Hemp peeling knife

The technology of hemp knife and blade is applied in the field of hemp knife, which can solve the problems of difficult transportation, easy injury to users, inconvenient use, etc., and achieves the effects of convenient retting and degumming treatment, easy production and processing, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

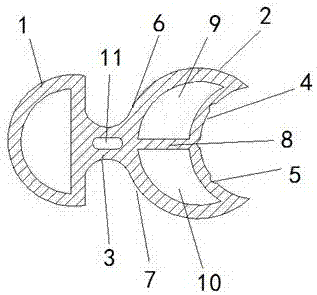

[0016] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0017] In order to achieve the above object, the present invention adopts the following technical solutions: a hemp peeling knife, comprising a grip portion 1, an arc-shaped transition connection portion 3 and a blade portion 2; the grip portion 1 connects the transition connection portion 3 and the The blade portion 2 is connected, the grip portion 1 is half-moon, and the blade portion 2 is crescent-shaped; the blade portion 2 includes an arc-shaped back and an arc-shaped edge, and the arc-shaped back and the arc-shaped edge There is a straight line connecting part 8 before; the arc-shaped back and the arc-shaped edge are both horizontal axis-symmetrical structures, the arc-shaped back includes an upper arc-shaped segment 6 and a lower arc-shaped segment 7, and the arc-shaped edge in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com