Polyethylene-based nanometer composite and preparation method thereof

A nano-composite material and polyethylene-based technology, applied in the field of composite materials and dielectrics, to achieve the effects of compact crystal structure, good resistance to corona corrosion, and high AC breakdown field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

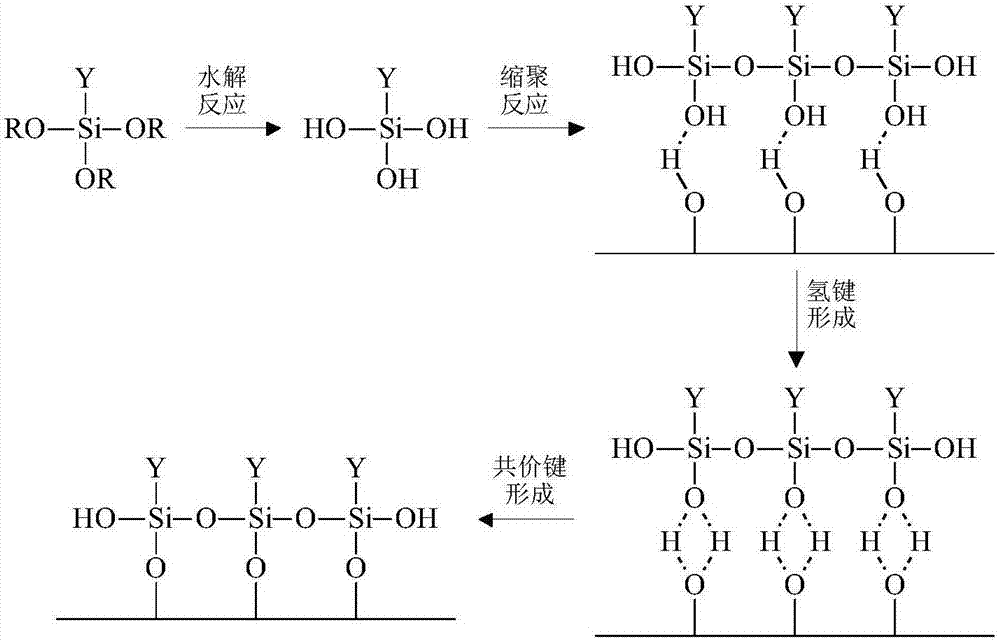

Method used

Image

Examples

Embodiment 1

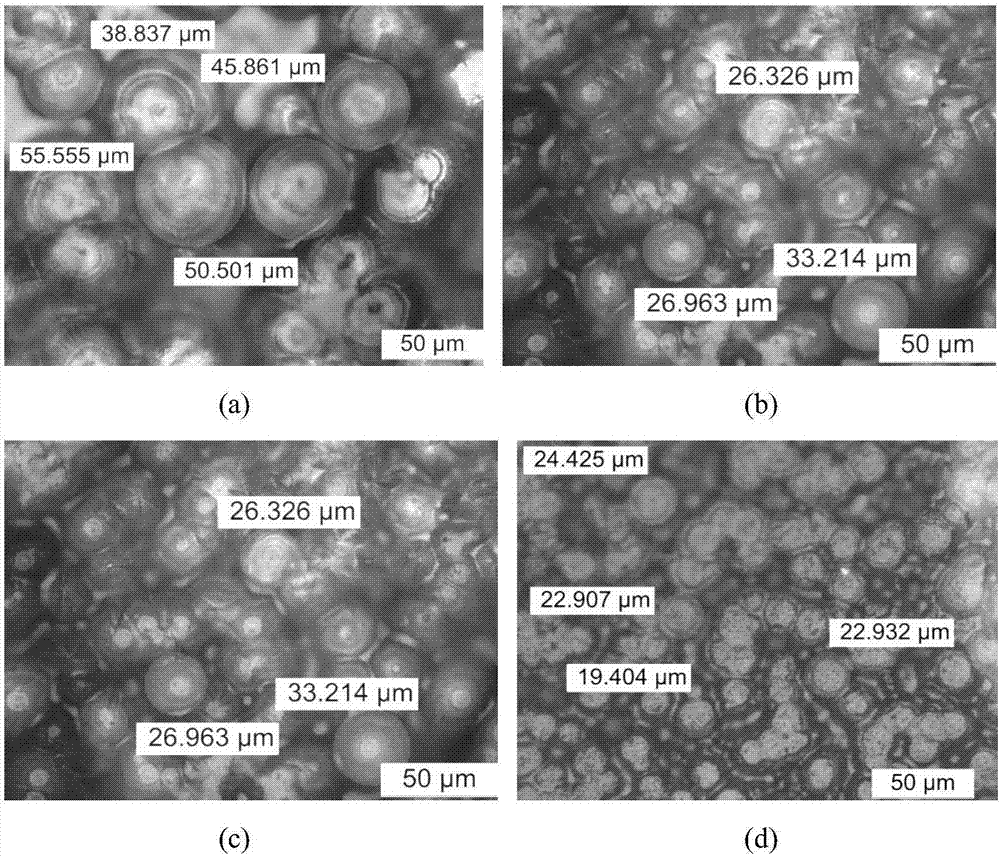

[0037] Take low-density polyethylene 98.7wt% by weight percentage, nano-zinc oxide powder 1wt% after modification, antioxidant 0.3wt%, then it is mixed and joined in the open type rubber mixing machine and carries out melt blending, in mixing During the process, it is necessary to ensure that the room and the two rollers of the mill are clean and free of dust, and the composite material film on the roller is shoveled off with a spatula and put into the gap between the rollers to provide sufficient shearing force. After repeated 20 minutes, the obtained desired polyethylene-based nanocomposites. The temperature of the two rollers is 120° C., and the rotation speed is 40 r / min. Then put the bulk composite material into the required test mold, and use a flat vulcanizer to press and shape it. Among them, the temperature of the flat vulcanizer is 120°C, the pressure starts from 0, increases at a rate of 5MPa / time, and reaches 15MPa, and keeps at each pressure for 5min. Afterwards...

Embodiment 2

[0039] Take low-density polyethylene 96.7wt% by weight percentage, nano zinc oxide powder 3wt% after modification, antioxidant 0.3wt%, then it is mixed and joined in the open rubber mixing machine and carries out melt blending, in mixing During the process, it is necessary to ensure that the room and the two rollers of the mill are clean and free of dust, and the composite material film on the roller is shoveled off with a spatula and put into the gap between the rollers to provide sufficient shearing force. After repeated 20 minutes, the obtained desired polyethylene-based nanocomposites. The temperature of the two rollers is 120° C., and the rotation speed is 40 r / min. Then put the bulk composite material into the required test mold, and use a flat vulcanizer to press and shape it. Among them, the temperature of the flat vulcanizer is 120°C, the pressure starts from 0, increases at a rate of 5MPa / time, and reaches 15MPa, and keeps at each pressure for 5min. Afterwards, the...

Embodiment 3

[0041] Take low-density polyethylene 94.7wt% by weight percentage, nano zinc oxide powder 5wt% after modification, antioxidant 0.3wt%, then it is mixed and joined in the open type rubber mixing machine and carries out melt blending, in mixing During the process, it is necessary to ensure that the room and the two rollers of the mill are clean and free of dust, and the composite material film on the roller is shoveled off with a spatula and put into the gap between the rollers to provide sufficient shearing force. After repeated 20 minutes, the obtained desired polyethylene-based nanocomposites. The temperature of the two rollers is 120° C., and the rotation speed is 40 r / min. Then put the bulk composite material into the required test mold, and use a flat vulcanizer to press and shape it. Among them, the temperature of the flat vulcanizer is 120°C, the pressure starts from 0, increases at a rate of 5MPa / time, and reaches 15MPa, and keeps at each pressure for 5min. Afterwards...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com