Double-bundle screen asymmetric composite yarn, spinning method and applications

A composite spinning, asymmetric technology, used in spinning machines, continuous winding spinning machines, yarns, etc. The mechanism is practical, the yarn structure is stable, and the spinnable count is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

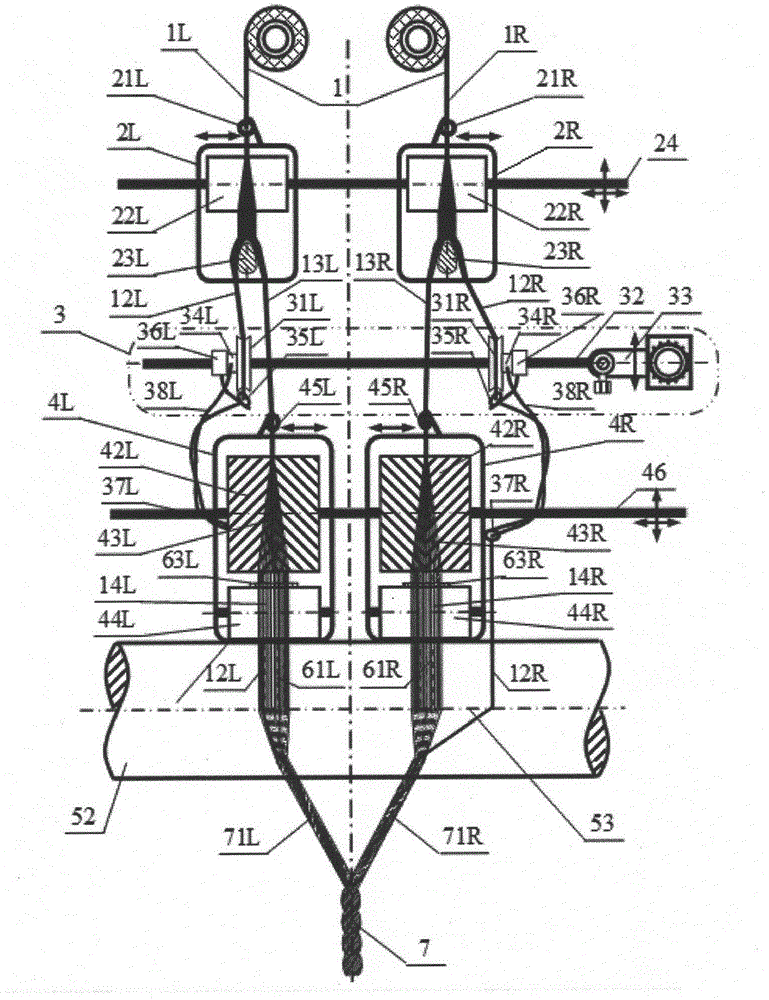

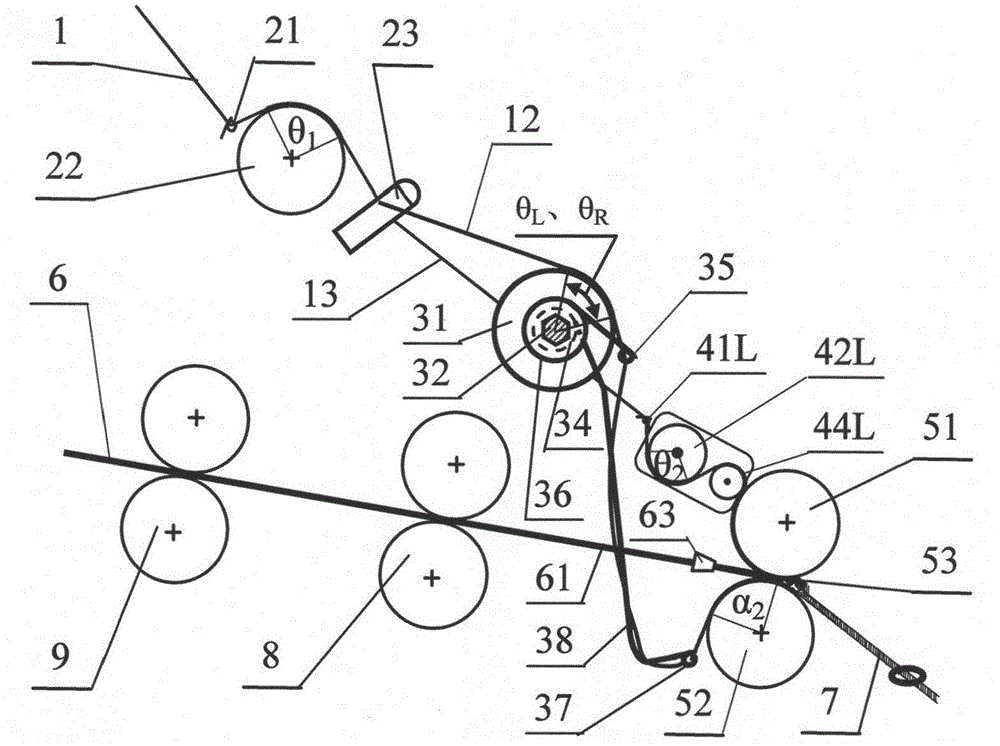

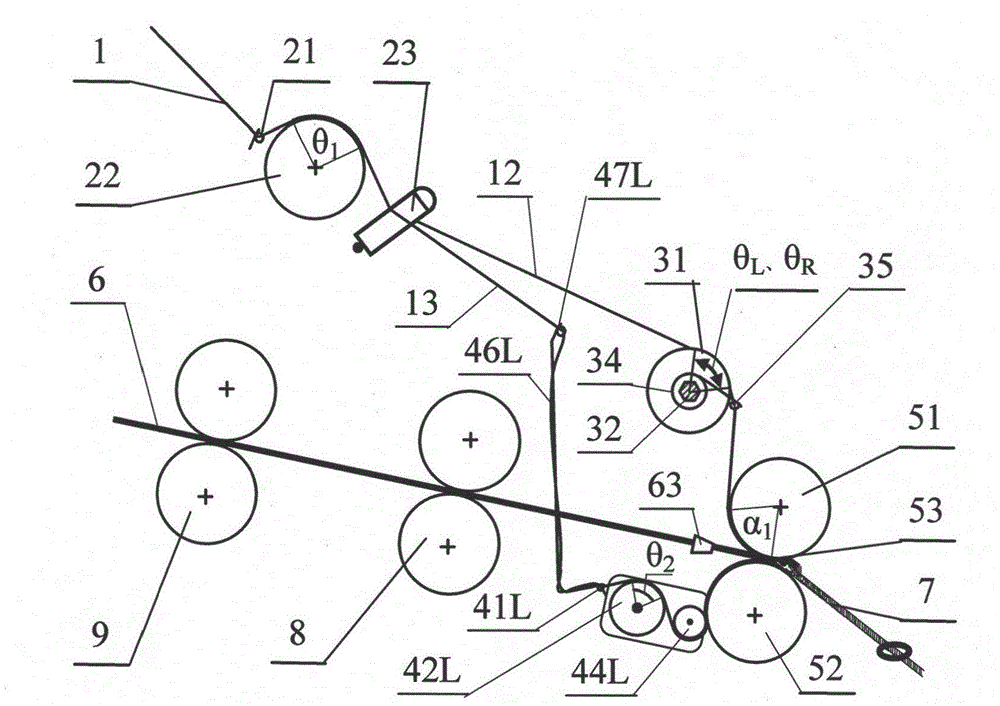

[0088] Embodiment 1: Recycling the composite yarn of cotton / viscose filament asymmetric net-wrapped core-spun yarn

[0089] Adopt the compound spinning method that is used for double-bundle network symmetric composite yarn of the present invention, get two bundles of viscose long filaments and be divided into left tow 12L and left mesh tow 13L and linear density that are not equal in linear density The right wire bundle 12R and the right mesh wire bundle 13R. Left tow 12L after splitting and right tow 12R are adjusted its tension through left tension disc 31L and right tension disc 31R respectively and through left upper line guide wire hook 32L and right upper line guide wire hook 32R to adjust left tension disc 31L and right Surrounding angle θ of tension disc 31R L and enveloping angle θ R The tension of the left tension disc 31L to the left tow 12L is less than the tension of the right tension disc 31R to the right tow 12R, through the left downward guide wire hook 37L a...

Embodiment 2

[0090] Embodiment 2: cashmere / silk filament asymmetrical net wrapped close to the composite yarn of the yarn

[0091] Using the compound spinning method for double-bundle mesh symmetrical composite yarn of the present invention, take two bundles of silk and split them into left tow 12L with unequal linear density, left mesh tow 13L and right tow 12R with unequal linear density With right mesh tow 13R. Adjust the tension of the split left tow 12L and right tow 12R through the left tension disc 31L and the right tension disc 31R and adjust the tension of the left tension disc 31L and the right through the left upper guide wire hook 32L and the right upper guide wire hook 32R Surrounding angle θ of disk 31R L and enveloping angle θ R The tension of the left tension disc 31L to the left tow 12L is equal to the tension of the right tension disc 31R to the right tow 12R, and the left upper guide wire hook 35L and the right upper guide wire hook 35R are fed in close to the front uppe...

Embodiment 3

[0092] Embodiment 3: the composite yarn of kapok / polyester filament mesh wrapping yarn

[0093] Adopt the compound spinning method that is used for double-bundle net symmetrical composite yarn of the present invention, take two bundles of polyester long filaments and split into the left silk bundle 12L of linear density and the left wire bundle 13L and the right silk of linear density different Bundle 12R with right mesh wire bundle 13R. Adjust the tension of the split left tow 12L and right tow 12R through the left tension disc 31L and the right tension disc 31R and adjust the tension of the left tension disc 31L and the right through the left upper guide wire hook 32L and the right upper guide wire hook 32R Surrounding angle θ of disk 31R L and enveloping angle θ R The tension of the left tension disc 31L to the left tow 12L is greater than the tension of the right tension disc 31R to the right tow 12R, and the left upper guide wire hook 35L and the right upper guide wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com