Negative oxygen colorful paint and its preparation method

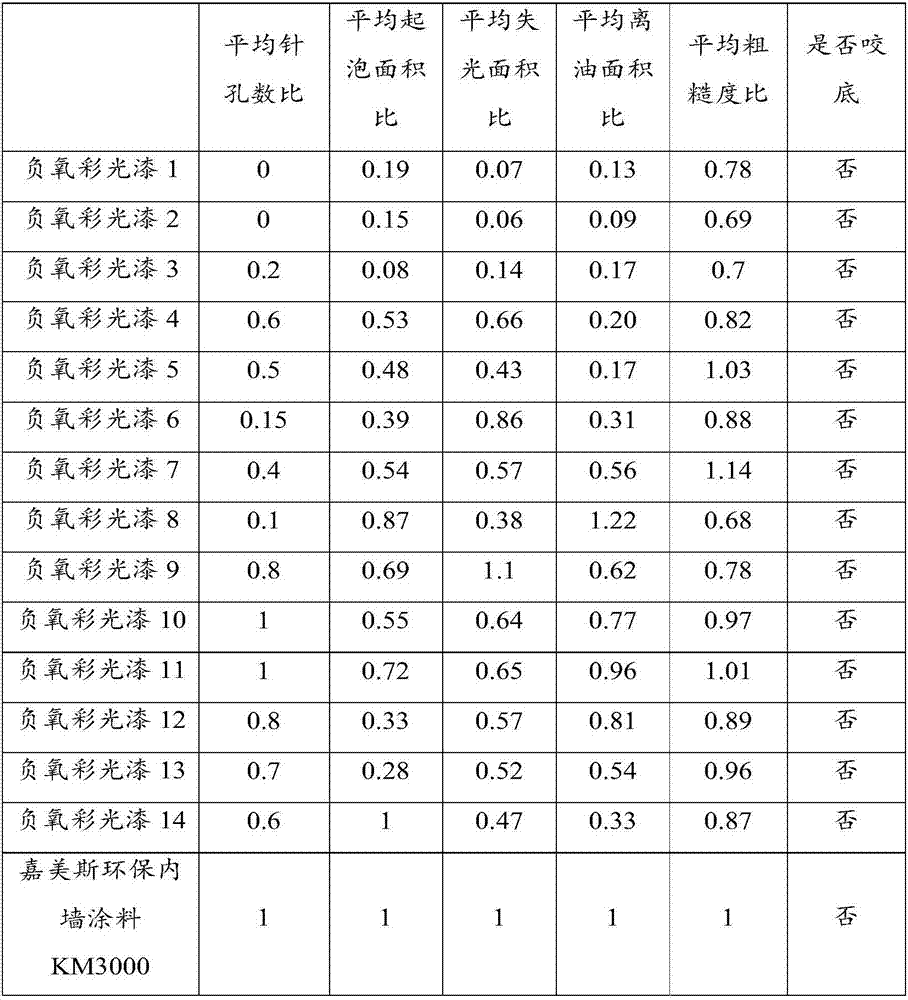

A color light and negative oxygen technology, applied in the field of art paint, can solve the problems of discounting the service life of the paint film, reducing the use experience, and fading the color depth, etc., and achieves the effect of convenient deployment, remarkable anti-aging performance, and not easy to fade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

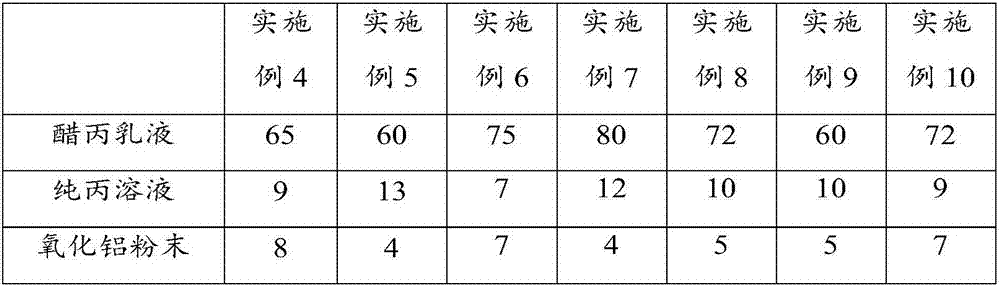

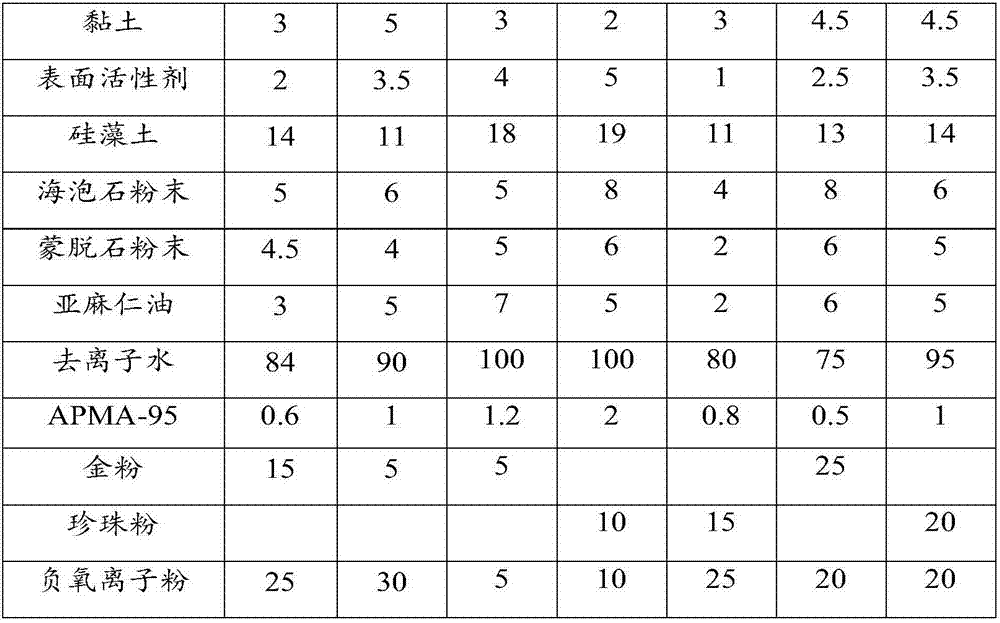

Examples

preparation example Construction

[0044] The embodiment of the present invention also provides a preparation method of the above-mentioned negative oxygen gloss paint, which includes a pretreatment step and a mixing step.

[0045] In the pretreatment step, the sepiolite powder and montmorillonite powder are mixed and stirred evenly to obtain a mixed powder, and 20-35 parts of deionized water, 0.1-0.2 parts of APM-95, 0.8-1.2 parts of surface Active agent, all alumina powder and all clay, and stirred for 5-15 minutes to obtain the first intermediate.

[0046] The pretreatment step can make the sepiolite powder and montmorillonite powder absorb water in advance, and prevent the raw material components of the negative oxygen glossy paint from being absorbed by the sepiolite powder and the montmorillonite powder in the mixing step of the negative oxygen glossy paint Wrapped in sepiolite powder or montmorillonite powder, to ensure that both sepiolite powder and montmorillonite powder can perform the water balance f...

Embodiment 1

[0052]This embodiment provides a kind of raw material of negative oxygen gloss paint, and this raw material comprises by weight: 70 parts of vinegar acrylic emulsion, 10 parts of pure acrylic emulsion, 6 parts of alumina powder, 3.5 parts of clay, 3 parts of surfactant, 15 parts of diatomaceous earth, 6 parts of sepiolite powder, 5 parts of montmorillonite powder, 5 parts of linseed oil, 86 parts of deionized water, 0.8 parts of APM-95, 30 parts 25 parts of pearl powder and 25 parts of negative oxygen ion powder.

Embodiment 2

[0054] The present embodiment provides a kind of raw material of negative oxygen gloss paint, and this raw material comprises by weight: 68 parts of vinegar acrylic emulsion, 11 parts of pure acrylic emulsion, 5 parts of alumina powder, 3 parts of clay, 3.5 parts of surfactant, 17 parts of diatomaceous earth, 7 parts of sepiolite powder, 5.5 parts of montmorillonite powder, 4.5 parts of linseed oil, 88 parts of deionized water, 0.6 parts of APM-95, 25 parts 15 parts of pearl powder and 15 parts of negative oxygen ion powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com