Air spring system for vehicle

A technology of air springs and vehicles, which is applied to vehicle parts, trailers, motor vehicles, etc., and can solve uneconomical problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

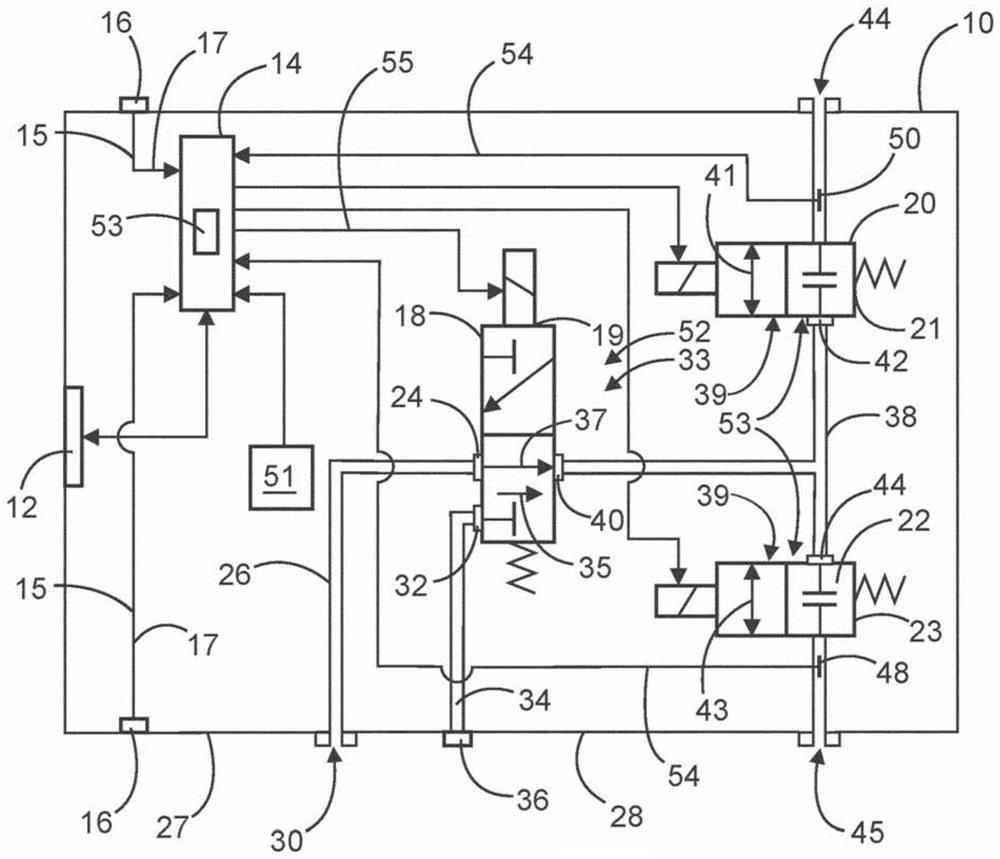

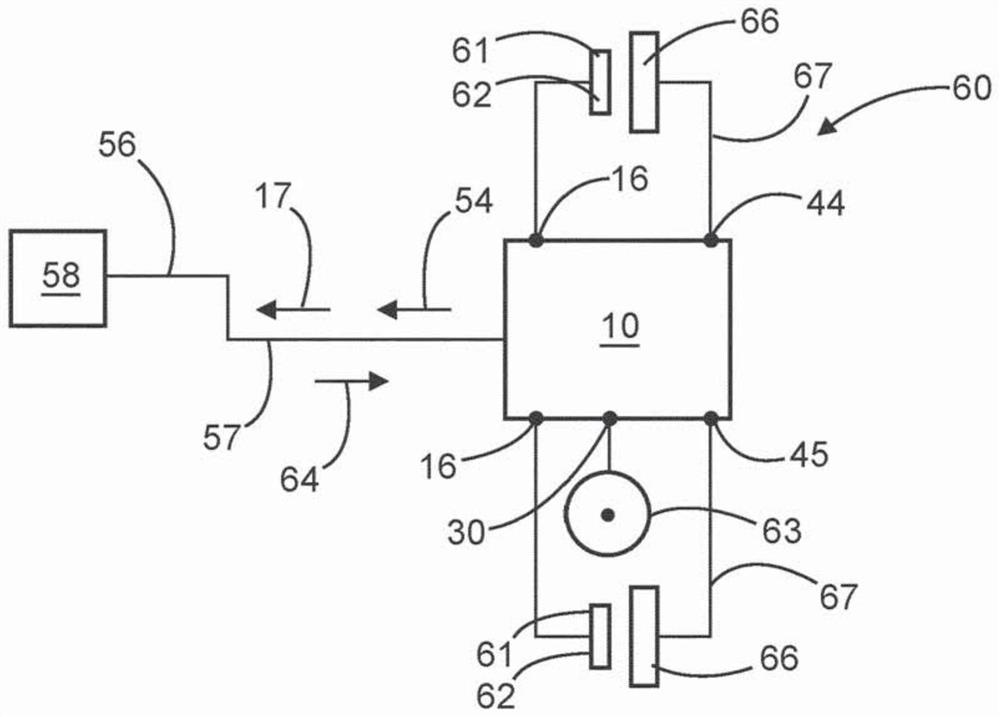

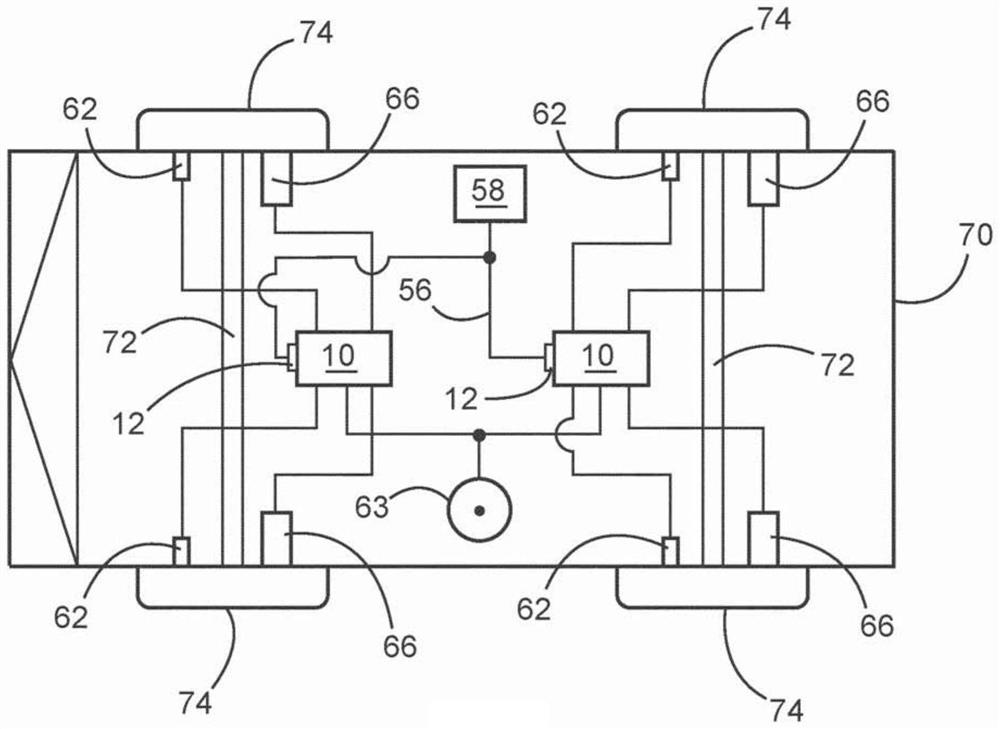

[0042] figure 1 A schematic diagram of a module 10 for an air spring system is shown according to an embodiment. The module 10 includes a data interface 12 which can be connected to a bus, in particular a CAN bus. The data interface 12 is connected to a processing unit 14 , which is likewise connected to other components of the module 10 .

[0043] According to this embodiment, the processing unit 14 is connected to two sensor interfaces 16 to which displacement sensors can be connected. The displacement sensor coupled via the sensor interface 16 provides in particular sensor values 17 which preferably correspond to the displacement sensor values 15 and include, for example, the distance between the wheel suspension and the vehicle chassis. The sensor interface 16 thus serves to receive sensor values by means of the processing unit 14 , wherein the processing unit 14 is able to convert these sensor values into a bus protocol in order to send them via the interface 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com