Unit module of telescopic soft body robot

A unit module and robot technology, applied in the field of robotics, can solve the problems of small load of soft robots and weak execution force of a single module, and achieve the effects of simple structure, increased linear displacement, and increased working space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments in no way limit the present invention.

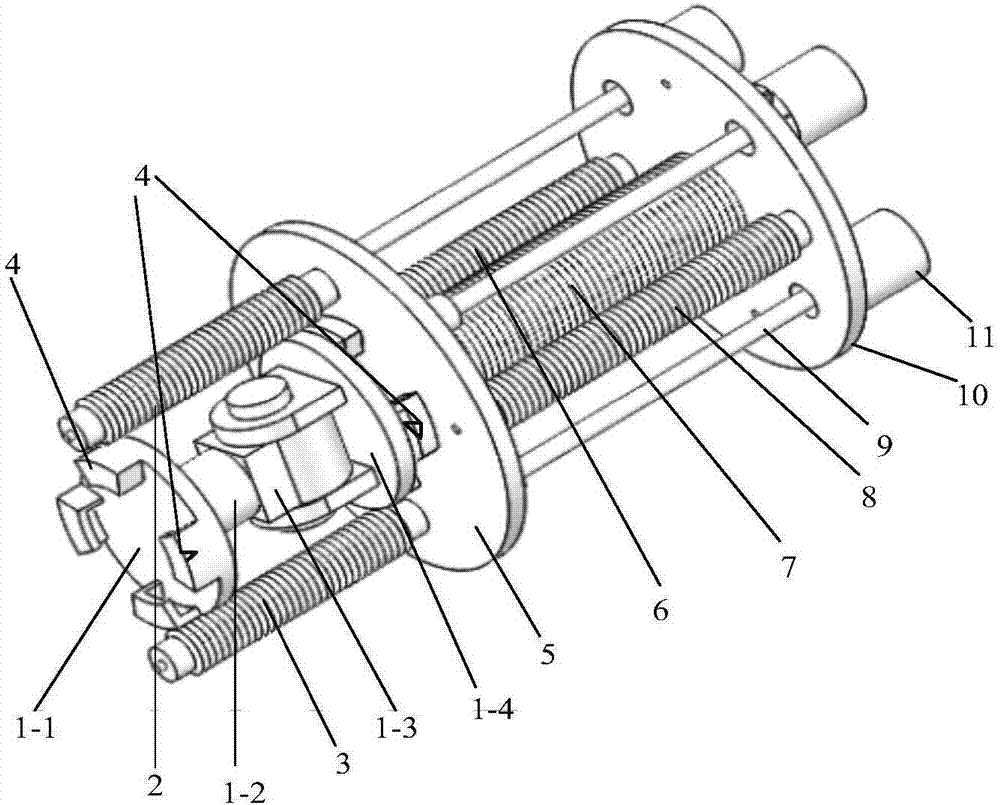

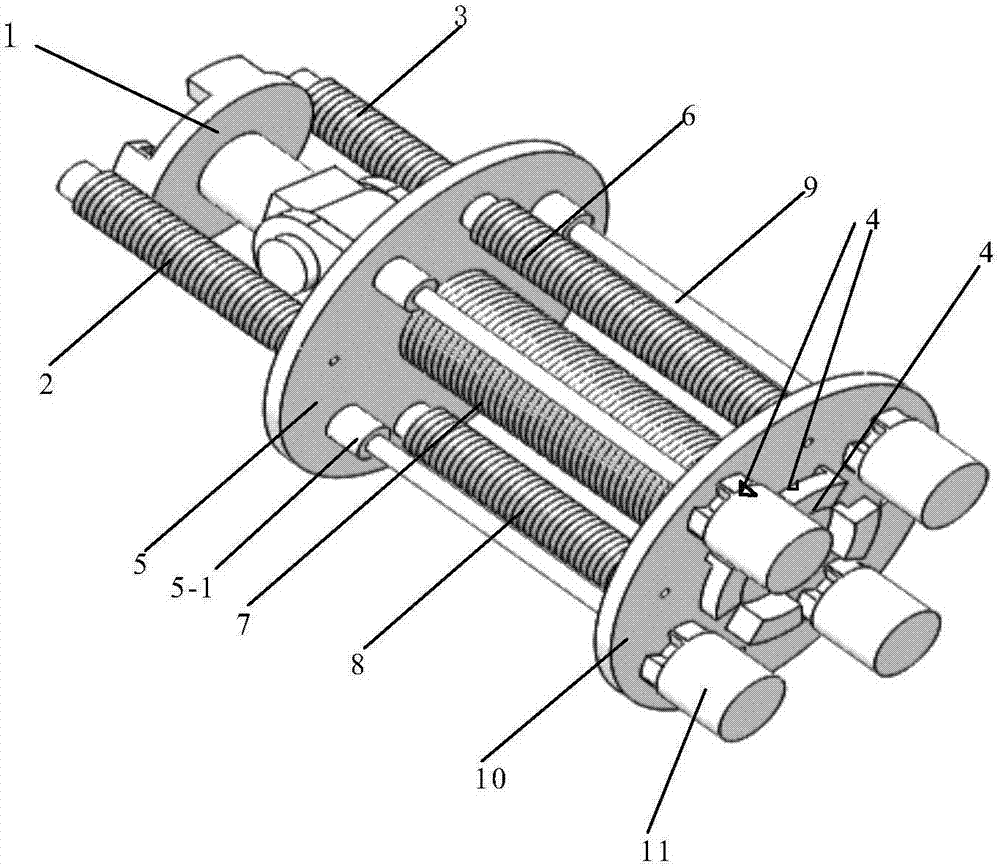

[0026] Such as Figure 1~2 As shown, the scalable soft robot unit module is a cylindrical structure with a bottom diameter of 30cm and a height of 42cm from the overall appearance;

[0027] Specifically, the scalable soft robot unit module includes a steering drive mechanism, a wrist joint movement mechanism, a drive cable assembly and a communication cable assembly;

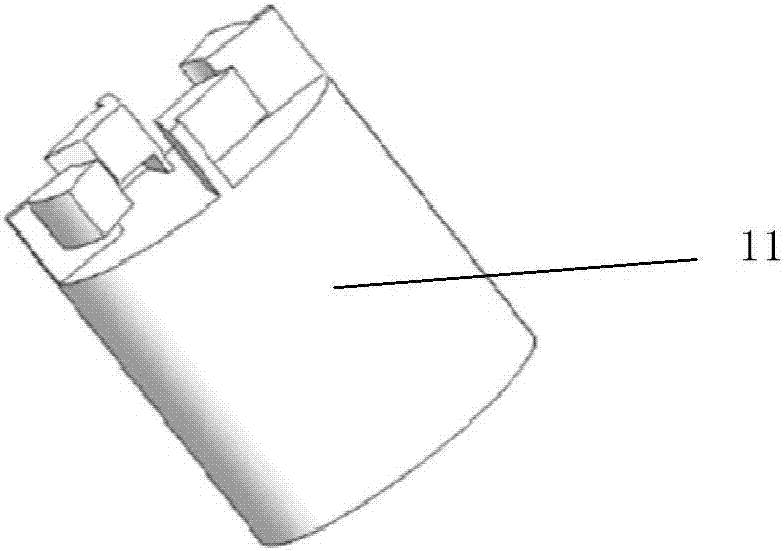

[0028] The steering drive mechanism includes a steering drive front panel 5, a telescopic pneumatic tube 7, a steering drive rear panel 10, four drive ropes 9 and four DC motors 11; wherein,

[0029] The two ends of the telescopic pneumatic tube 7 are bonded and fixed respectively at the center of the bottom surface of the steering drive front panel 5 and at the center of the top surface of the steering drive r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com