Heterogeneous sectional-type high abrasion resistant double-layer straight pipe used for concrete conveying

A segmented, concrete technology, applied in the direction of pipes, rigid pipes, pipeline protection, etc., can solve the problem of high composite cost, wear-resistant inner pipe, wear-resistant double-layer straight pipe, uneven wear, wear-resistant double-layer straight pipe of different materials Composite difficult and other problems, to achieve the effect of ensuring wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

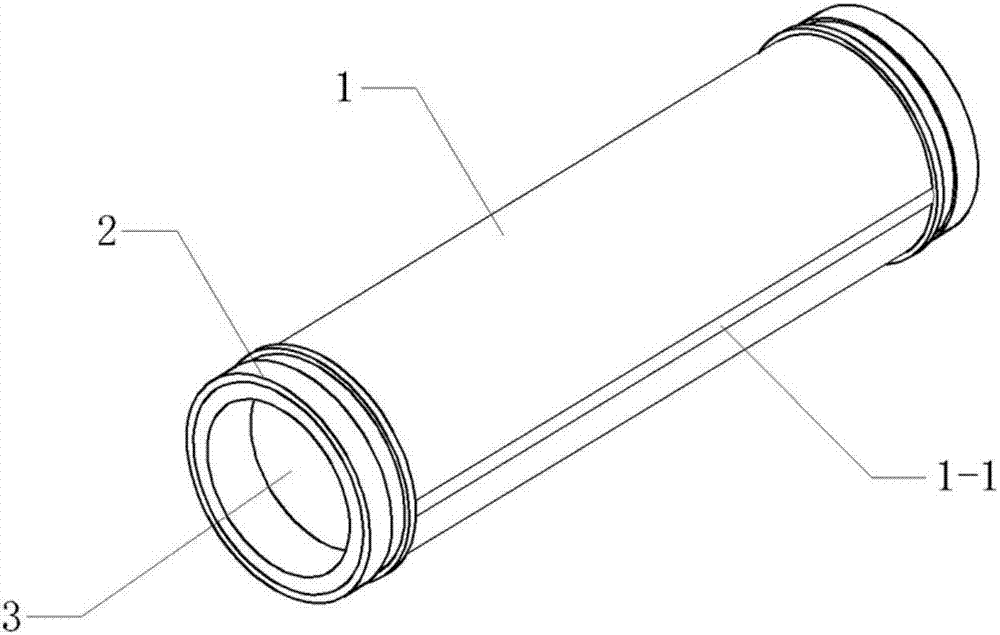

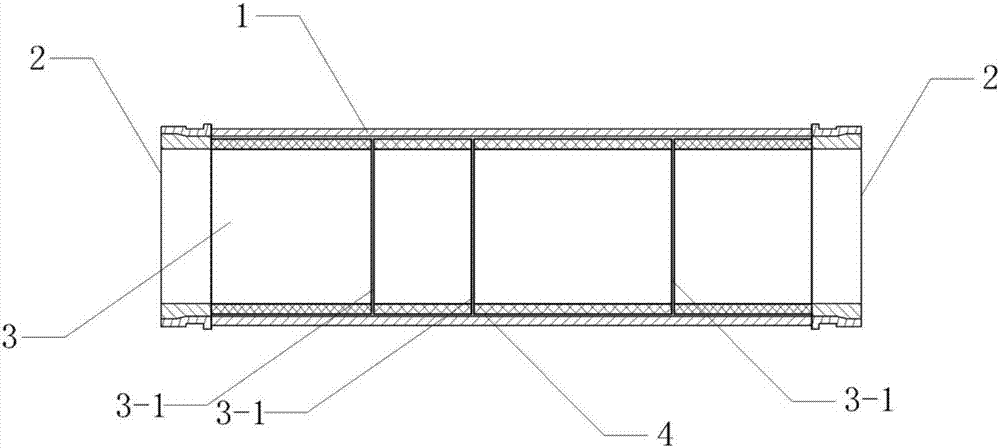

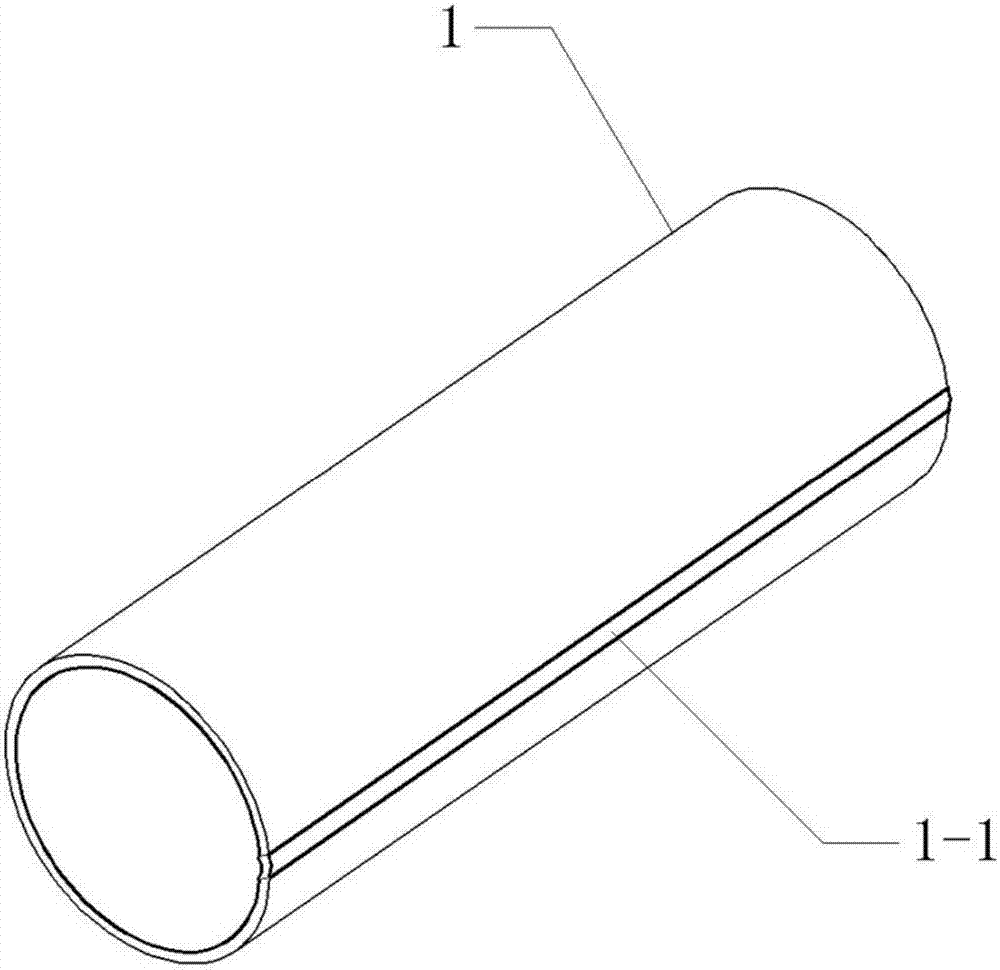

[0039] Such as figure 1 As shown, the heterogeneous segmented high wear-resistant double-layer straight pipe of the concrete pump truck in this embodiment consists of a protective outer pipe 1, a wear-resistant connecting flange 2, a segmented heterogeneous wear-resistant inner pipe 3 and a shock-absorbing filling cavity 4. In this embodiment, the protective outer pipe 1 is a welded steel pipe with a weld 1-1 on it; the segmented heterogeneous wear-resistant inner pipe 3 is composed of a filling channel 3-1 and a wear-resistant left end The inner tube 3-2, the middle wear-resistant inner tube 3-3 and the right end wear-resistant inner tube 3-4 are composed; the segmented heterogeneous wear-resistant inner tube 3 is installed inside the protective outer tube 1, and the wear-resistant connecting flange 2 The two ends of the protective outer tube 1 and the segmented heterogeneous wear-resistant inner tube 3 are designed to be packaged and reinforced by welding, and the shock-abso...

Embodiment 2

[0047] Such as Figure 5 As shown, in this embodiment, the main structure of the straight pipe is the same as that of Embodiment 1. It’s just that the segmented heterogeneous wear-resistant inner tube 3 is composed of a filling channel 3-1, a wear-resistant inner tube 3-2 at the left end, a wear-resistant inner tube 3-3 at the middle part, and a wear-resistant inner tube 3-4 at the right end; Grinding inner tube 3-3 is two or more; Between the wear-resistant inner tube 3-2 of the left end and the wear-resistant inner tube 3-3 of the middle part, the wear-resistant inner tube 3-4 of the right end part and the wear-resistant inner tube of the middle part A filling channel 3-1 is provided between the tubes 3-3 or between two adjacent wear-resistant inner tubes 3-3 in the middle (filling channels can also be provided); the wear-resistant inner tube 3-2 at the left end and the wear-resistant inner tube in the middle The tube 3-3 and the wear-resistant inner tube 3-4 at the right e...

Embodiment 3

[0053] In this embodiment, the basic structure of the straight pipe is the same as in Embodiment 1, but a specific wear-resistant connecting flange is provided. Such as Figure 6 As shown, the wear-resistant connecting flange 2 is composed of a flange 2-1 and a wear-resistant sleeve 2-2; the wear-resistant sleeve 2-2 is installed inside the flange 2-1.

[0054] The flange 2-1 in the present invention refers to: a component of the wear-resistant connecting flange 2; its function is to facilitate the connection and installation of straight pipes and other equipment.

[0055] The wear-resistant sleeve 2-2 of the present invention refers to: wear-resistant materials such as high-chromium cast iron, low-chromium cast iron, medium-chromium cast iron, wear-resistant cast iron, alloy steel, bearing steel, ceramics, hard alloy, polymer materials, etc. A wear-resistant sleeve made of one of them; its function is to prolong the service life of the wear-resistant connecting flange 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com