Processing method of tea leaves

A processing method and tea technology, which is applied in the field of tea processing, can solve the problems of unstable tea quality and high defective rate, and achieve the effects of low defective rate, stable quality and good color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

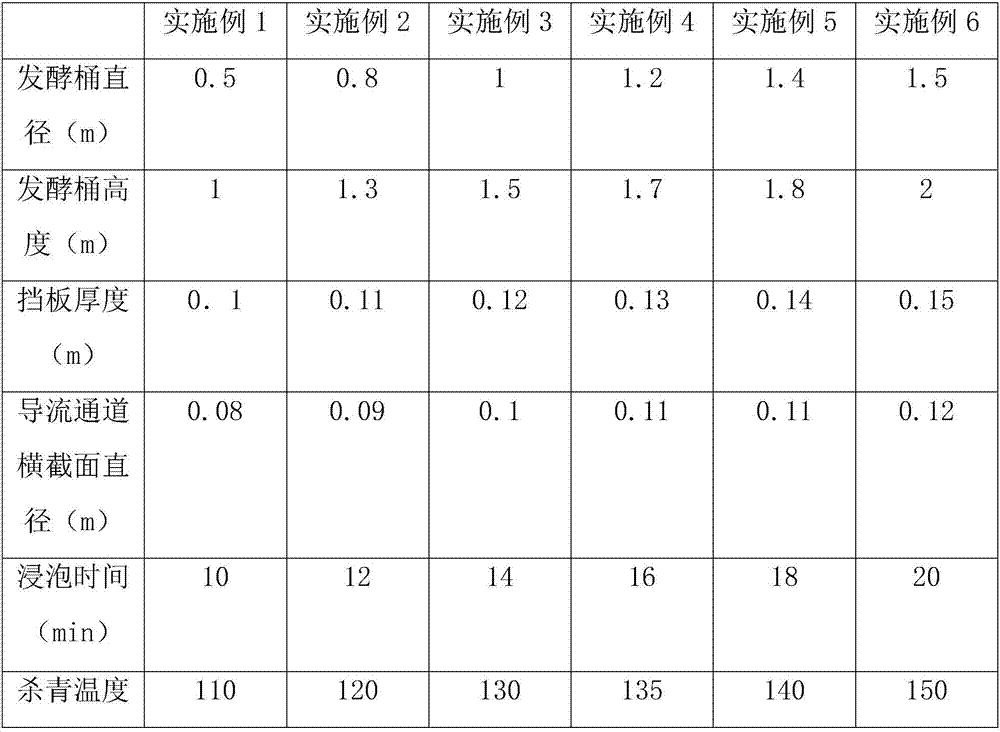

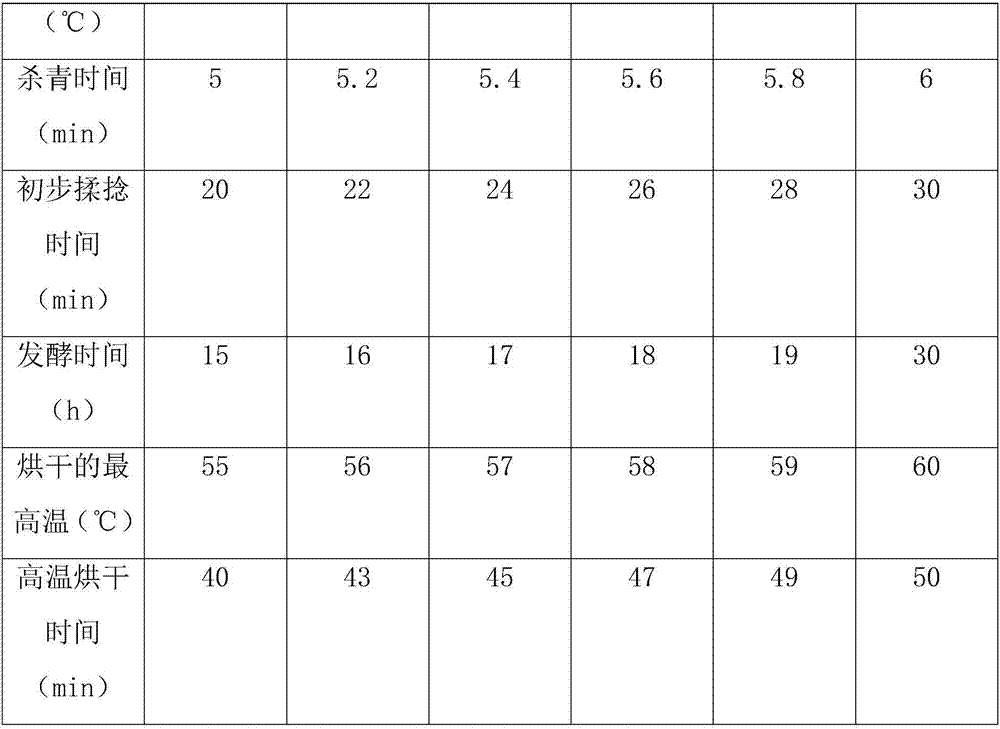

[0023] The present invention will be described in further detail below by means of specific embodiments:

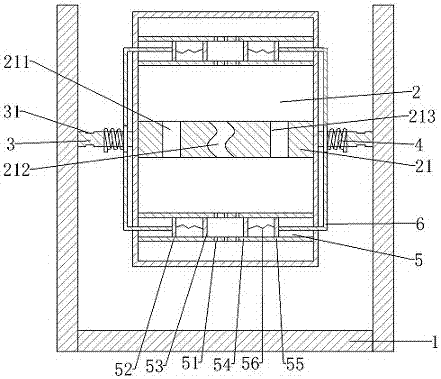

[0024] The reference signs in the drawings of the description include: frame 1, fermenter 2, baffle plate 21, first guide channel 211, second guide channel 212, third guide channel 213, rotating shaft 3, annular groove 31 , torsion spring 4, air bag 5, through hole 51, the first slide plate 52, the second slide plate 53, the third slide plate 54, the fourth slide plate 55, elastic member 56, push rod 6.

[0025] The processing method of tealeaves of the present invention, adopts following tea pile fermenting device to carry out tealeaves pile fermentation, as figure 1 As shown, it includes a frame 1, and the frame 1 includes a cross bar and a longitudinal bar positioned at both ends of the cross bar. A fermenter 2 is arranged between the two longitudinal bars, and the left and right sides of the fermenter 2 are connected to each other by a rotating shaft 3 and The longit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com