Stone material efficient crushing equipment for rare earth processing

A stone and high-efficiency technology, which is applied in the field of high-efficiency crushing equipment for rare earth processing stones, can solve the problems of large crushing volume, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

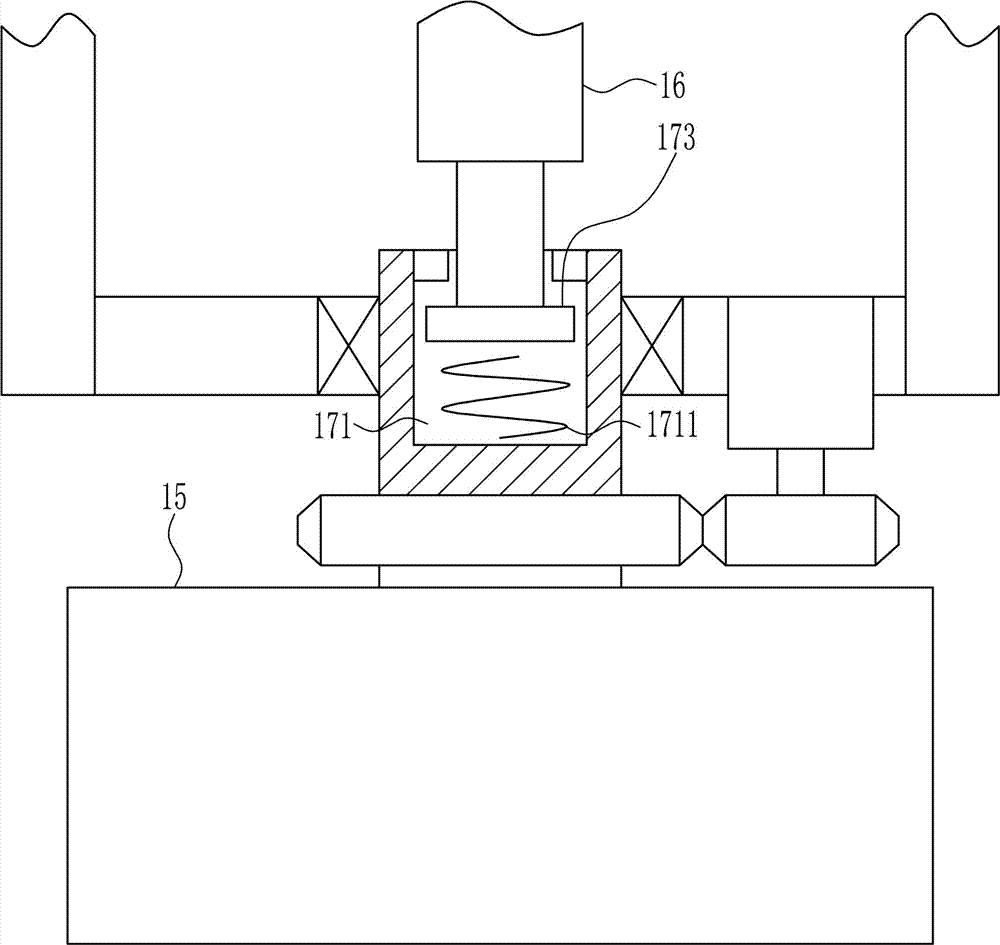

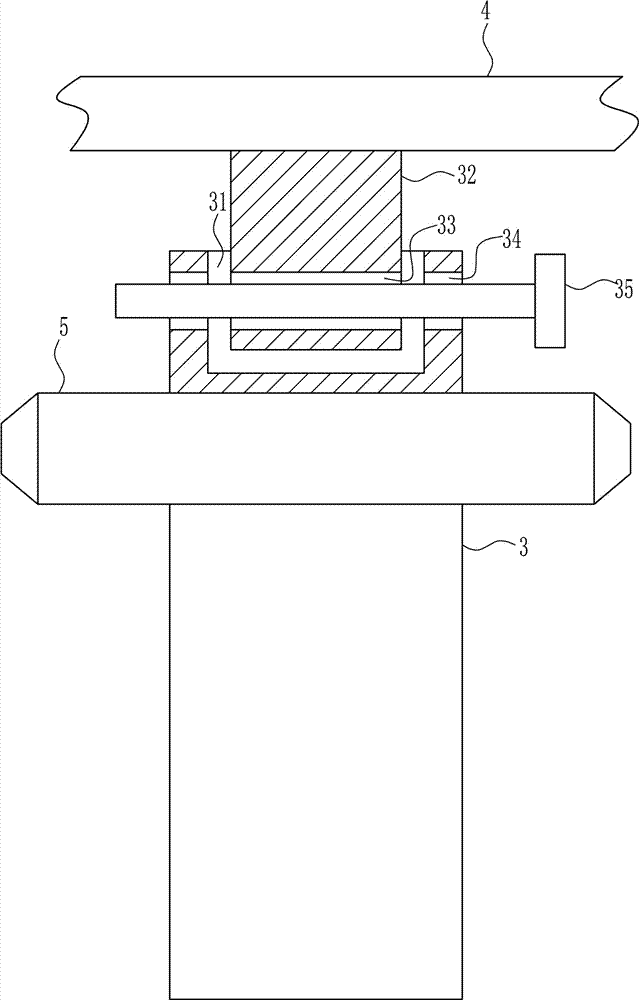

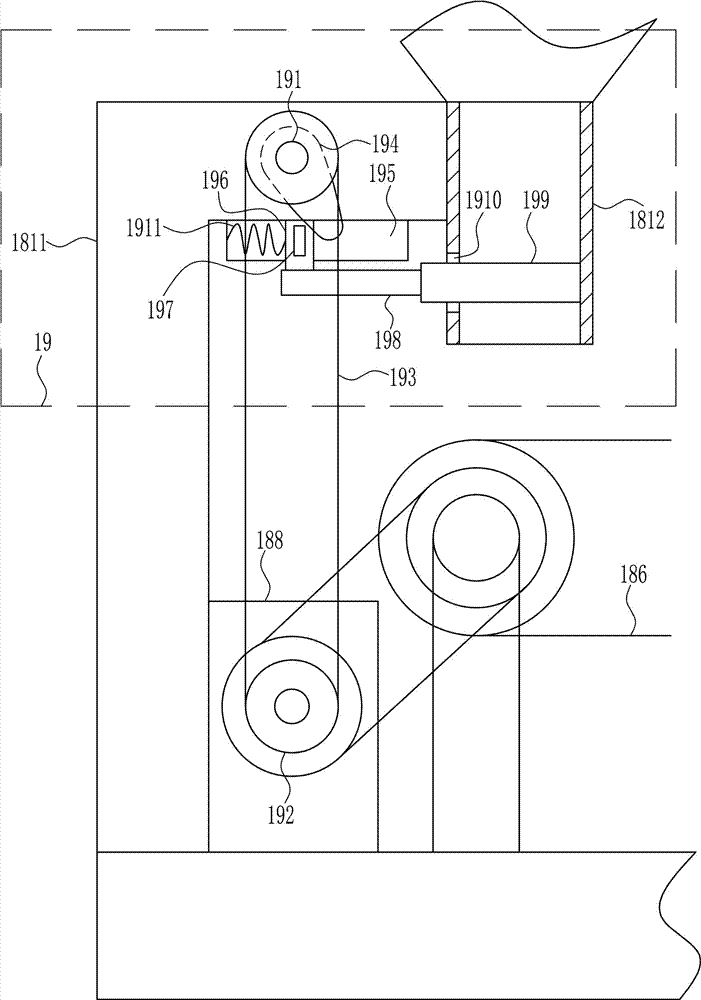

[0038] A high-efficiency crushing equipment for rare earth processing stones, such as Figure 1-8 As shown, it includes a bottom plate 1, a first bearing seat 2, a first rotating rod 3, a crushing box 4, a first gear 5, a first motor 6, a second gear 7, a support plate 8, a support rod 9, and a guide rail 10 , guide sleeve 11, connecting rod 12, connecting block 13, fixed block 14, crushing weight 15 and cylinder 16, the middle part of the bottom plate 1 is installed with the first bearing seat 2 by means of bolt connection, and the first bearing seat 2 passes through The first rotating rod 3 is connected in the way of interference connection, the upper end of the first rotating rod 3 is installed with a crushing box 4 by means of welding, the upper side of the first rotating rod 3 is installed with a first gear 5 by means of bolt connection, and the bottom plate 1. The first motor 6 is installed on the upper right side through bolt connection. The first motor 6 is located on ...

Embodiment 2

[0040] A high-efficiency crushing equipment for rare earth processing stones, such as Figure 1-8 As shown, it includes a bottom plate 1, a first bearing seat 2, a first rotating rod 3, a crushing box 4, a first gear 5, a first motor 6, a second gear 7, a support plate 8, a support rod 9, and a guide rail 10 , guide sleeve 11, connecting rod 12, connecting block 13, fixed block 14, crushing weight 15 and cylinder 16, the middle part of the bottom plate 1 is installed with the first bearing seat 2 by means of bolt connection, and the first bearing seat 2 passes through The first rotating rod 3 is connected in the way of interference connection, the upper end of the first rotating rod 3 is installed with a crushing box 4 by means of welding, the upper side of the first rotating rod 3 is installed with a first gear 5 by means of bolt connection, and the bottom plate 1. The first motor 6 is installed on the upper right side through bolt connection. The first motor 6 is located on ...

Embodiment 3

[0043] A high-efficiency crushing equipment for rare earth processing stones, such as Figure 1-8As shown, it includes a bottom plate 1, a first bearing seat 2, a first rotating rod 3, a crushing box 4, a first gear 5, a first motor 6, a second gear 7, a support plate 8, a support rod 9, and a guide rail 10 , guide sleeve 11, connecting rod 12, connecting block 13, fixed block 14, crushing weight 15 and cylinder 16, the middle part of the bottom plate 1 is installed with the first bearing seat 2 by means of bolt connection, and the first bearing seat 2 passes through The first rotating rod 3 is connected in the way of interference connection, the upper end of the first rotating rod 3 is installed with a crushing box 4 by means of welding, the upper side of the first rotating rod 3 is installed with a first gear 5 by means of bolt connection, and the bottom plate 1. The first motor 6 is installed on the upper right side through bolt connection. The first motor 6 is located on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com