A Novel Concave Flame Stabilizing Gas Stove and Its Application Method

A gas stove and concave cavity technology, applied in the direction of combustion methods, applications, burners, etc., can solve the problems of continuous adjustment of heating temperature, easy occurrence of flame separation and flameout, long ignition delay time, etc., and achieve simple structure and easy The effect of ignition and flame stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

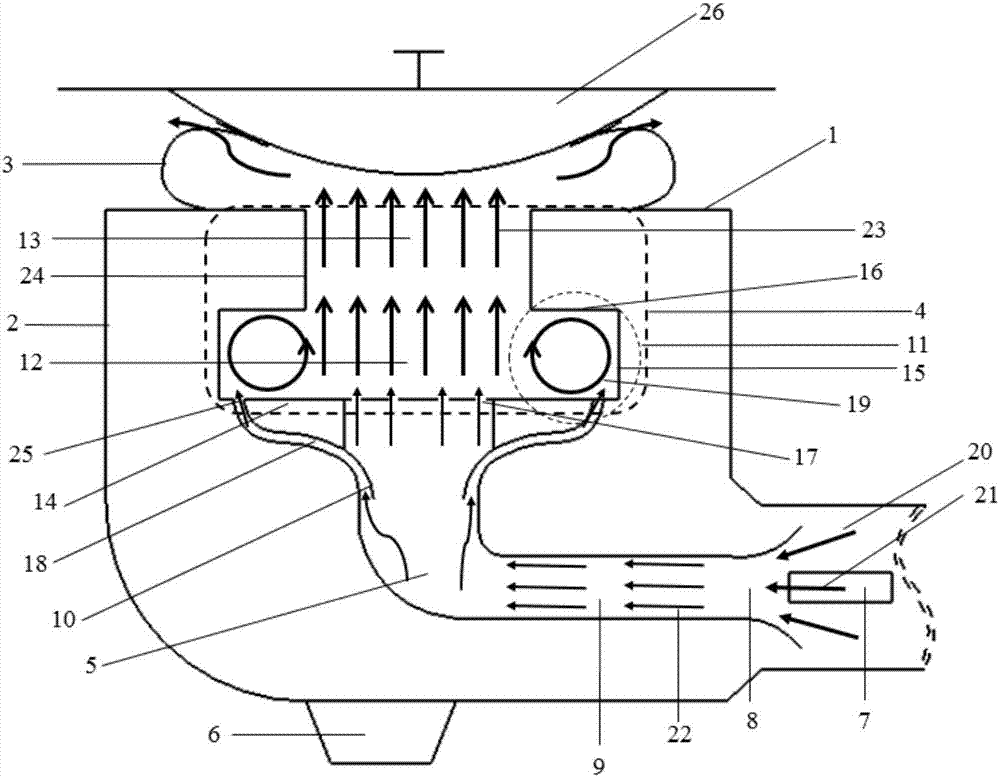

[0016] Please refer to figure 1 As shown, a novel concave cavity flame-stabilizing gas stove 1 of the present invention includes: a housing 2, a pan support 3 located on the housing 2, a burner 4 located in the housing 2 and arranged under the pan support 3 , the burner 5 below the burner 4, the gas mixing section 9 extending from the bottom of the burner 5, the gas nozzle 7 injecting gas into the gas mixing section 9, an electronic lighter (not shown), a gas diverter valve (not shown) icon).

[0017] The burner 4 includes a main combustion zone 12 carried above the middle position of the burner 4, a trapped vortex zone 11 arranged around the periphery of the main combustion zone 12 and communicated with the main combustion zone 12, and a mixing chamber located above the main combustion zone 12. Zone 13; the diameter of the trapped vortex zone 11 is greater than the diameter of the mixing zone 13; that is, the longitudinal section of the trapped vortex zone 11, the main combu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com