Pit-in-pit novel framework supporting system and construction method thereof

A construction method and pit-in-pit technology, which is applied in the direction of formwork/formwork/work frame, wine cellar, building components, etc., can solve the problem that the bottom of the pit in the pit cannot be vibrated, and the surface, floating, and the height difference in the pit can be solved. Insufficient and other problems, to achieve the effect of ensuring the plane size and the flatness of the side wall, easy operation and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

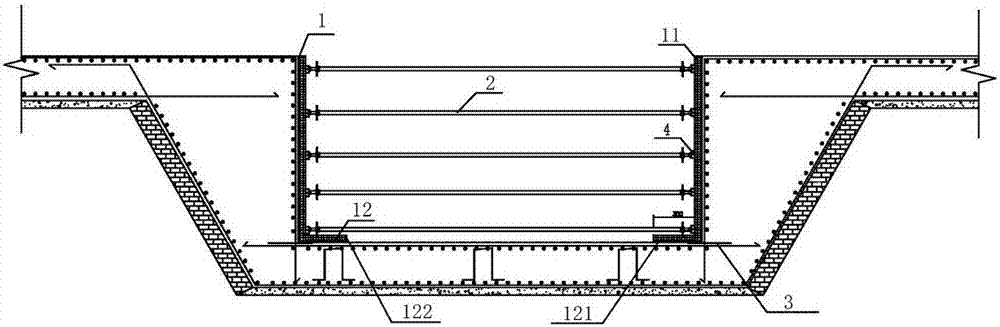

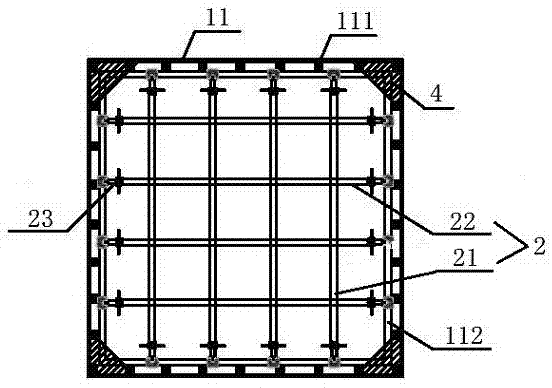

[0022] Such as figure 1 , 2 As shown, a new type of pit-in-pit formwork support system in this embodiment mainly includes a box mold 1 and a support 2. The box mold 1 is a box-shaped formwork with an upper opening, consisting of a side formwork 11 and a bottom formwork 12. The support 2 includes a longitudinal support 21 and a transverse support 22 . The bottom template 12 is composed of four strip templates 121 with a width of 200 mm, which are circularly spliced to form a hollow bottom template with an opening in the middle. The bottom formwork 12 is provided with square wood 122, and the side formwork 11 is provided with vertical inner corrugation 111 and horizontal outer corrugation 112. The vertical inner corrugation 111 adopts high-quality square wood, and the horizontal outer corrugation 112 adopts double steel pipes. The support 2 is compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com