Integrated oven

A technology for integrating stoves and cooktops, applied in the field of integrated stoves, can solve problems such as troublesome operation, affecting the filtering effect, etc., and achieve the effect of strengthening the quiet effect, reducing the heat, and improving the quietness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

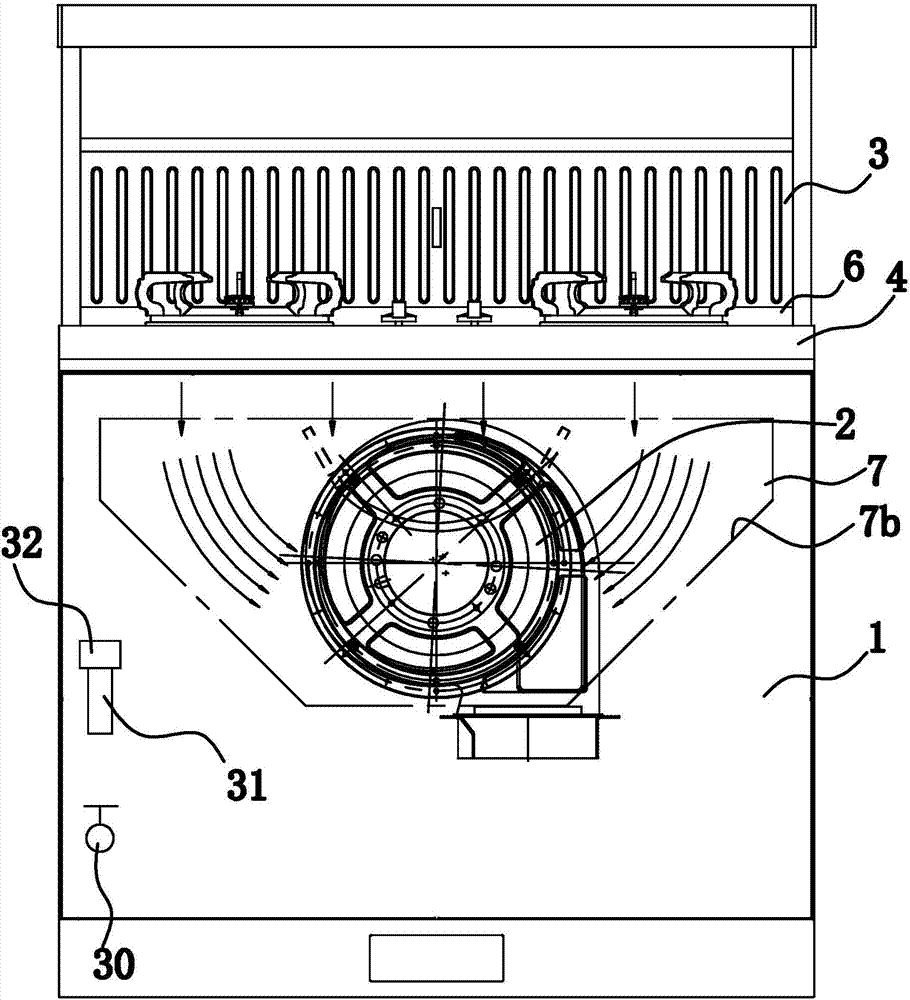

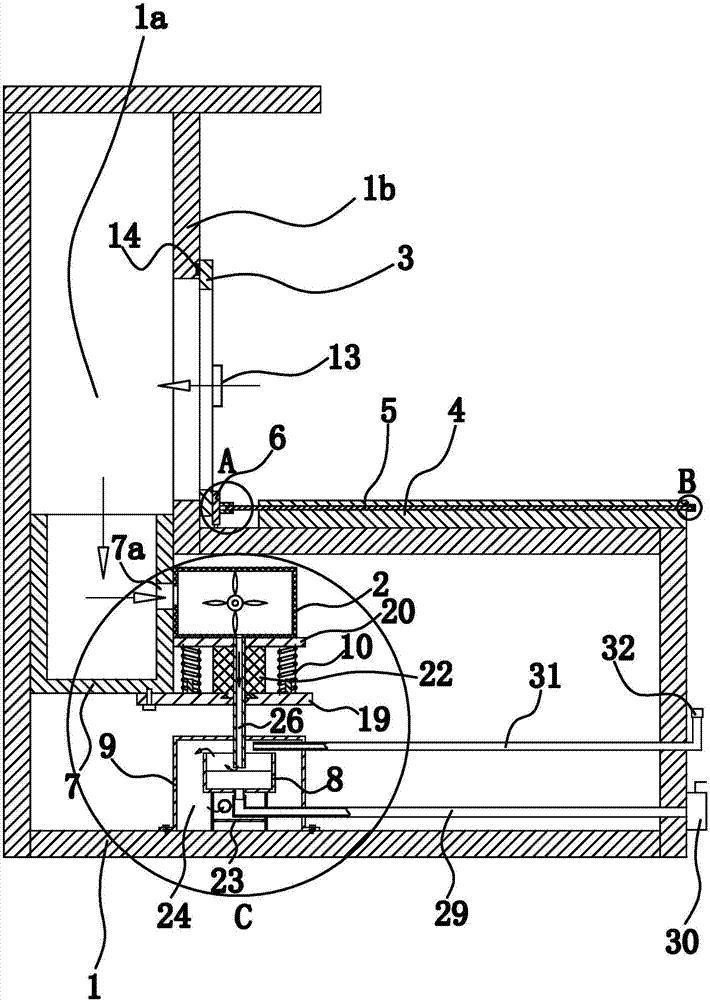

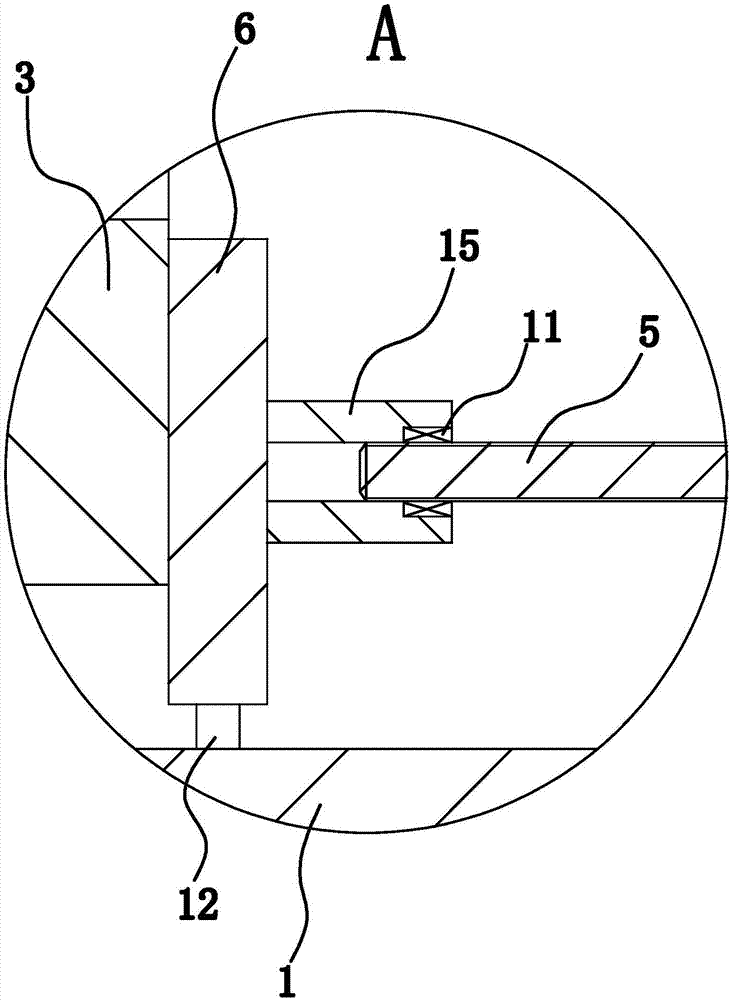

[0055] like Figure 1 to Figure 8 As shown in the figure, the integrated cooker is composed of a shell 1, a fan 2, an oil filter 3, a cooktop 4, a screw 5, a clamping piece 6, a gas gathering tank 7, a water storage bucket 8, a gas gathering barrel 9, a buffer spring 10, etc. . Wherein, the oil filter screen 3 is made of magnetic material, and the magnetic material may be iron, stainless steel, or the like. In this embodiment, the oil filter screen 3 is preferably made of stainless steel.

[0056] like figure 1 and figure 2 As shown, the cooktop 4 is plate-shaped and is arranged on the casing 1 . The cooktop 4 is provided with a gas stove, and the connection between the cooktop 4 and the gas stove is existing, which is not introduced here. The interior of the casing 1 is a cavity, and a smoke exhaust channel 1 a is arranged in the casing 1 , and the smoke exhaust channel 1 a has an outlet and an inlet, wherein the inlet is located on the outer wall of the casing 1 and at...

Embodiment 2

[0074] The structure and principle of the second embodiment are basically the same as those of the first embodiment, except that the concave-convex connection structure includes a circular hole provided on the bottom plate 19 and a cylindrically protruding limit post on the rubber block 22, and The limit post is embedded in the round hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com