A delivery pipeline supply pressurization system for enameled wire production

A technology for conveying pipelines and pressurizing systems, applied in pipeline systems, transportation and packaging, mechanical equipment, etc., can solve the problem that the stability and smoothness of paint liquid cannot be guaranteed, affect the spraying effect of paint liquid, and affect the quality of enameled wires. and other problems, to achieve the effect of convenient and fast mixing, simple structure and stable transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following in conjunction with the accompanying drawings and embodiments of the specification, the specific embodiments of the present invention will be further described in detail:

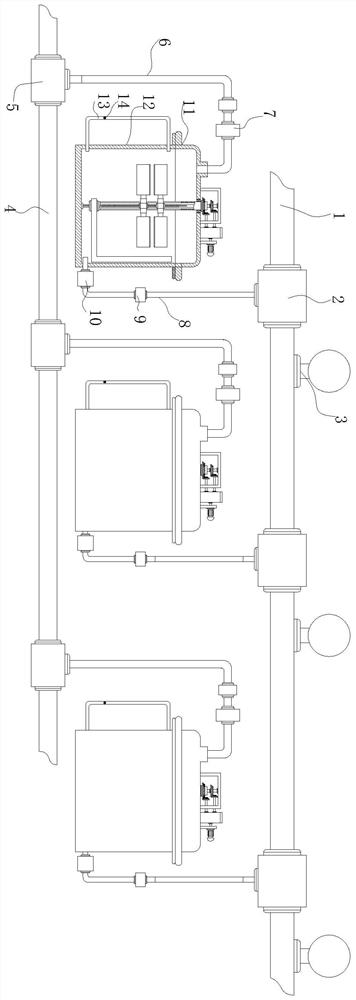

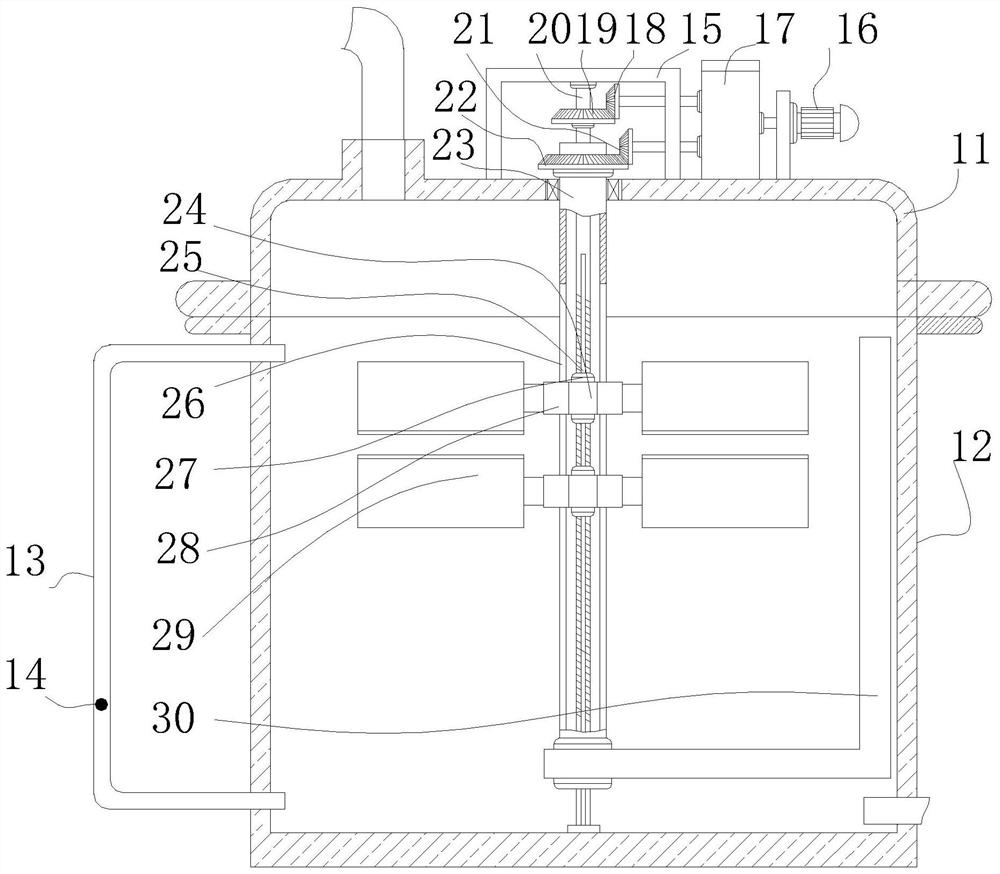

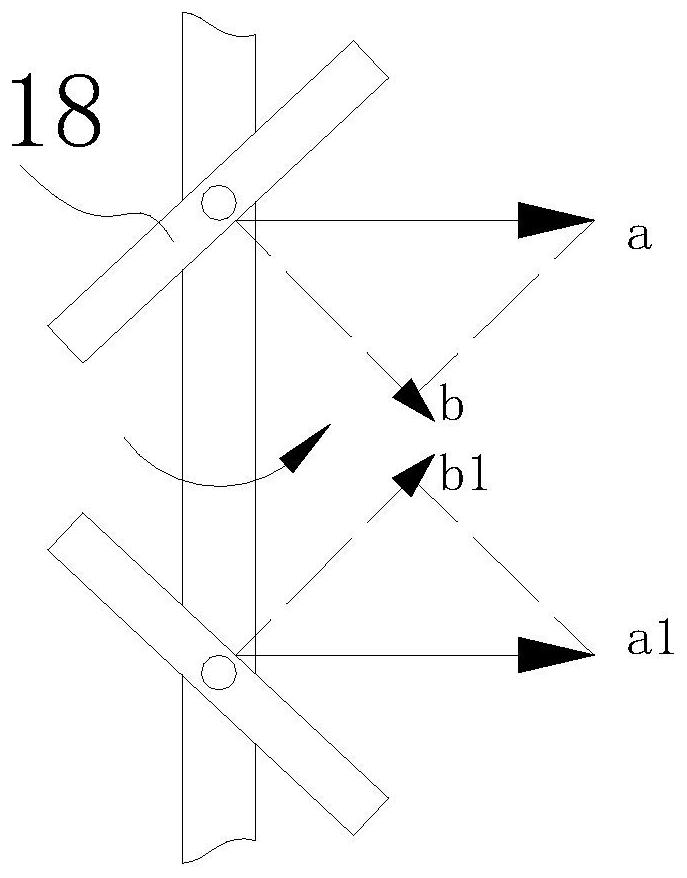

[0023] Reference Figures 1 through 4 A kind of enameled wire production with the conveying pipeline to supply the pressurization system, comprising a main pipe 1 and an equal distance set on the main pipe 1 pressurization unit, each of the pressurized unit comprises a tee joint 2, a manometer 3 and a paint box thereof, the paint box is provided with a stirring device for stirring the paint liquid, the tee joint 2 and the pressure gauge 3 are installed on the main pipe 1, the outlet of the paint tank is connected to an interface of the tee joint 2 through the sub-pipe 8, And the sub-pipe 8 is installed with a conveyor pump 10 and a one-way solenoid valve 9, further comprising a paint system for painting the paint box, the paint system comprises a paint main 4 and an equal distance set on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com