L-section type concentrating photovoltaic battery chip

A concentrating photovoltaic and battery technology, applied in the field of solar photovoltaic power generation, can solve the problem of reducing the effective light-receiving area of the concentrating photovoltaic cell chip, wasting the substrate material of the concentrating photovoltaic cell base layer, reducing the power generation efficiency of the concentrating photovoltaic system, etc. problems, to achieve the effect of no reduction in power generation efficiency, reduction of production costs, and reduction of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

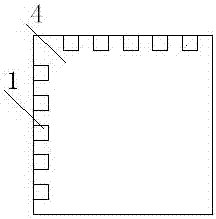

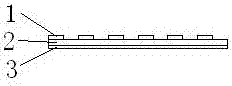

[0015] A kind of L segment type concentrator photovoltaic cell chip, such as Figure 1~2 As shown, it includes a negative electrode segment layer 1, a concentrating photovoltaic cell base material layer 2, a positive electrode layer 3 and an effective area 4. One side of the concentrating photovoltaic cell base material layer 2 is covered with a negative electrode segment layer 1, and the other side is covered with The upper positive electrode layer 3, the part other than the negative electrode segment layer 1 is an effective area 4, the negative electrode segment layer 1 is a flat L-shaped shape, two of the negative electrode segment layer and the concentrating photovoltaic cell substrate layer The two adjacent end faces are completely overlapped, so that the substrate layer of the concentrating photovoltaic cell is fully utilized, thereby achieving the purpose of sav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com