A drainage defoaming system and method for thermal nuclear power plants

A nuclear power plant and defoaming technology, which is applied in water conservancy projects, water conservancy engineering equipment, sea area engineering, etc., can solve the problems of serious foam problems, foam overflowing siphon wells, polluting plant areas, etc., and achieves strong adaptability, simple structure, and easy operation. The effect of low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

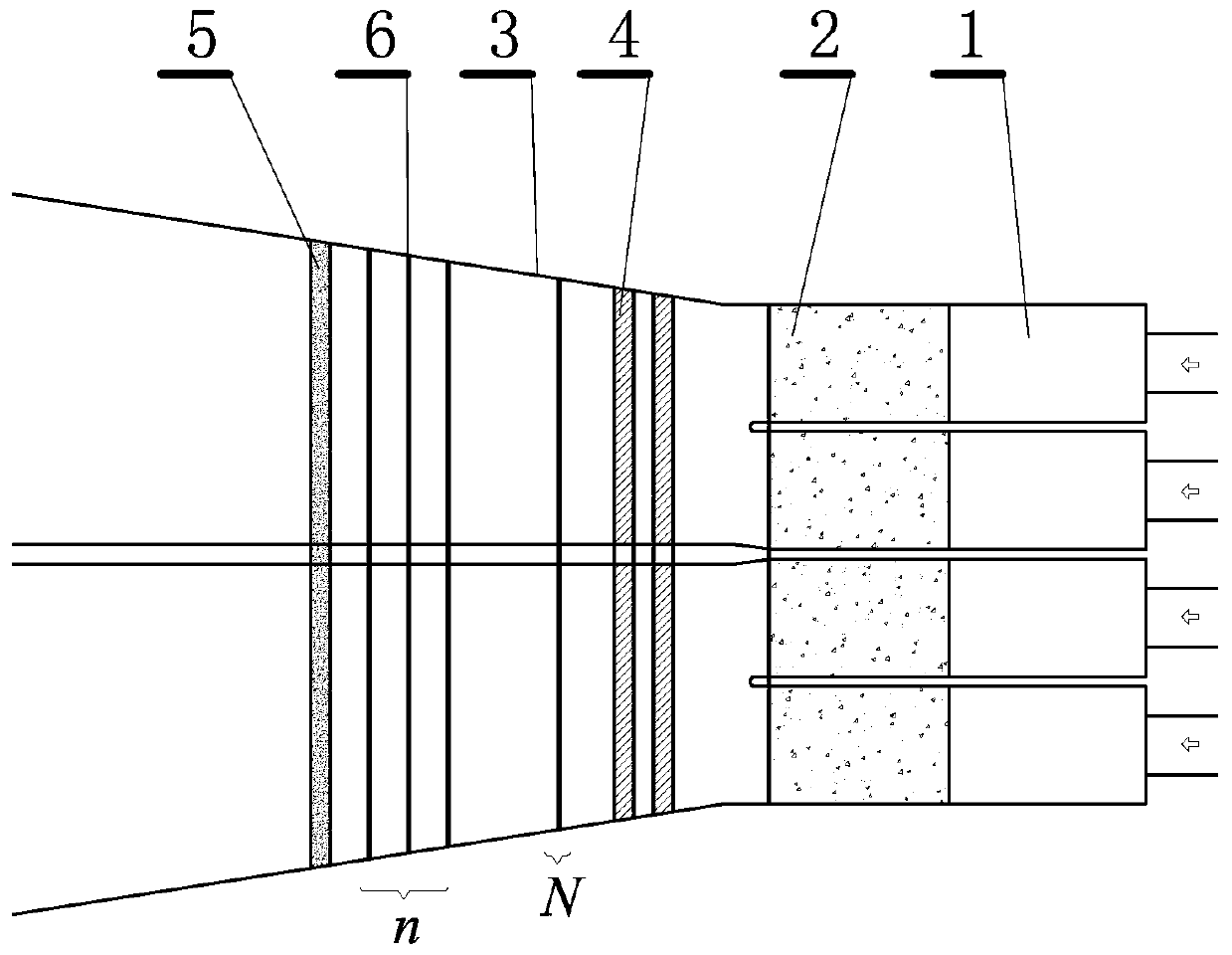

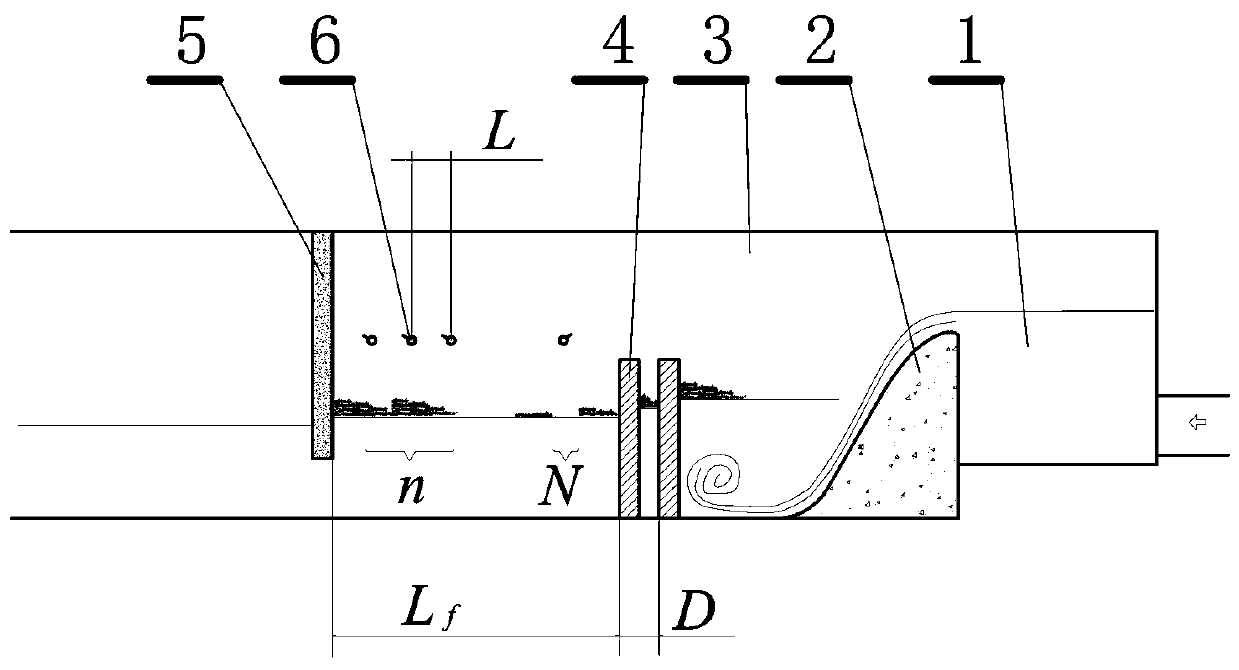

[0036] This embodiment is a kind of drainage defoaming system used in thermal / nuclear power plants, such as figure 1 , 2 shown. This embodiment includes: an overflow weir 2 arranged on the outlet side of the water inlet forebay 1 and a diffused rear pond channel 3, in which at least one energy-dissipating orifice plate 4 and a bubble-blocking wall are sequentially arranged 5. Sprinkling water facilities 6 are provided above the water area between the defoaming orifice plate and the foam blocking wall.

[0037] Before the system described in this embodiment was installed, after the drainage from the power plant fell from the overflow weir, a hydraulic jump was formed near the end of the overflow weir. was taken out to sea. In addition, affected by the hydraulic jump, the flow velocity distribution in the downstream cross-section of the siphon well is very uneven, and the water surface fluctuates greatly. The water level behind the weir is different, and the form of the hyd...

Embodiment 2

[0044] This embodiment is an improvement of the first embodiment, and is a refinement of the overflow weir in the first embodiment. The weir crest, the back water surface, and the floor of the pool channel in the diffusion section behind the weir of the overflow weir described in this embodiment are curved and sloped surfaces with smooth transitions.

[0045] In this example, the overflow weir with the smooth surface connecting the top of the weir and the water surface at the back of the weir is selected. Although it is a conventional overflow weir, it is very important for eliminating foam. This overflow weir can make the downstream water flow very stable, and cooperate with the downstream energy dissipation holes The high water level promoted by the board can minimize the generation of foam in the water and reduce the pressure of defoaming.

Embodiment 3

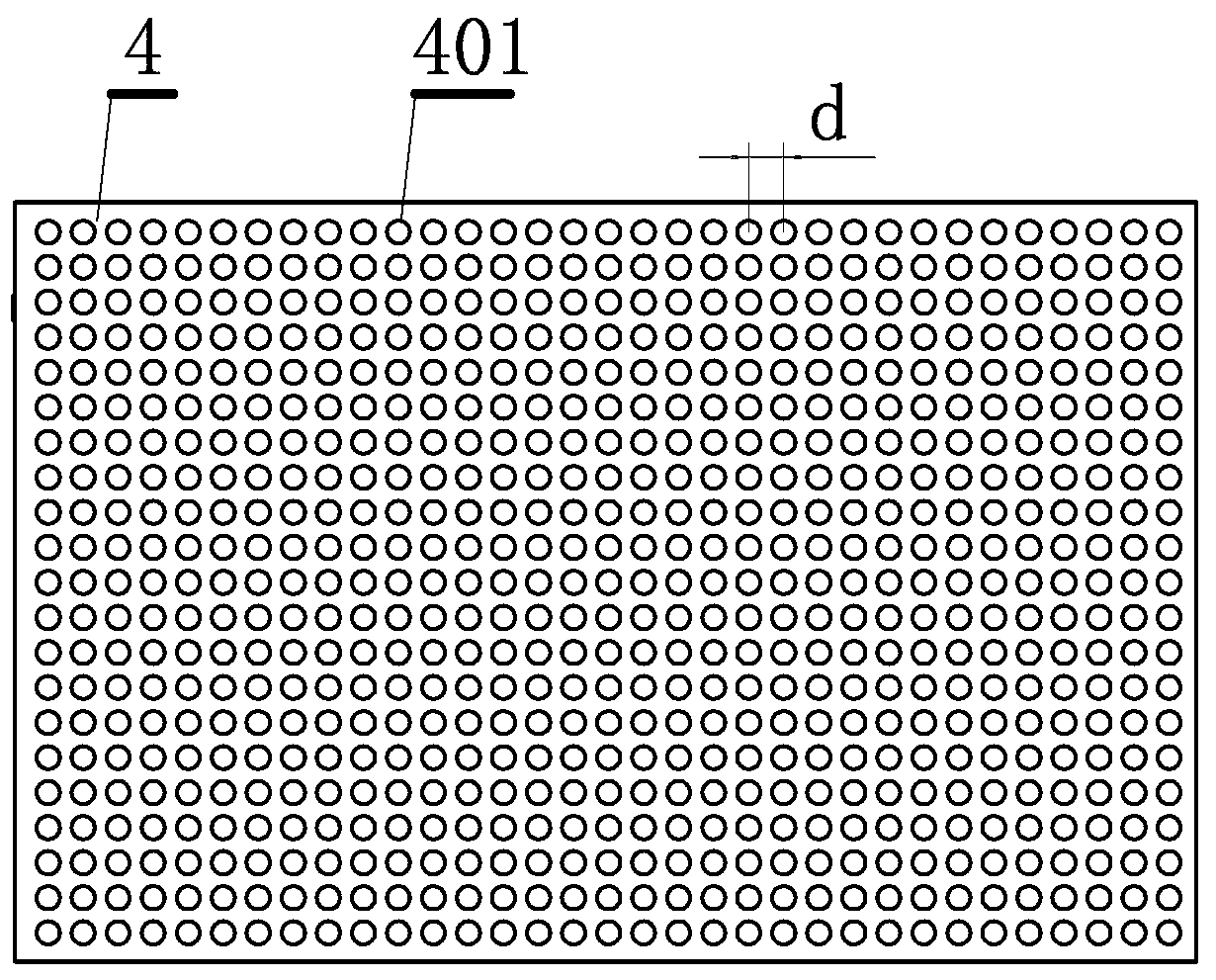

[0047] This embodiment is an improvement of the above-mentioned embodiment, and is a refinement of the above-mentioned embodiment about the energy-dissipating orifice. The energy dissipation orifice described in this embodiment is 2-4, and the distance D between each energy dissipation orifice is 800-1400 millimeters, see figure 2 , the holes on adjacent energy-dissipating orifice plates are arranged alternately.

[0048] Two energy-dissipating orifice plates are generally enough, but in some cases, if the drop of the overflow weir is large, so that the potential energy in the water is relatively large, more energy-dissipating orifice plates should be considered.

[0049] The distance between the orifice plates is related to the size of the foam in the water flow. The larger the foam is, the larger the distance between the orifice plates is. It can use energy dissipation and smooth water flow to intercept the foam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com