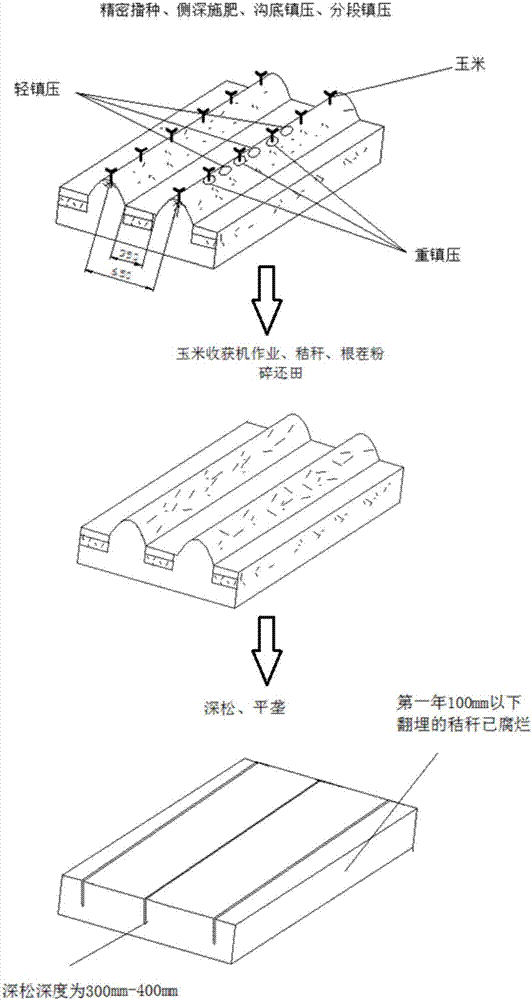

[0020] The first year of crop rotation: combined operations of rotary tillage, ridging, and sowing are adopted in spring, and corn is planted in the middle of Longshang. Intertillage and weeding and topdressing are used in mid-to-late June. The operation method of combining stubble and crushing and returning to the field is adopted;

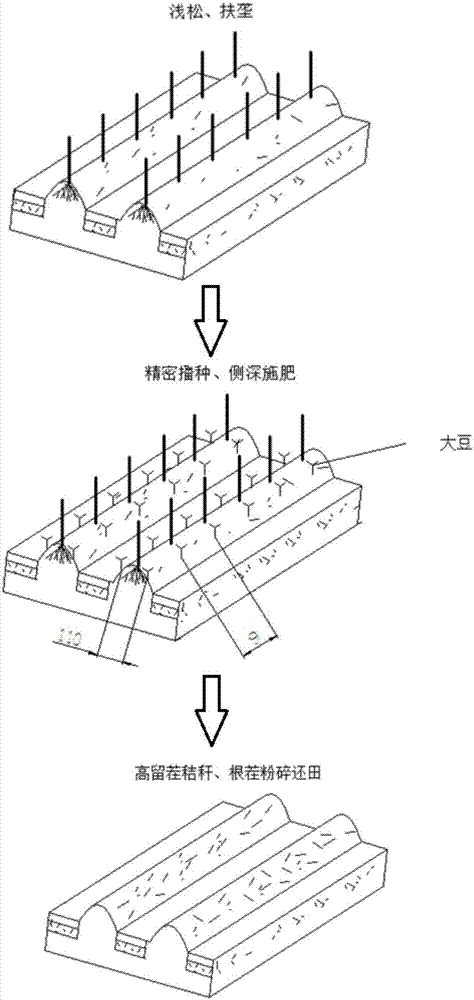

[0021] The second year of crop rotation: Combine shallow pine (shallow pine depth 15-25mm), ridge support, and sowing in spring, soybeans are sown on both sides of the ridge, intertillage, weeding, and top dressing in mid-to-late June, and harvested in autumn, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com