Microfiber synthetic leather direct dyeing machine

A dyeing machine and synthetic leather technology, applied in the field of dyeing machines, can solve problems such as low efficiency, waste of resources, and inconvenient use, and achieve the effects of improving heat exchange efficiency, saving energy, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

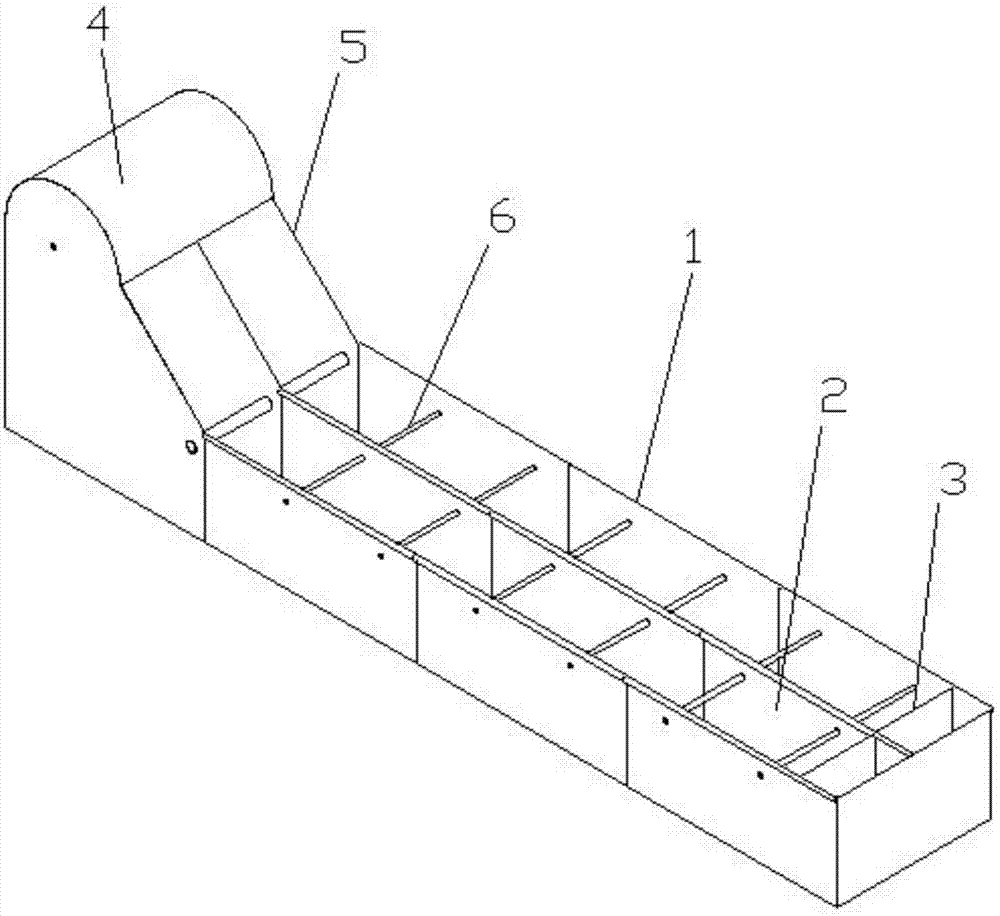

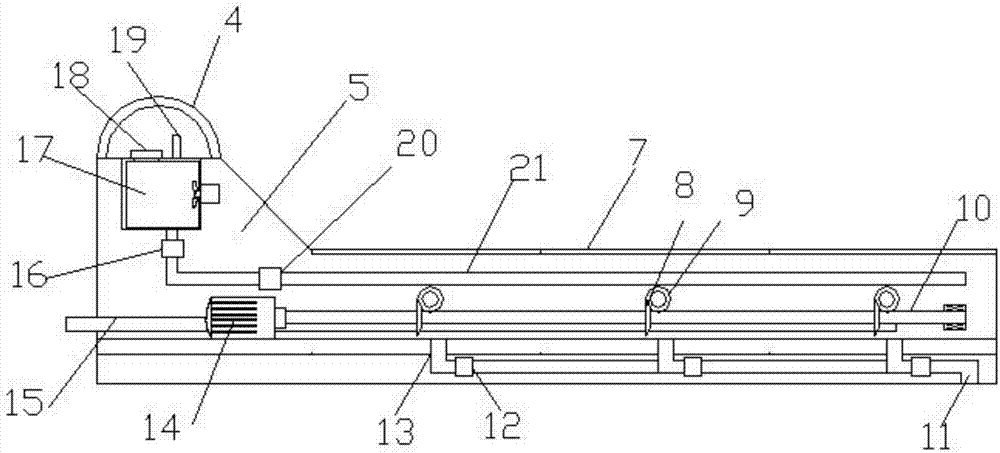

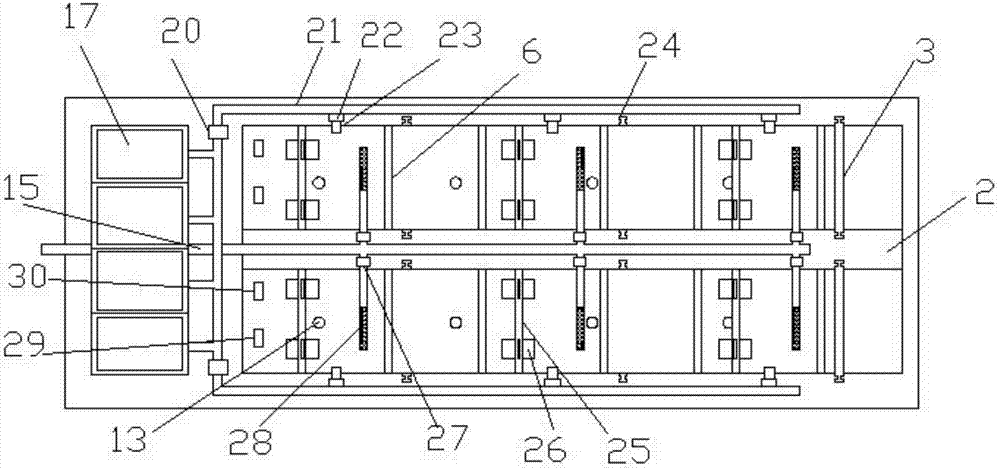

Embodiment approach

[0030] Implementation method: the cover plate 7 of the body is made of glass fiber reinforced plastic, which is convenient for observing the operation of the microfiber cloth in the vat during the dyeing process, and prevents the occurrence of defects such as uneven dyeing and uneven shades caused by the blocking of the overflow dyeing machine. The plugboard 3 is inserted in different slots 24, which can change the internal volume of the cylinder body 1, thereby adapting to different batches of dyeing operations to save water resources and energy. The stirring motor 14 drives the stirring blade 26 to rotate, so as to realize the dyeing in the cylinder body 1. Stir evenly to increase the dyeing quality. The heating steam is transported through the steam delivery pipe 15 and directly enters the interior of the cylinder body 1. It is directly heated and effectively utilizes the waste heat of steam condensate to increase the heating efficiency. The waste water flows out through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com