Dust-fall method for coal body in extra-thick fully-mechanized caving face through high-pressure water injection

A fully-mechanized caving face and coal body technology, which is applied in the field of high-pressure water injection and dust reduction for extra-thick fully-mechanized caving face coal bodies, can solve problems such as the lack of dust concentration control methods, and achieve significant dust reduction effects, reduced dust rates, and obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

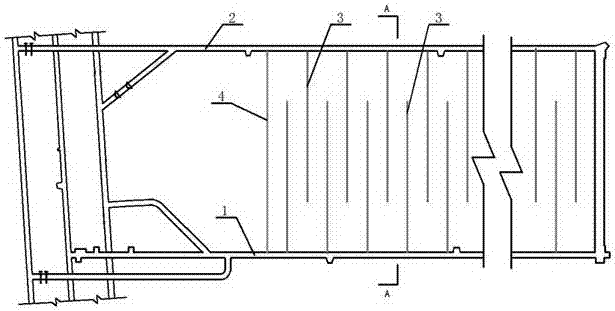

[0014] The present invention is set forth below in conjunction with embodiment and accompanying drawing of specification sheet: the average coal seam thickness of the coal body working face of extra-thick fully mechanized caving face in a certain coal mine is 13m, the inclination length is 200m, and the strike length is 1000m, and the coal seam wetting radius is 12.5m. Caving coal mining technology for mining.

[0015] By adopting the method of high-pressure water injection and dust reduction for extra-thick fully mechanized caving face of the present invention, the following operation steps are implemented:

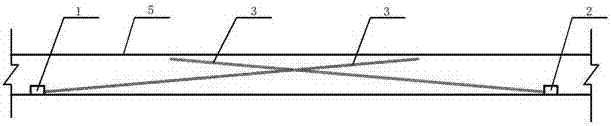

[0016] a. After the mining face is circled, construct the water injection hole 3 in the air inlet trough 1 and the return air trough 2, the hole diameter is φ65mm, the inclination length of the working face is 200, and the drilling depth is determined to be 150m; the average coal seam of the working face The thickness is 13m, and the drilling elevation angle is determine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com