Plasma gas treatment device

A plasma and gas treatment technology, which is applied in the direction of gas treatment, separation methods, and dispersed particle separation, etc., can solve the problems of unsatisfactory gas treatment effects, achieve high working intensity, uniform contact, and avoid gas short circuit effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] This embodiment provides a plasma gas processing device, which enhances the gas disturbance in the reaction chamber, not only has a good gas processing effect, but also has a simple structure and low manufacturing cost.

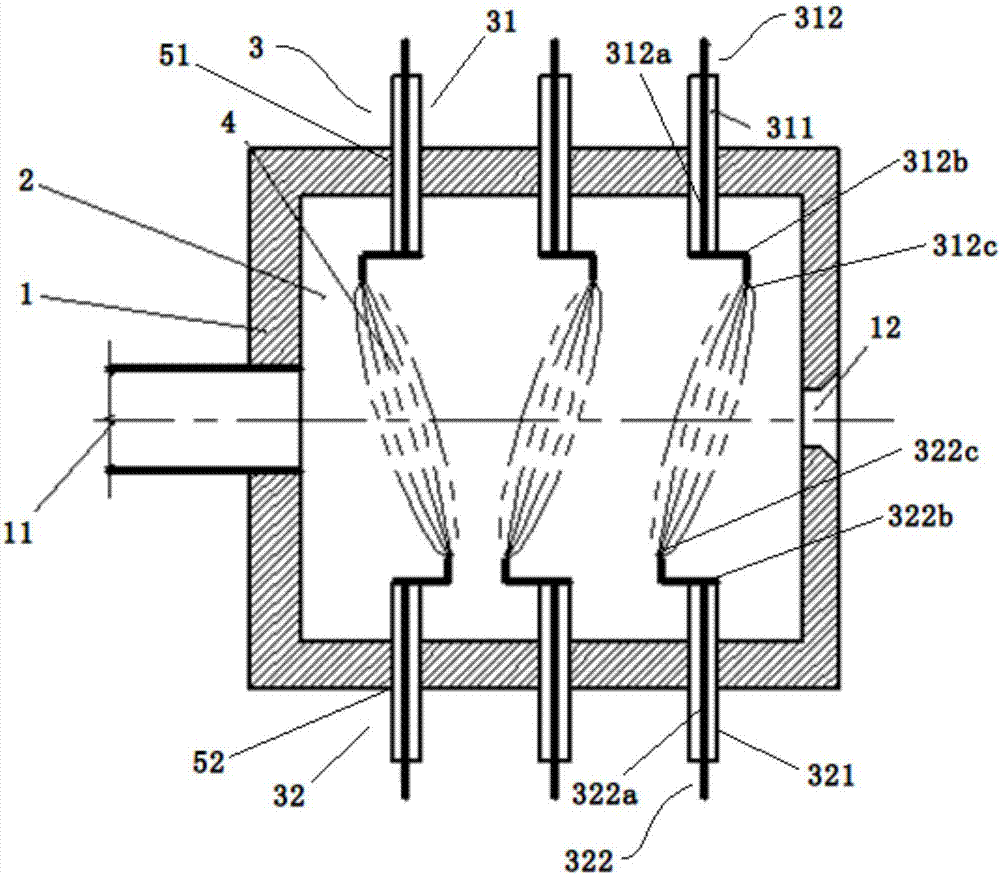

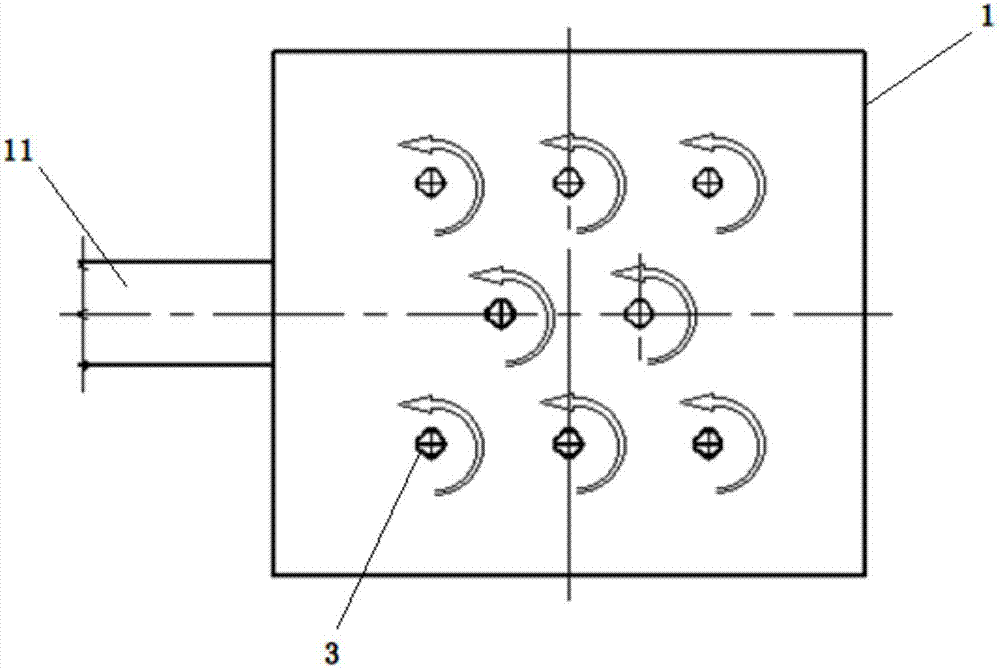

[0034] See figure 1 with figure 2 ,among them figure 1 Is a schematic structural diagram of a plasma gas processing device according to an embodiment of the present invention; figure 2 Shown is a top view of a plasma gas processing apparatus according to an embodiment of the present invention.

[0035] It can be seen from the figure that the plasma gas processing device of this embodiment includes a housing 1 which defines a reaction chamber 2; an air inlet 11 and an air outlet 12 are respectively provided at the front and rear of the housing 1. The gas inlet 11 and the gas outlet 12 are used to guide gas into and out of the reaction chamber 2; a plurality of plasma generating units 3 arranged in an array, The plasma generating units 3 of adjacent array...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com