Self-locking type overturning high-pressure forming machine

A high-pressure molding machine and self-locking technology, which is applied to ceramic molding machines, supply devices, unloading devices, etc., to achieve the effects of ensuring safety, preventing equipment damage, and reducing equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

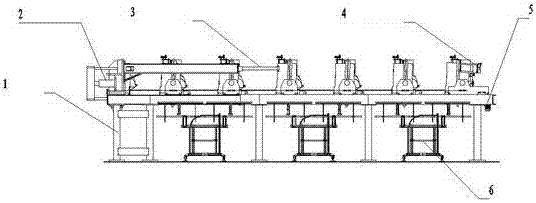

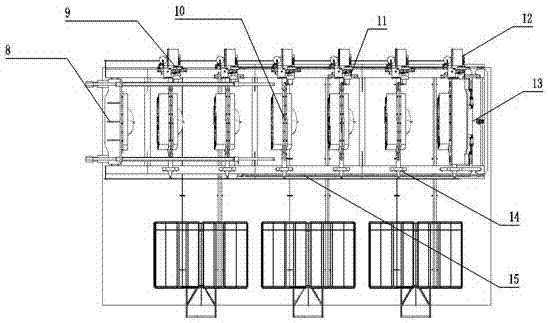

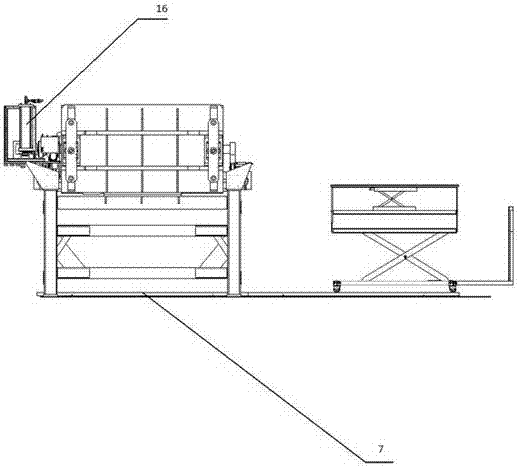

[0023] The structural features of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0024] A self-locking reversible high-pressure molding machine, including a main frame 1 for carrying the overall mechanism, a mold trolley A11 and a mold trolley B14 for carrying the mould, a main base plate 8, an intermediate base plate 10 and an end base plate for fixing the mold 13. Self-locking mechanism for mold self-locking, turning mechanism for mold turning, mold opening and closing mechanism for mold opening and closing, mud pressurizing mechanism for pressurizing mud, self-locking mechanism for A hydraulic device that provides hydraulic power, a pressure sensor and a control device. The self-locking mechanism includes a clamping cylinder 2 installed on the main board 8, and the end of the cylinder rod 3 of the clamping cylinder 2 is provided with a locking head B. The locking head B is an elliptical female ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com