Welding technology for valve body circumferential weld

A welding process and valve body technology, applied in the field of submerged arc welding, can solve problems such as difficult manufacturing and difficult repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

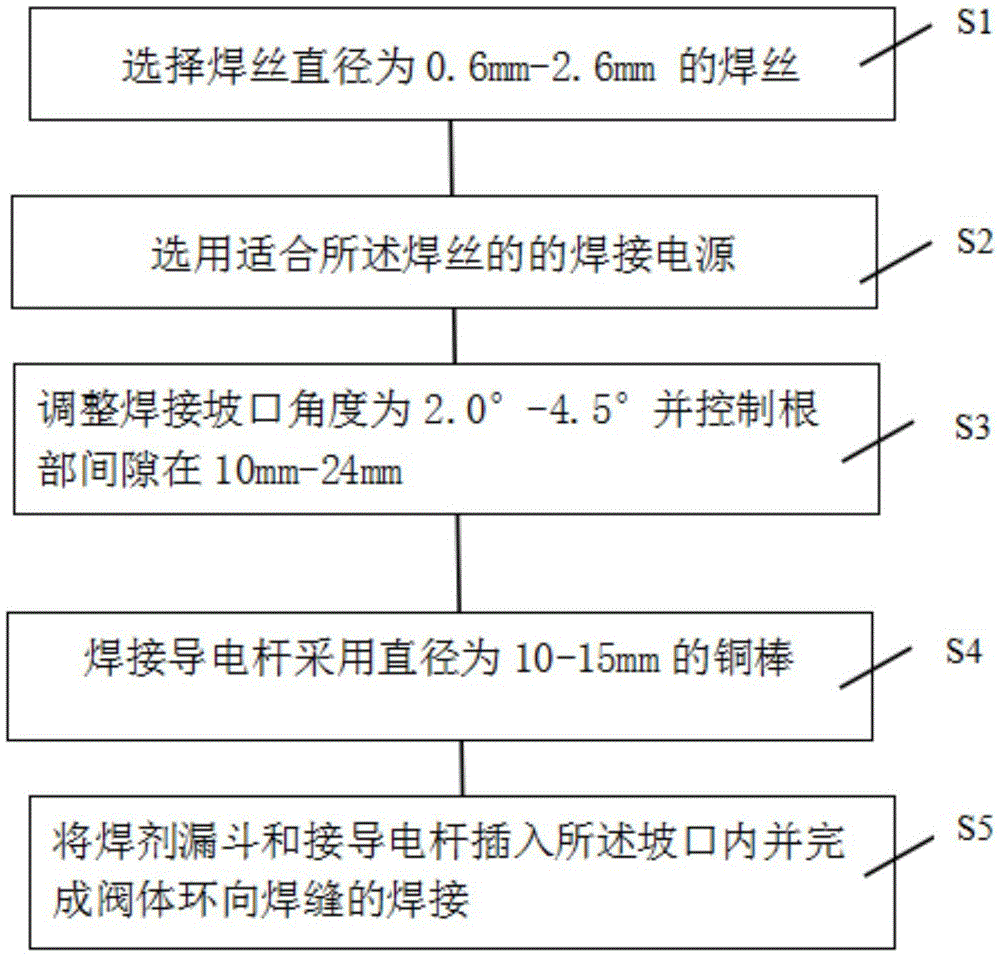

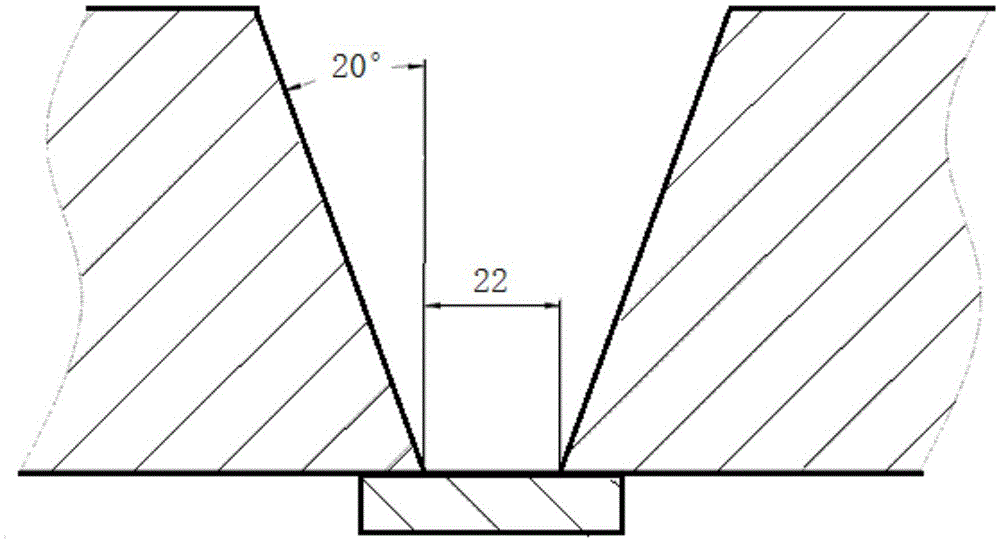

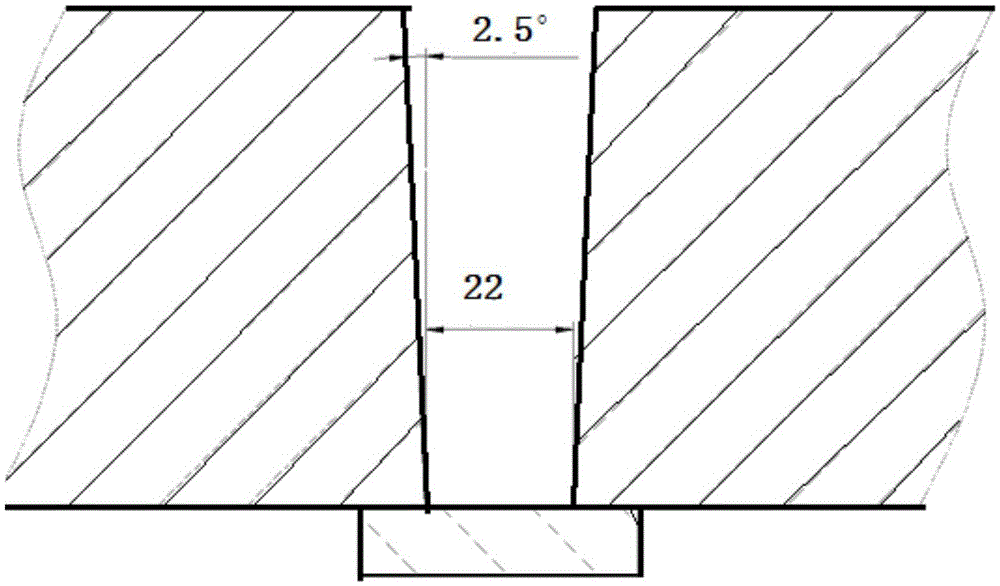

[0041] refer to figure 1 As shown, the welding process of a valve body circumferential weld seam provided by the present invention is specifically one A thin wire, narrow gap groove valve body circumferential submerged arc welding process, comprising the following steps: Step S1: Select welding wire with a diameter of 0.6mm-2.6mm, while ordinary submerged arc welding and narrow gap submerged arc welding The diameter of the welding wire is generally ≥Φ4.0mm, preferably Φ1.6mm in the present invention, the purpose of which is to reduce the heat input per unit length of the circumferential weld. Step S2: Select a welding power source suitable for the welding wire described above, and select a Lincoln (DC600) welding power source suitable for small wires with a duty cycle of 100% to ensure the stability of the welding arc under the condition of continuous welding with small currents combustion. Step S3: Adjust the welding groove angle to 2.0°-4.5° and control the root gap to 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com