Productivity testing real-time adjustment method of offshore oil well

A real-time adjustment, oil well technology, used in earthmoving, wellbore/well components, etc., can solve problems such as failure to fully reflect reservoir productivity, reduce the validity of test data, and lack of bottom-hole pressure data in test plans, and achieve savings. Test time and cost, optimize and adjust the test system, reduce the effect of test risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

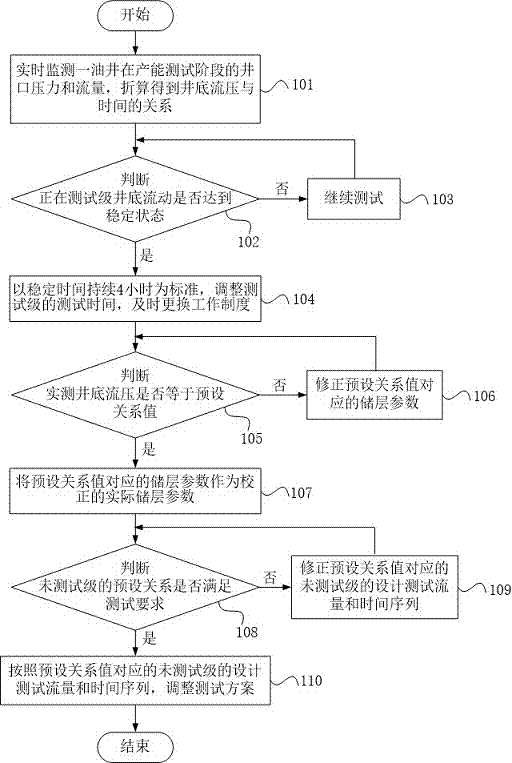

[0035] figure 1 It is a flow chart of the well test analysis and control method for a horizontal well with staged liquid production in an embodiment of the present invention. The real-time adjustment method in this embodiment takes into account the influence of the staged liquid production of a horizontal well, and specifically includes the following steps:

[0036] 101: Real-time monitoring of the wellhead pressure and flow rate of the oil well during the productivity testing stage, and convert the relationship between the bottom hole pressure and time;

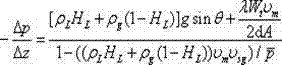

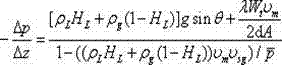

[0037] Specifically, the Beggs-Brill method is used to convert the wellhead pressure to the bottomhole pressure, which is suitable for the calculation of gas-liquid two-phase flow in horizontal wells, vertical wells and directional wells. The basic equation is:

[0038]

[0039]Among them, p is the pressure, the unit is Pa; z is the length along the wellbore direction, the unit is m; λ is the flow resistance coefficient,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com