A hydraulic axial pressure generating device for a high-temperature and high-pressure rheometer and its application method

A high-temperature and high-pressure rheological and generating device technology, which is applied in the field of hydraulic axial pressure generating devices for high-temperature and high-pressure rheometers, and ultra-high pressure equipment, can solve the problem of slow response speed of fast switching valves, failure to meet experimental requirements, and failure to reach It is required to switch frequency and other issues to achieve the effect of low noise, low cost and solving interference problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

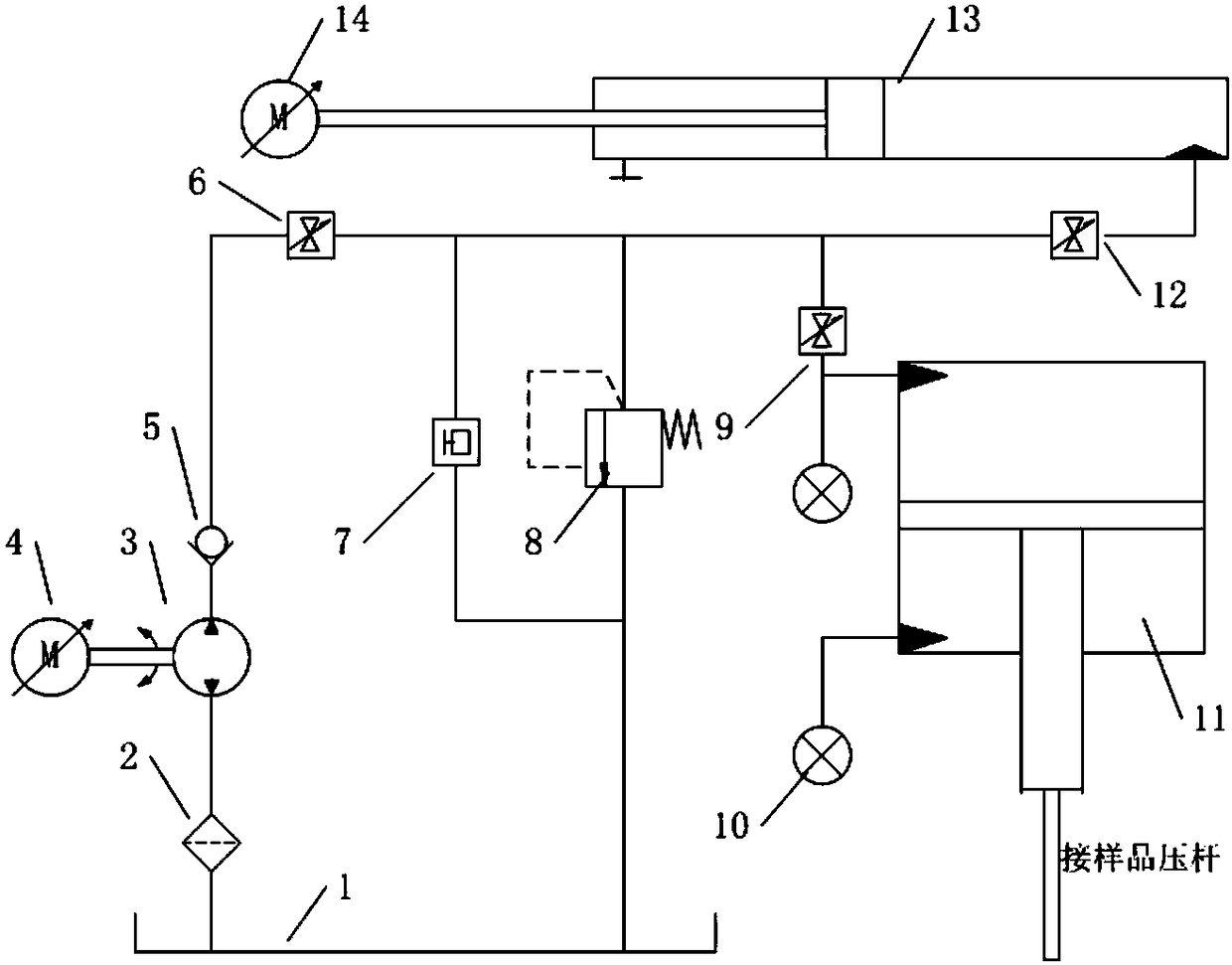

[0027] The present invention will be further described below in conjunction with accompanying drawing.

[0028] like figure 1 As shown, this embodiment provides a hydraulic axial pressure generating device for a high temperature and high pressure rheometer, which includes a fuel tank 1, a filter 2, an oil pump 3, a check valve 5, a plunger cylinder 13, and a booster cylinder 11, controller. The oil pump 3 is driven by the first servo motor 4 to work. The input pipeline of the oil pump 3 is connected to the fuel tank 1 through the filter 2, and the output pipelines are respectively connected with three oil circuits. The first oil circuit is connected to the fuel tank through the oil drain pipeline. The second oil circuit is connected with the oil inlet of the plunger cylinder 13, the third oil circuit is connected with the rodless chamber of the pressurized cylinder 11, and detection elements 10 are arranged at both ends of the pressurized oil cylinder 11. The piston rod end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com