Automatic torsion detection machine

A torque testing machine and torque technology, applied in measuring devices, power metering, instruments, etc., can solve the problems of large deviation of the results, unstable test results, unsuitable detection, etc., to improve the detection accuracy, save manpower and Effect of detection time, reduced workload and skill requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

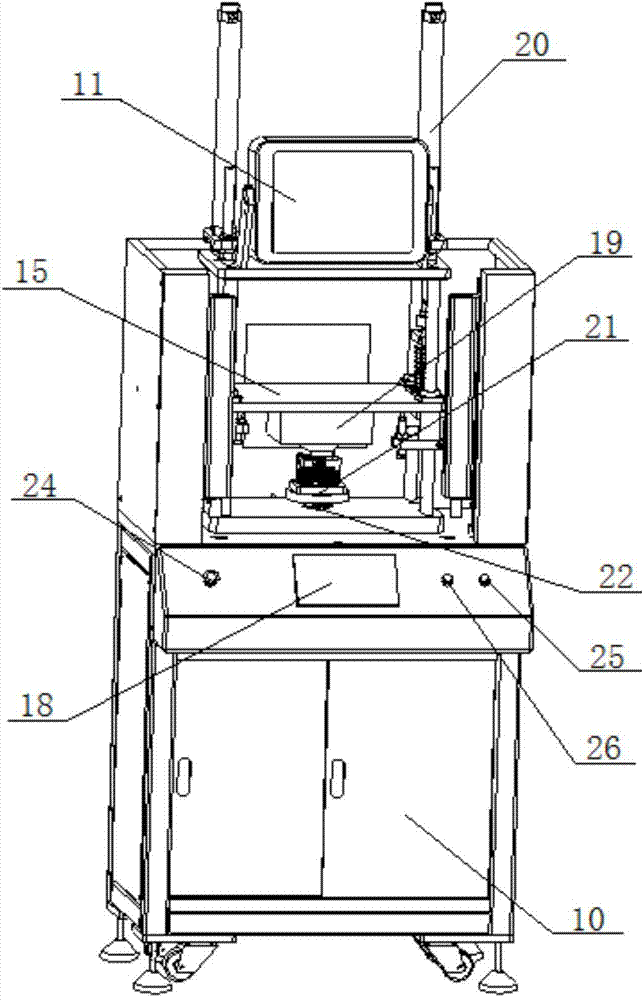

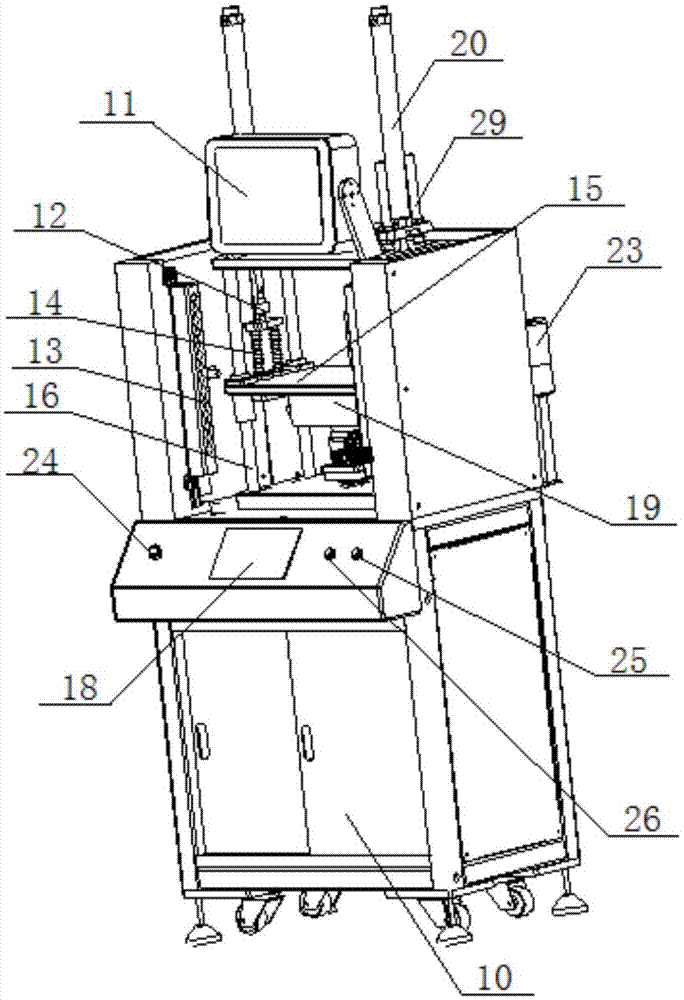

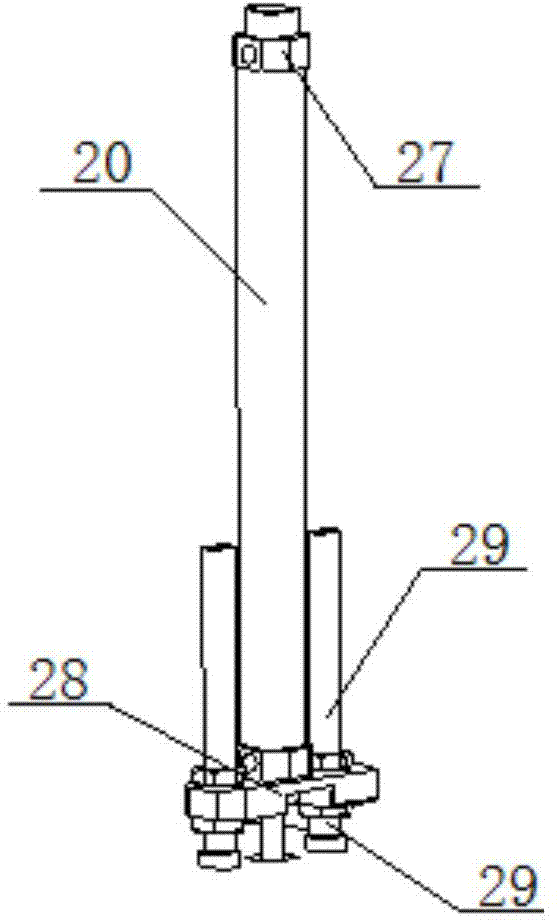

[0031] As shown in 1 to 4, the schematic structural diagram of the automatic torque detection machine of the present invention includes an electric control box 10, a touch screen 11, a floating joint 12, a safety protection grating 13, a buffer spring 14, an upper and lower movable plate 15, a guide post 16, and a fixed tooling 17. Torque display screen 18, torque detector 19, cylinder 20, torque detection positioning head 21, rotating motor 22, alarm light 23, emergency stop button 24, reset button 25, start button 26, air pipe joint 27, cylinder fixing plate 28 , height adjustment screw 29, lock nut 30, shaft washer 31, upper friction plate 32 of the rotating shaft, upper cover of the rotating shaft 33, lower friction plate of the rotating shaft 34, second gasket of the rotating shaft 35, lower cover of the rotating shaft 36, spring washer of the rotating shaft 37 And rotating shaft central axis 38.

[0032] The torque detection chamber is arranged on the top of the electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com