High-proportion copper alginate fiber blended yarn and preparation method

A copper alginate fiber, a high-proportion technology, applied in yarn, textiles and papermaking, spray/jet textile material processing, etc., can solve the problems of copper alginate conductive fibers, etc., to improve the anti-pilling performance, improve Warmth retention, effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

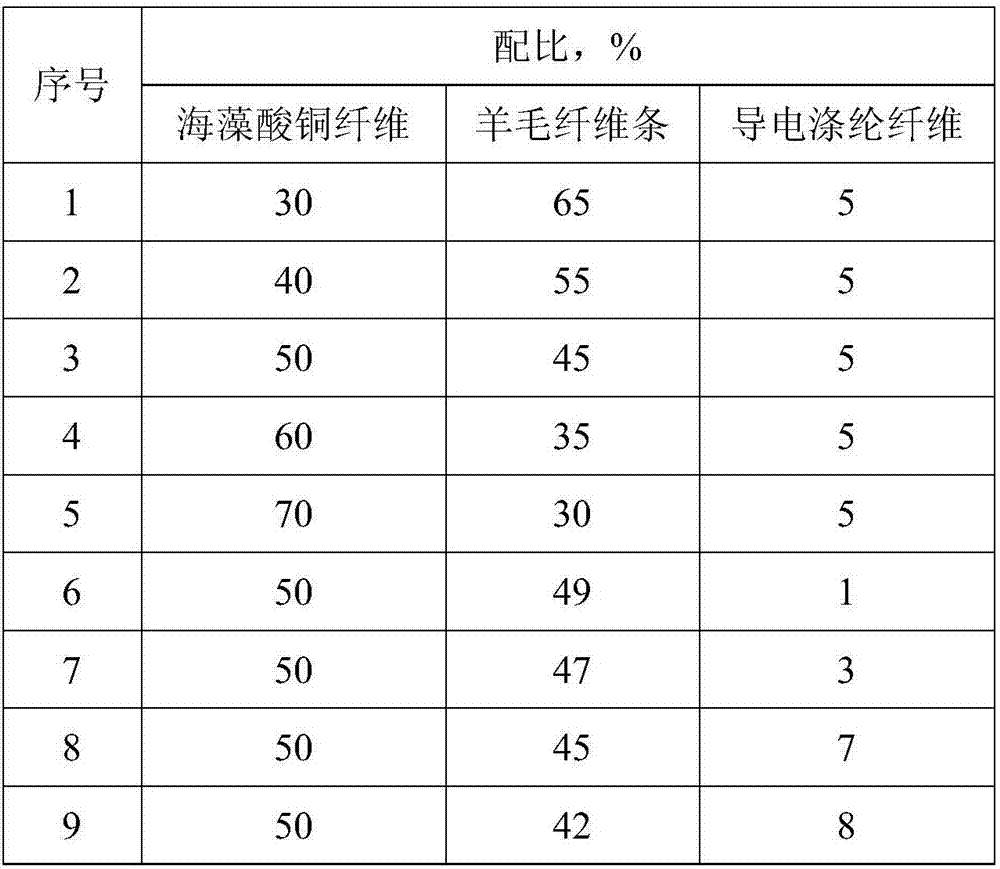

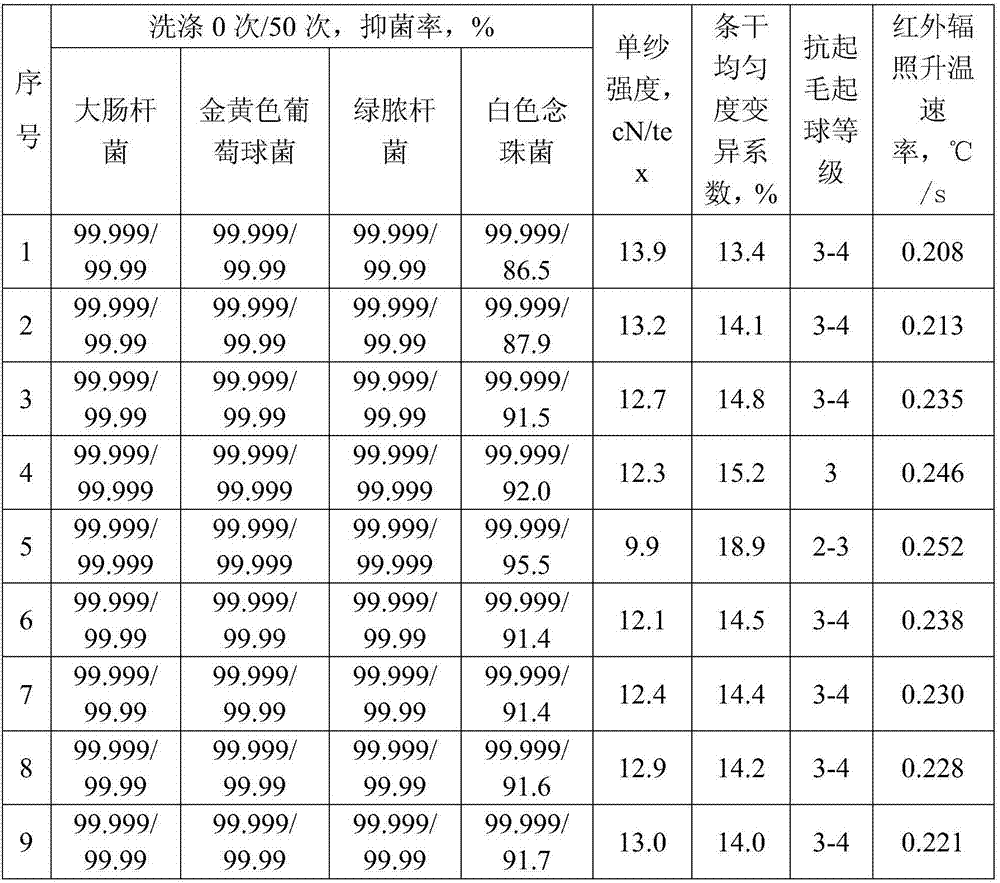

[0032] Embodiment 1: the different proportioning test that does not contain acrylic fiber blended yarn (taking 18.2tex blended yarn as example)

[0033] Copper alginate fiber, wool, and conductive polyester fiber are used as raw materials, and the ratio of raw materials is shown in Table 1.

[0034] Table 1 Proportion composition table of blended yarn raw materials

[0035]

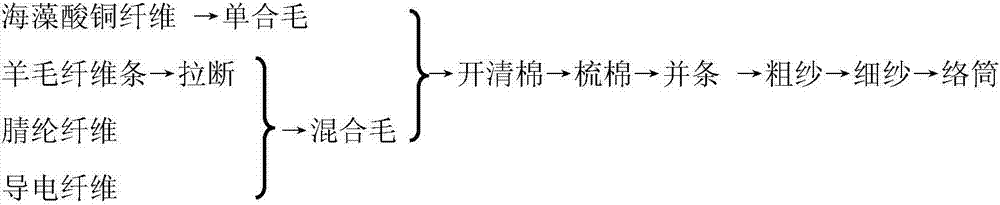

[0036] The copper alginate fibers in the proportion shown in Table 1 were separately blended into wool, wool and conductive polyester fibers were mixed, and the fibers of single wool and blended wool were mixed in order to perform opening and cleaning, carding, and blending. Sliver, roving, spun yarn and winding to form blended yarn, the specific process is as follows:

[0037] (1) Wool blending process: before the wool is blended, the wool is broken first, that is, 8 wool tops are fed into the breaking machine at a speed of 6m / min, and then the fiber is pre-mixed and opened together with the conducti...

Embodiment 2

[0045] Embodiment 2: the different proportioning test (taking 21.1tex blended yarn as example) containing acrylic fiber blended yarn

[0046] Copper alginate fiber, wool, acrylic fiber, and conductive polyester fiber are used as raw materials, and the ratio of raw materials is shown in Table 3.

[0047] Table 3 Proportion composition of blended yarn raw materials

[0048]

[0049] The copper alginate fibers in the proportions shown in Table 3 were separately blended into wool, and after wool and conductive polyester fibers were mixed, the fibers of the single wool and the fibers of the blended wool were mixed in order to open and clean cotton, carding, and blending. Sliver, roving, spun yarn and winding to form blended yarn, the specific process is as follows:

[0050] (1) Wool blending process: before the wool is blended, the wool is broken first, that is, 12 wool tops are fed into the breaking machine at a speed of 4m / min, and then the fiber is pre-mixed and opened toget...

Embodiment 3

[0059] Example 3: Effect of pretreatment

[0060] Experiments with different pretreatment processes were carried out with the ratio of alginate copper fiber / wool / conductive polyester fiber 58 / 40 / 2, the amount of smoothing agent and softening agent was controlled at 1.5%, and the oil-water ratio of smoothing agent and softening agent was respectively controlled as 1:2, 1:3, 1:4, 1:6, 1:8, 1:10, 1:12, 1:15, other conditions are the same as in Example 1, and the serial numbers in Comparative Example 3 and Example 1 In the scheme corresponding to 10, it can be seen that when the oil-water ratio of the smoothing agent and the softening agent is low, the viscosity of the smoothing agent and the softening agent is relatively high, which can play a good pretreatment effect, but the dispersion uniformity is not good. With the increase of the oil-water ratio of smoothing agent and softener, when the oil-water ratio exceeds 1:5, the dispersion uniformity and pretreatment effect are bette...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com