Manufacturing method for prefabricated concrete component with connecting steel bars

A prefabricated concrete and steel bar connection technology, which is applied in the direction of building construction and construction, can solve the problems of insufficient connection integrity of precast concrete components, complicated component transportation, installation and steel bar connection, and complicated manufacturing process, so as to save mold types and Quantity, improved production quality, and increased versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The method for manufacturing the prefabricated concrete member with connecting steel bars of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

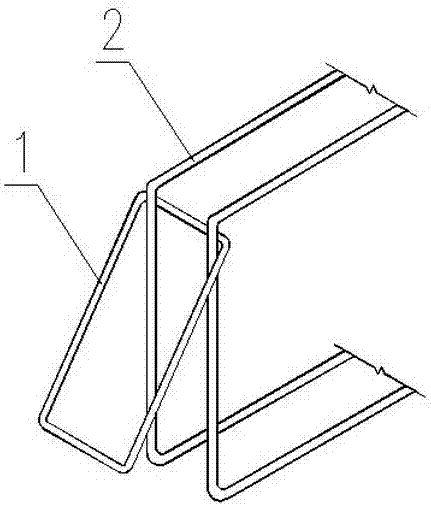

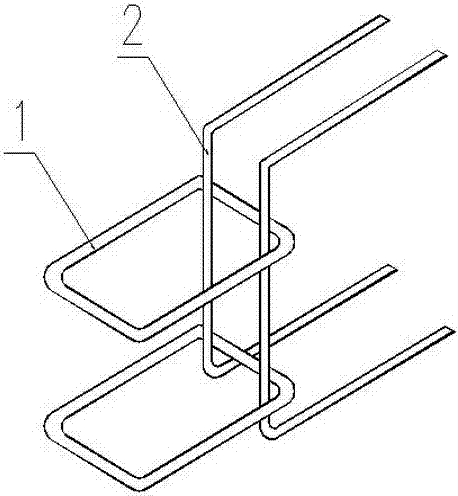

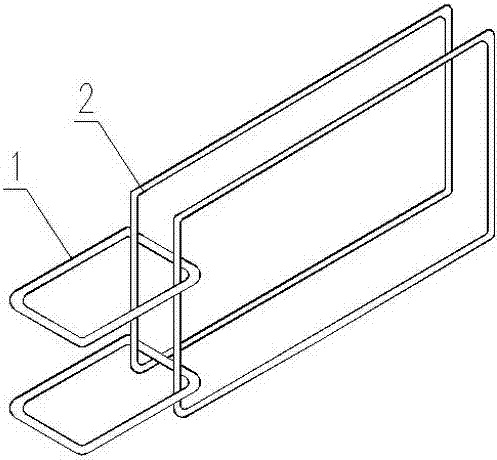

[0022] The method for making prefabricated concrete elements with connecting steel bars proposed by the present invention is used to make prefabricated concrete elements with connecting steel bars hanging on the sides, and an embodiment of the prefabricated concrete elements is as follows: Figure 9 , Figure 9 The middle shaded part is a section plane; one end of the connecting steel bar 1 is hung on the precast concrete member, that is, hung on the steel skeleton on the precast concrete member, and the other end is a free end. The manufacturing method includes: (1) Binding the reinforcement skeleton of the prefabricated concrete member, the connection reinforcement 1 is hung on the reinforcement skeleton 2, and an embodiment of the combination of the reinfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com