Method for preparing large-area structural coloration pattern by ink-jet printing

A technology of inkjet printing and structural color generation, applied in the directions of copying/marking method, printing, ink, etc., can solve the problems of high price and limited use of the second equipment, and achieve the effect of strong practicability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

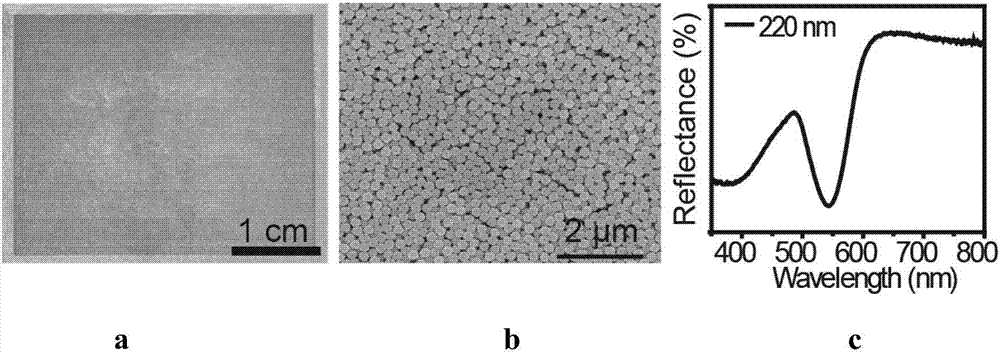

[0029] Inkjet printing CdS ink to obtain large-area red structural color patterns.

[0030] First prepare monodisperse CdS colloidal microspheres, the specific preparation method is as follows:

[0031] Take by weighing 6g polyvinylpyrrolidone powder (PVP), add 150mL diethylene glycol, then add the cadmium nitrate and thiourea powder of equal amount of substance, the amount of substance of cadmium nitrate and thiourea is 15mmol, stir until all powders dissolve completely . The solution was heated to 160° C., kept for 5 hours, and then naturally cooled to room temperature. The product was centrifuged, washed with ethanol and water three times and dried.

[0032] Weigh a certain amount of monodisperse CdS microsphere powder and grind it fully, wherein the content of monodisperse colloidal microspheres is 12wt%, the content of ethylene glycol is 5wt%, the content of ethanol is 10wt%, and the content of glycerin is 5wt%. , the content of PVP is 2.7wt%, the content of tributyl ph...

Embodiment 2

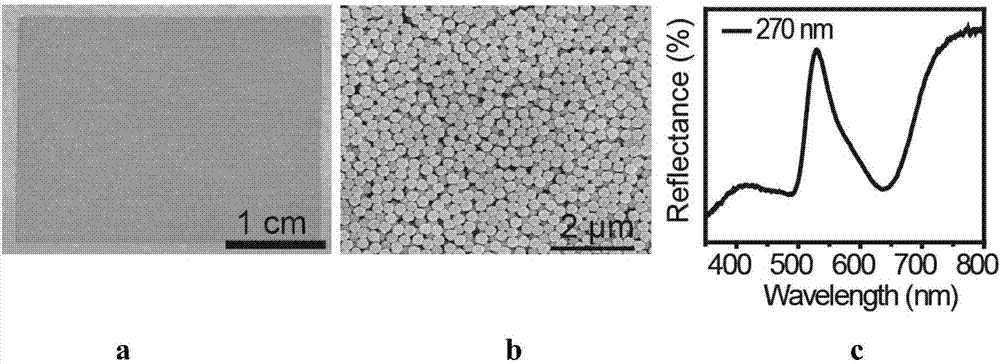

[0035] Inkjet printing CdS ink to obtain large-area red structural color patterns.

[0036] First prepare monodisperse CdS colloidal microspheres, the specific preparation method is as follows:

[0037] Take by weighing 6g polyvinylpyrrolidone powder (PVP), add 150mL diethylene glycol, then add the cadmium nitrate and thiourea powder of equal amount of substance, the amount of substance of cadmium nitrate and thiourea is 20mmol, stir until all powders dissolve completely . The solution was heated to 162°C, kept for 6 hours, and then naturally cooled to room temperature. The product was centrifuged, washed with ethanol and water three times and dried.

[0038] Weigh a certain amount of monodisperse CdS microsphere powder and grind it fully, wherein the content of monodisperse colloidal microspheres is 15wt%, the content of ethylene glycol is 5wt%, the content of ethanol is 10wt%, and the content of glycerol is 5wt%. , the content of PVP is 3wt%, the content of tributyl phosph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com