Power source unit body for ejection, aircraft carrier gas steam ejector and ejection method

A technology of gas steam and power source, applied in the direction of cartridge ammunition, launching/dragging transmission device, ammunition, etc., it can solve the problems of large pressure loss, large forward resistance of piston assembly, impossibility of catapult, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Embodiments of the present invention will be described in detail below with reference to the drawings.

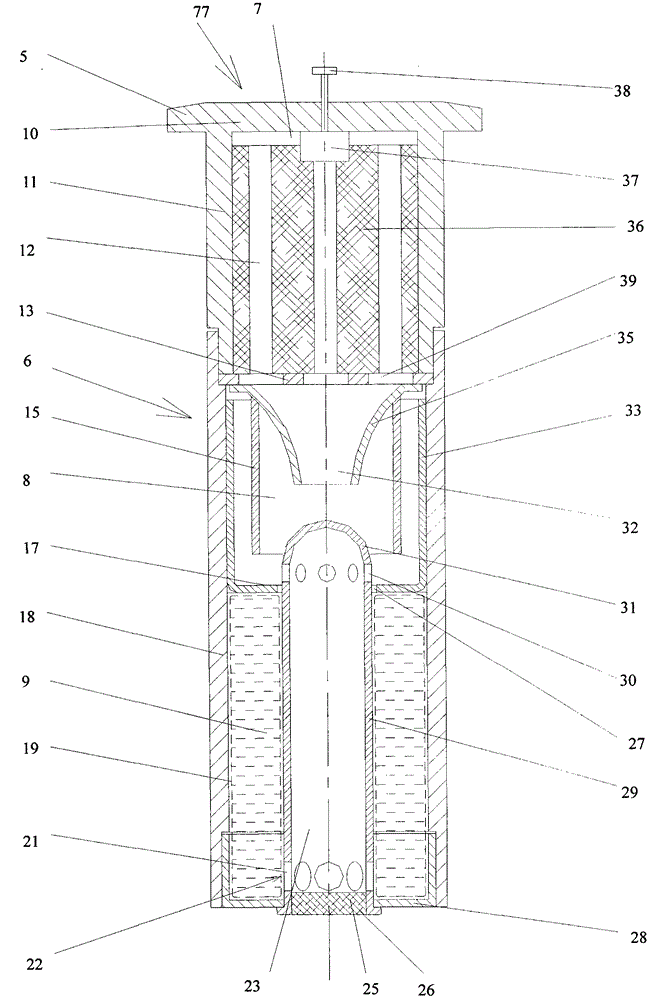

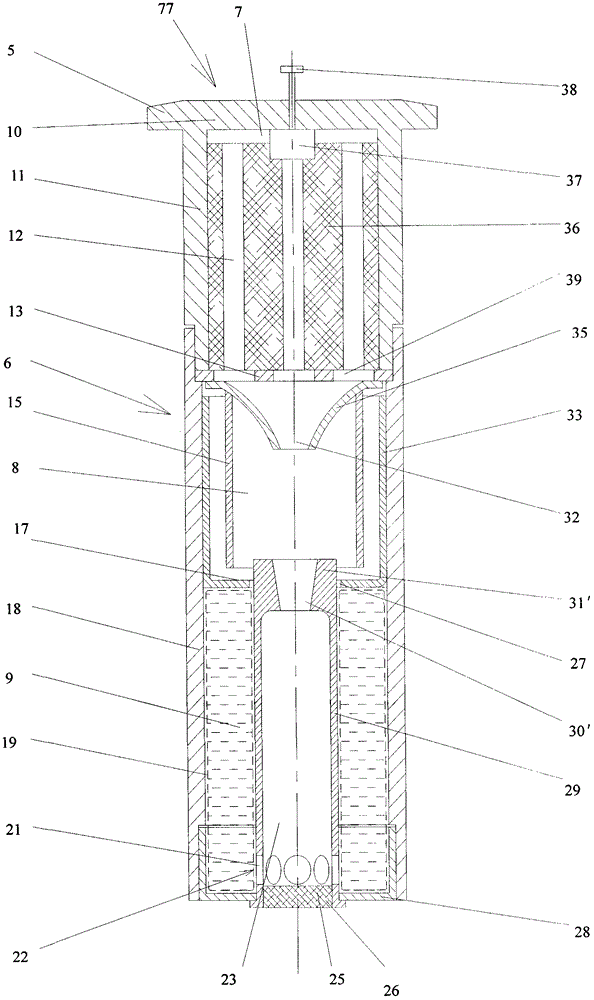

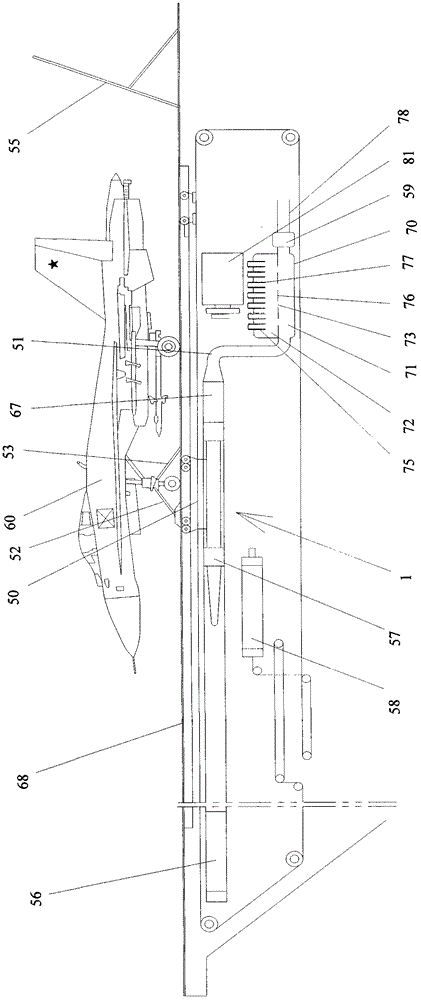

[0050] figure 1 It is the structural representation of gas steam bomb 77 of the present invention. Such as figure 1 As shown, the cartridge case 6 of the gas steam bomb 77 includes a cylinder bottom 11 and a cylinder portion 18, and one end of the cylinder bottom 11 and the cylinder portion 18 is connected as a whole by a screw thread (also can be other ways), and the cylinder bottom 11 has an ejection shell. The bottom edge 5 used is provided with a porous fixed frame 13 inside the cartridge case 6, and the fixed frame 13 is fixed with gunpowder 36 (or called solid propellant), between the gunpowder 36 and the bottom 10 of the bottom 11 of the barrel. An igniter 37 is provided, and an igniter control device 38 is arranged on the outside of the cylinder bottom 10 at a position capable of firing from the outside, and is connected to the igniter 37 through the cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com