3D connected fan-out type packaging structure and process method therefor

A packaging structure, fan-out technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems that the number of interconnected I/Os cannot be increased, and the number of metal pillars on the substrate is difficult to further increase, so as to increase complexity, The effect of fine spacing and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

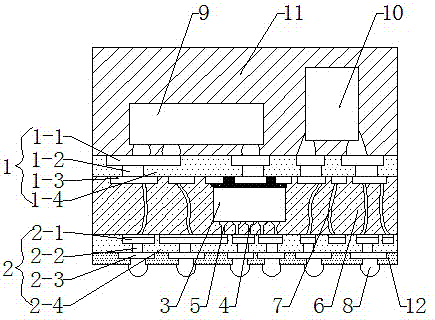

[0048] see figure 1 , a 3D-connected fan-out packaging structure in this embodiment, which includes a circuit layer 1, and the circuit layer 1 includes a first circuit layer 1-1, a second circuit layer 1-3, and the first circuit layer The layer 1-1 and the second circuit layer 1-3 are electrically connected through the first metal pillar 1-2, and the first insulating material 1 is surrounded by the first circuit layer 1-1 and the first metal pillar 1-2 -4, the back of the circuit layer 1 is provided with a chip 3, the front of the chip 3 is provided with metal balls 4 and first bonding wires 5, the front of the chip 3 is provided with a rewiring circuit layer 2, and the chip 3 and The redistribution circuit layers 2 are connected through the metal ball post 4 and the first bonding wire 5, and the circuit layer 1 and the redistribution circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com