Inner balance type pre-stressed anchor cable stress corrosion test system and method

A stress corrosion and test system technology, applied in the direction of applying stable tension/pressure to test material strength, weather resistance/light resistance/corrosion resistance, measuring device, etc., can solve the problem of high cost, randomness, easy leakage, etc. problem, to achieve the effect of simple structure, reasonable design and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention. It should be understood that the embodiments described below are only a part of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained without making creative efforts belong to the protection scope of the present invention.

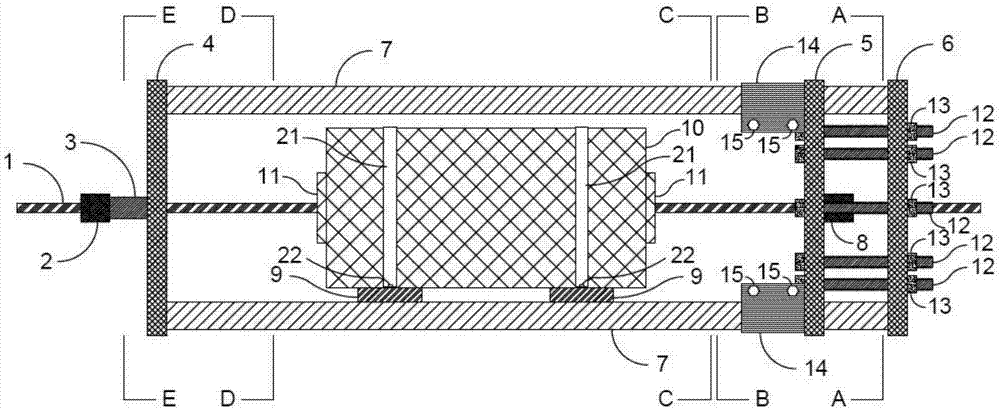

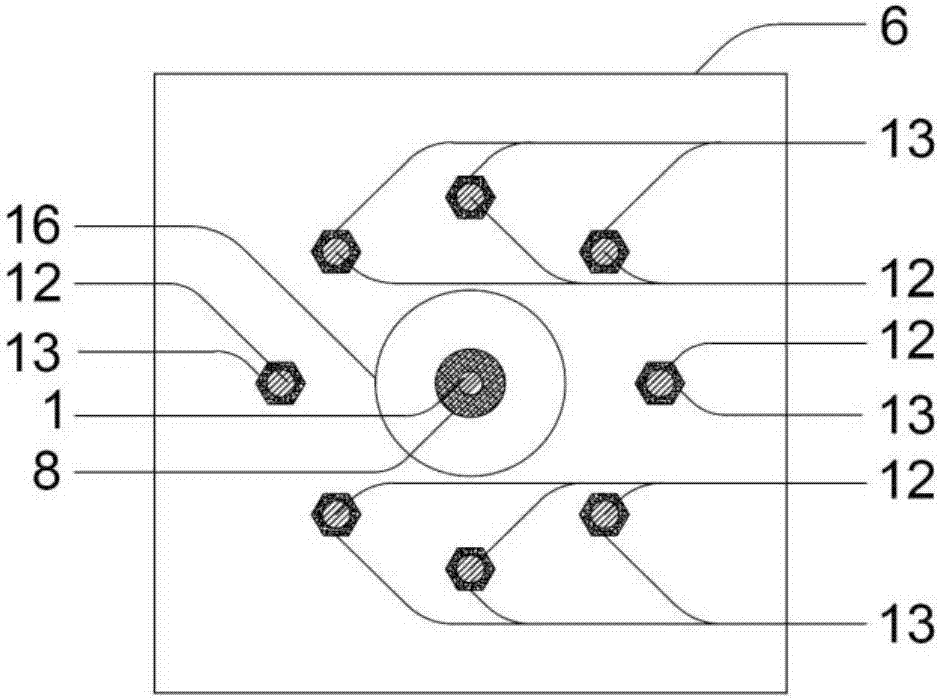

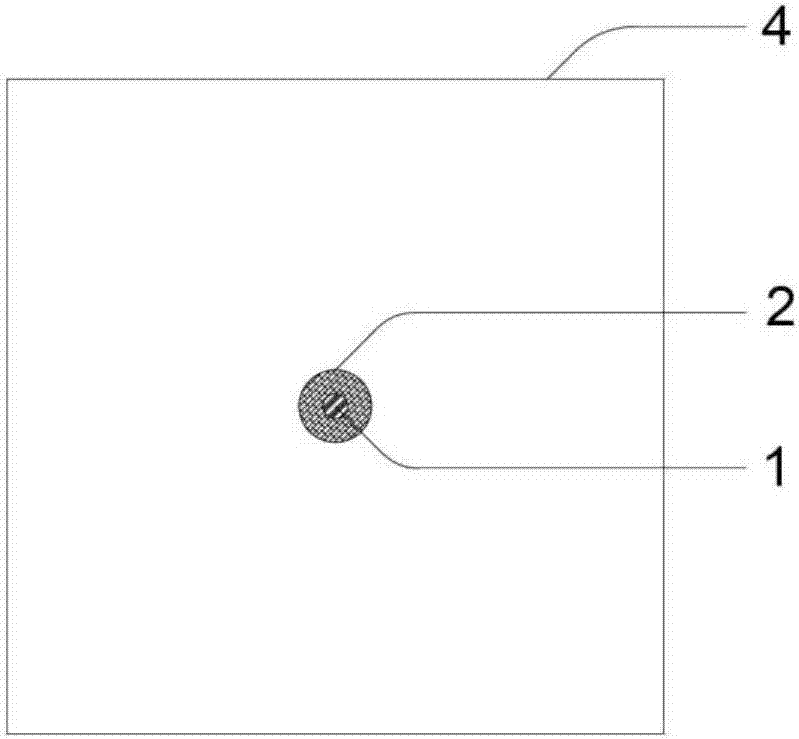

[0031] see Figure 1-9 , in an embodiment of the present invention, an internally balanced prestressed anchor cable stress corrosion test system includes a fixed end supporting steel plate 4, a loading end supporting steel plate 6, a loading movable steel plate 5, a tension structure supporting steel pipe 7, and loading bolts 12, Loading nut 13, loading movable steel plate fixed lock 14, fixed lock bolt 15, fixed lock nut 19, corrosion solution container 10, corrosion solution container...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com