Commercial furnace remote monitoring system

A remote monitoring system and stove technology, applied in transmission systems, household appliances, household stoves/stoves, etc., can solve problems such as troubleshooting, low gas utilization, and inability to sense and cut off in time, so as to accurately respond to emergencies Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: User Control

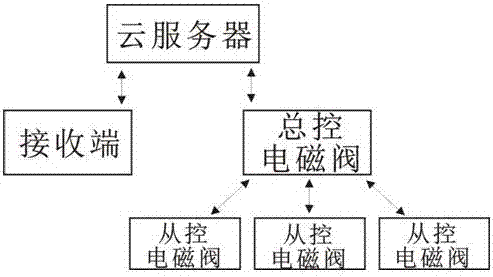

[0024] The sensor is responsible for the monitoring of fuel delivery flow and stove failure detection, and uploads the corresponding data to the cloud server in real time through the information acquisition board. The cloud server performs digital calculations based on the original flow data stored by itself, and feeds back the results to the receiving end at regular intervals , the receiving end can directly send a control command to the cloud server according to its own adjustment needs, and the cloud server will judge whether the control command is a white command module after the identity recognition is successful, and if it is a white command module, it will directly issue a control command to the master control solenoid valve Command, and then the command is transmitted from the master control solenoid valve to the slave control solenoid valve to realize the direct control of the receiving end on its own fuel. If it is an inquiry command, ...

Embodiment 2

[0025] Embodiment 2: Supplier or manager control

[0026] The sensor is responsible for the monitoring of fuel delivery flow and stove failure detection, and uploads the corresponding data to the cloud server in real time through the information acquisition board. Feedback, the supplier performs fuel delivery control according to the feedback, and directly performs the control operation of the master control solenoid valve on the cloud server. At this time, the control is regarded as a white command module, and the cloud server issues commands to the master control solenoid valve, and then the master control The solenoid valve transmits commands to the slave control solenoid valve to realize the switching of the slave control solenoid valve, that is, to realize the control of fuel delivery at the supply end.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com