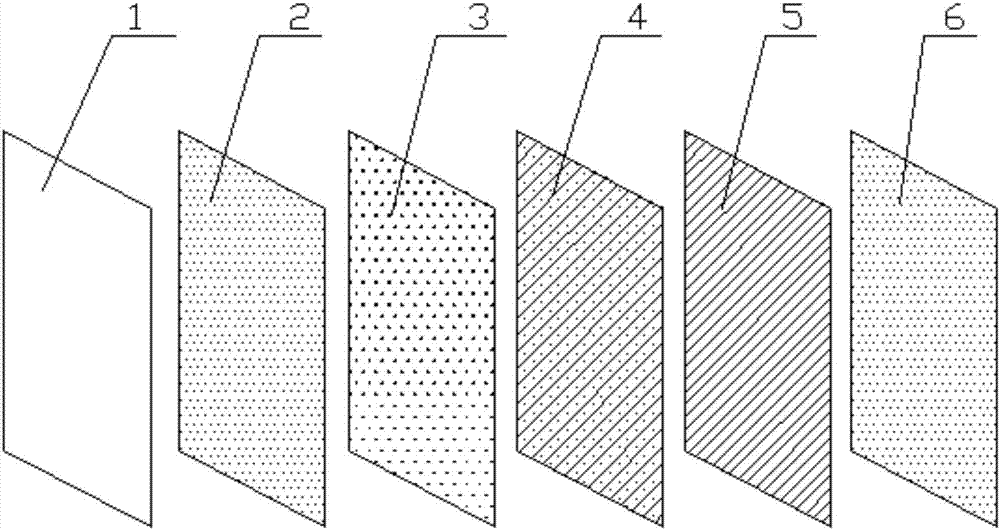

Mimetic touch screen and preparation method thereof

A touch screen and touch layer technology, applied in the field of touch screens, can solve the problems of insufficient display accuracy of the touch screen, insufficient blackness of the display area, and insufficient display accuracy, and achieves mimicking and blackness of the display effect. Strong expressiveness, the effect of increasing the display blackness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

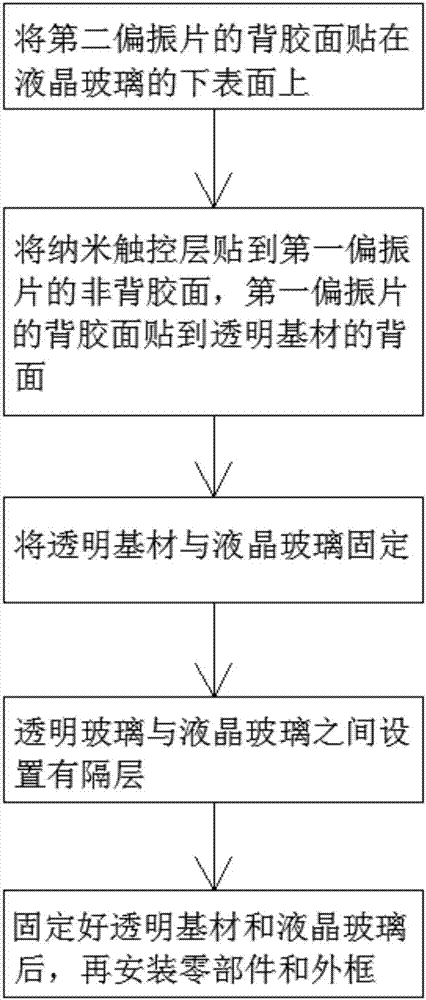

[0026] Such as figure 2 As shown, the present invention also discloses a method for preparing a mimic touch screen, comprising the following steps:

[0027] (1) Paste the adhesive surface of the second polarizer on the lower surface of the liquid crystal glass by laminating instrument or manually;

[0028] (2) paste the nano-touch layer on the non-adhesive surface of the first polarizer; paste the adhesive surface of the first polarizer on the back of the transparent substrate; when pasting the nano-touch layer, manually or by machine To stick the film, the film sticking method is carried out by wet sticking or dry sticking;

[0029] (3) Then fix the transparent substrate and liquid crystal glass, and the transparent substrate and liquid crystal glass are fixed together by foam double-sided adhesive, or fixed by a frame, and the frame material can be selected according to the actual application. Different materials, such as aluminum alloy material;

[0030] (4) In step (3)...

Embodiment 1

[0035] Use this preparation method to prepare a 22-inch touch screen, and its preparation method is as follows:

[0036] (1) Cut out the second polarizer of 22 inches, place it on the bonding machine, and paste the second polarizer on the lower surface of the 22-inch liquid crystal glass by the machine;

[0037] (2) Paste the first polarizer of the same size on the lower surface of the 22-inch transparent substrate by a bonding machine, and then paste the 22-inch nano-touch layer on the outside of the first polarizer in turn;

[0038] (3) Fix the aluminum alloy frame around the liquid crystal glass, and finally fix the tempered glass with the first polarizer and the nano-touch layer on the liquid crystal glass, because the aluminum alloy frame causes the gap between the transparent substrate and the liquid crystal screen There is a 1mm thick distance, which is the air layer, and finally fix other parts.

Embodiment 2

[0040] (1) Spray the cleaning solution diluted 20 times with water on the lower surface of the 43-inch liquid crystal glass, and stick the second polarizer after aligning the position, scrape off the excess cleaning solution by hand with a scraper, and stick the polarizer after natural drying joined to the glass;

[0041] (2) stick a 3mm thick transparent interlayer on the upper surface of 43 cun liquid crystal glass, present embodiment selects transparent PMMA plate (being commonly called as plexiglass);

[0042] (2) Spray the diluted washing liquid on the lower surface of the transparent substrate, paste the first polarizer, scrape off the excess washing liquid with a scraper manually, and spray the diluted washing liquid on the outside of the first polarizer after it dries. After the final washing liquid, paste the nano-touch layer, scrape off the excess washing liquid with a scraper, and dry the transparent substrate with the nano-touch layer and the first polarizer;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com