Mine anchoring and shotcreting de-dusting feeder

A technology of feeder and anchor shotcrete, which is applied in shaft lining, bolt installation, mining equipment, etc., can solve problems such as low efficiency, no dust removal feeding equipment, heavy air pollution in the working environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing.

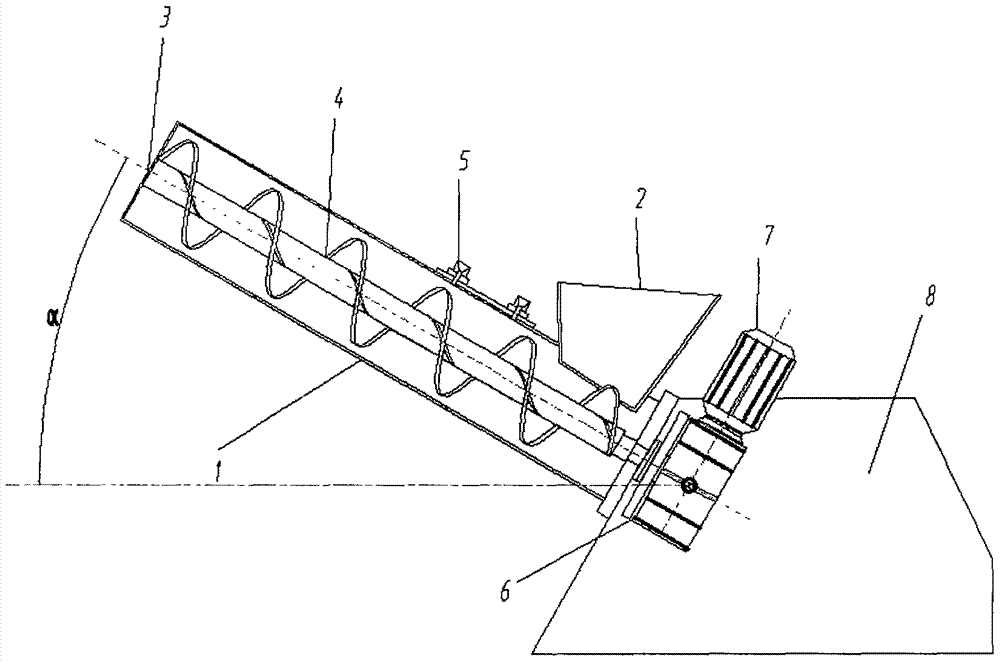

[0012] see as figure 1 As shown, the technical solution adopted in this specific embodiment is: a mine anchor spray dust removal feeder, including a housing 1, a feed port 2, a discharge port 3, a screw screw blade 4, a spray humidification nozzle 5, A reduction box 6, a motor 7, and a bracket 8, the motor 7 is connected to the reduction box 6 through transmission; the housing 1 is provided with a spraying and humidifying water nozzle 5, and the spraying and humidifying water nozzle 5 extends into the housing 1; The housing 1 is connected with the bracket 8, and the angle α between the housing 1 and the horizontal plane is an acute angle; the housing 1 is equipped with a screw helical blade 4, and one end near the reduction box 6 is provided with a feed port 2 and a discharge port 3 is arranged at the tail end of the screw helical blade 4; the fixed end of the screw helica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com