Small pulsation thin type air compressor

A technology of air compressor and compression mechanism, which is applied in the direction of machine/engine, liquid fuel engine, rotary piston type/oscillating piston type pump components, etc., which can solve the problem of reducing the service life of the motor, the impact of motor power and speed output, and no intersection and other problems to achieve the effect of solving stuck and protecting the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

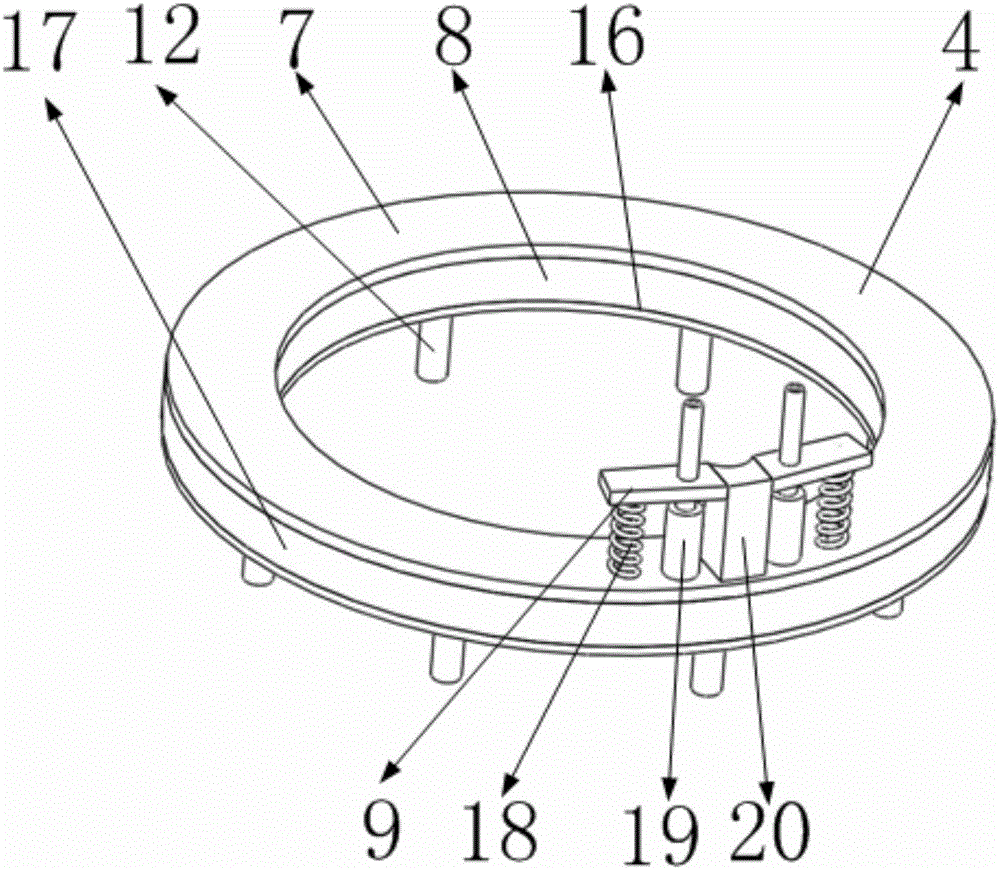

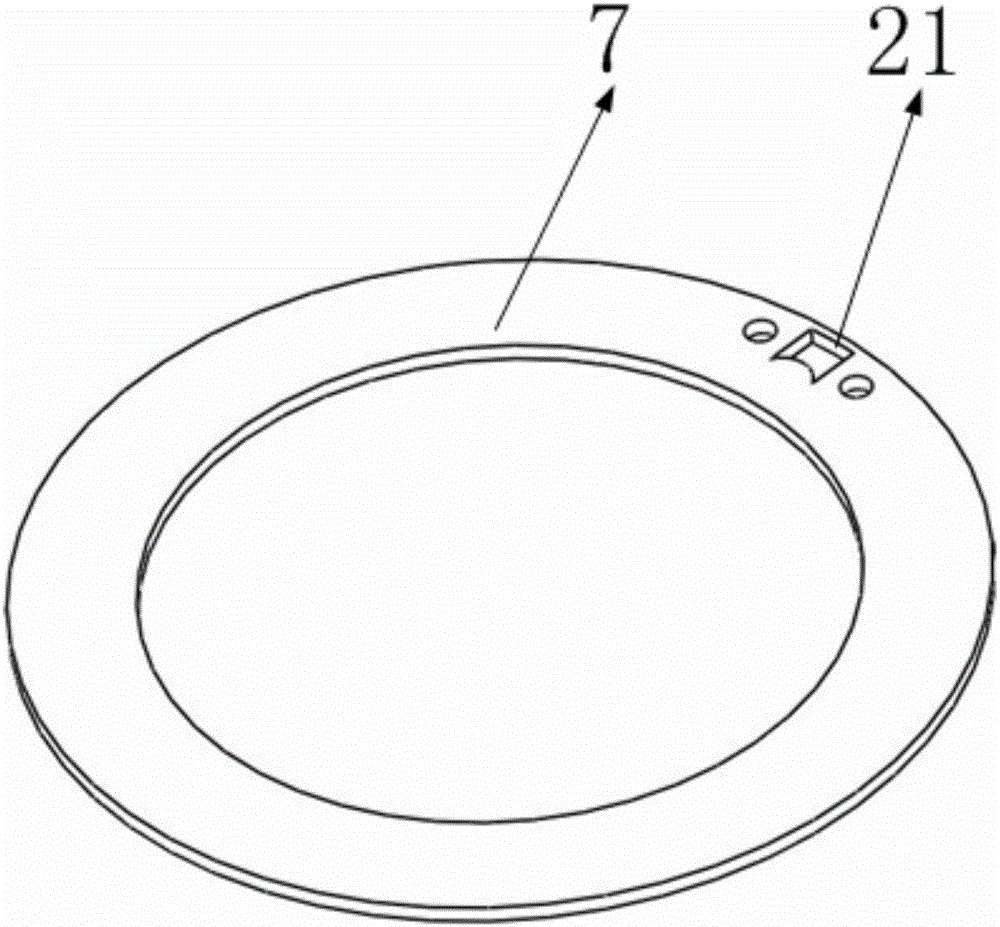

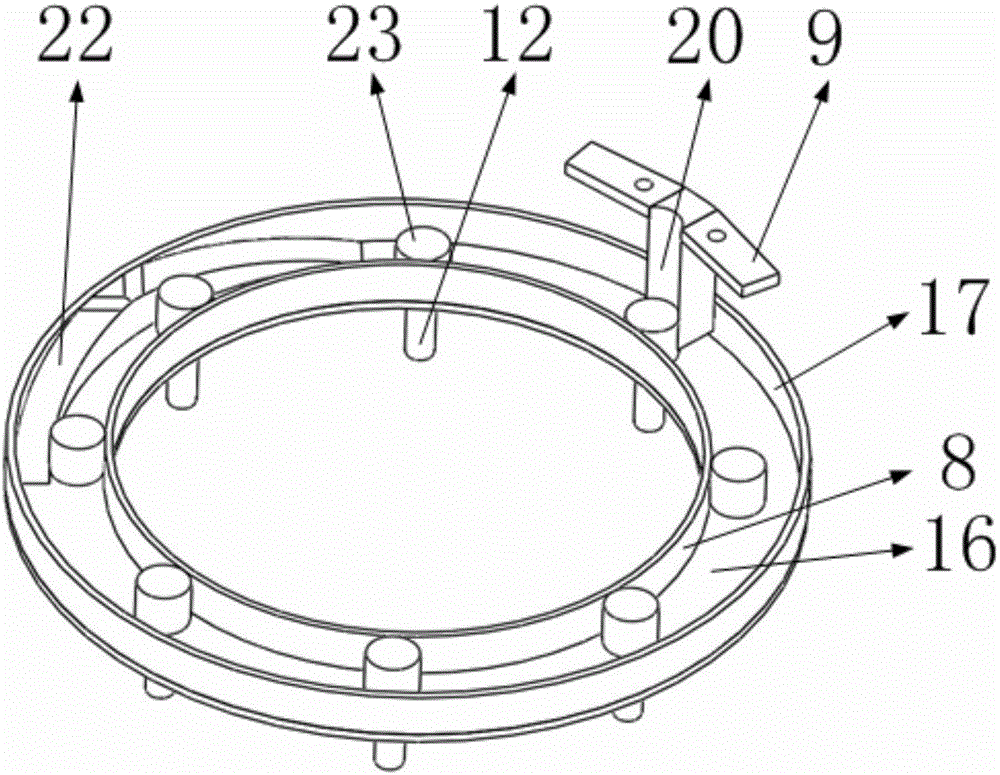

[0028] Such as Figure 7 , 8 As shown, a small pulsation thin air compressor is characterized in that it includes a support column, a base, a motor, a compression mechanism, a first internal tooth, a first external tooth, a second internal tooth, a second external tooth, a first Three inner teeth, third outer teeth, first center teeth, second center teeth, third center teeth, motor shaft, among which Figure 7 As shown, the compression mechanism is installed on the base through three support columns uniformly fixed in the circumferential direction; the motor is installed in the center of the compression mechanism, and the thickness of the motor is the same as that of the compression mechanism; Figure 11 As shown, the diameters of the first central tooth, the second central tooth, and the third central tooth decrease in order, and they are installed on the motor shaft of the motor in sequence, and the first central tooth is closest to the end face of the motor; Figure 9 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com