Plasma nitriding heat treatment process of 35crmov gear sleeve or gear ring for centrifugal compressor

A centrifugal compressor, ion nitriding technology, applied in heat treatment furnaces, heat treatment equipment, metal material coating technology, etc., can solve problems such as not meeting actual needs, achieve increased hardness, increased contact fatigue strength, and improved core performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 35CrMoV gear ring material for centrifugal compressor, its effective thickness is 100mm, its chemical composition: C: 0.048wt.%; Si: 0.42wt.%; Mn: 0.80wt.%; Cr: 13.70wt.%; Mo: 1.50 wt.%; S: 0.004 wt.%; P: 0.026 wt.%; V: 0.29 wt.%; Fe: balance. It is subjected to ion nitriding heat treatment, including the following steps:

[0036] (1) Normalizing treatment, heat preservation at 900°C for 2.5 hours, then air cooling;

[0037] (2) Quenching treatment, heat preservation at 900°C for 2.5 hours, then oil cooling;

[0038] (3) Tempering treatment, heat preservation at 600°C for 4.0 hours, then air cooling;

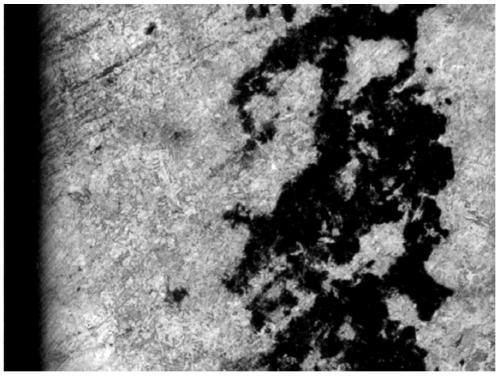

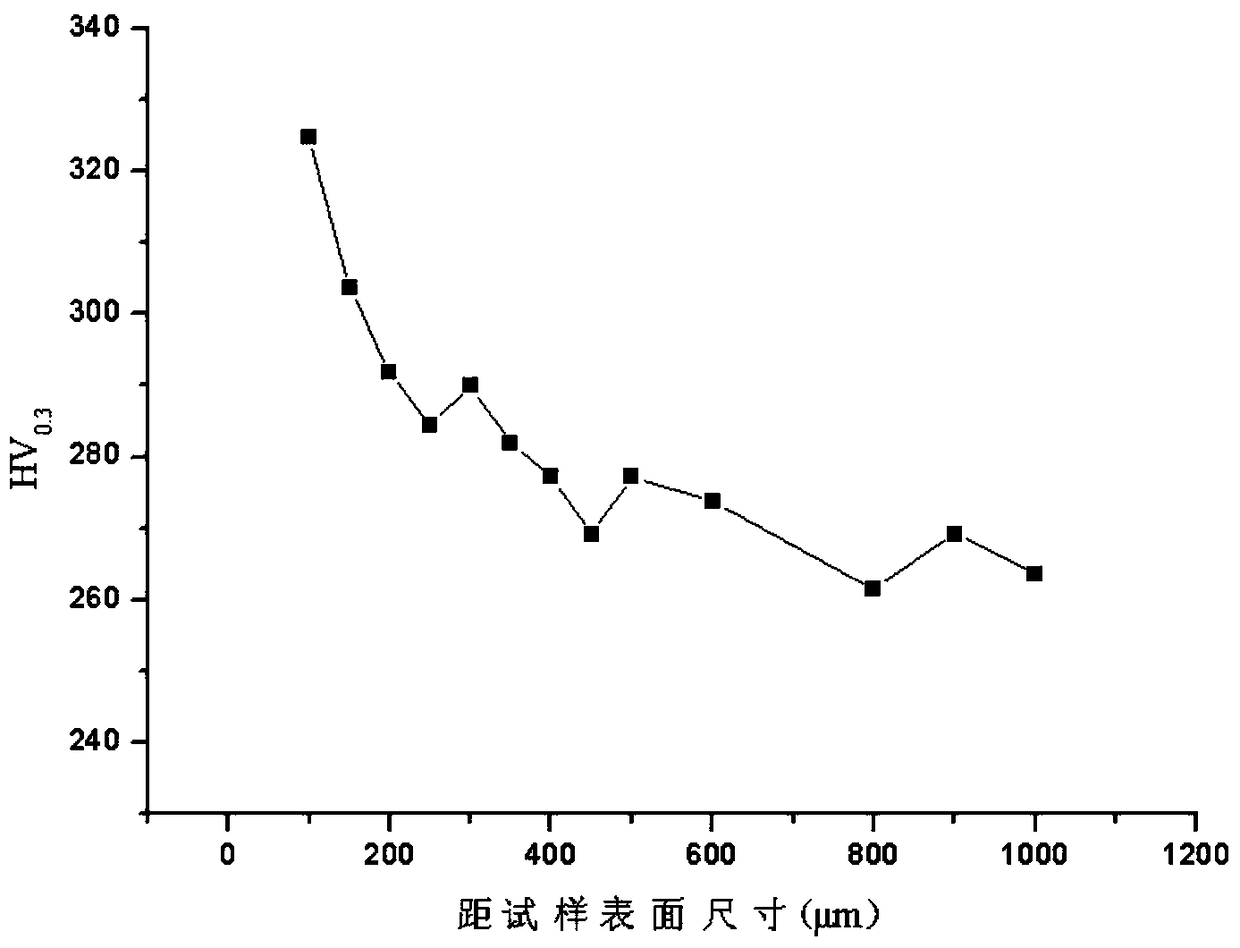

[0039] (4) Ion nitriding treatment, ion nitriding at 520°C for 22.0 hours, furnace cooling to 200°C, and then air cooling out of the furnace;

Embodiment 2

[0052]35CrMoV gear ring material for centrifugal compressor, its effective thickness is 100mm, its chemical composition: C: 0.048wt.%; Si: 0.42wt.%; Mn: 0.80wt.%; Cr: 13.70wt.%; Mo: 1.50 wt.%; S: 0.004 wt.%; P: 0.026 wt.%; V: 0.29 wt.%; Fe: balance. It is subjected to ion nitriding heat treatment, including the following steps:

[0053] (1) Normalizing treatment, heat preservation at 900°C for 2.5 hours, then air cooling;

[0054] (2) Quenching treatment, heat preservation at 900°C for 2.5 hours, then oil cooling;

[0055] (3) Tempering treatment, heat preservation at 600°C for 4.0 hours, then air cooling;

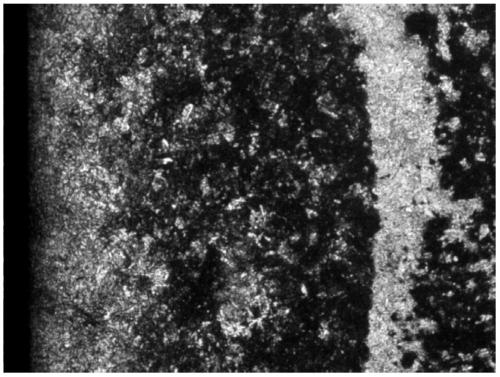

[0056] (4) Ion nitriding treatment, ion nitriding at 520°C for 18.0 hours, furnace cooling down to 200°C, and then air cooling out of the furnace;

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com