Resistance-type stretchable multi-axis force sensing yarn

A resistive, multi-dimensional force technology, applied in the direction of yarn, textiles and papermaking, can solve the problem of not being able to measure multi-dimensional forces such as stretching, bending and torsion at the same time, and achieve good elasticity, reduced slip, and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

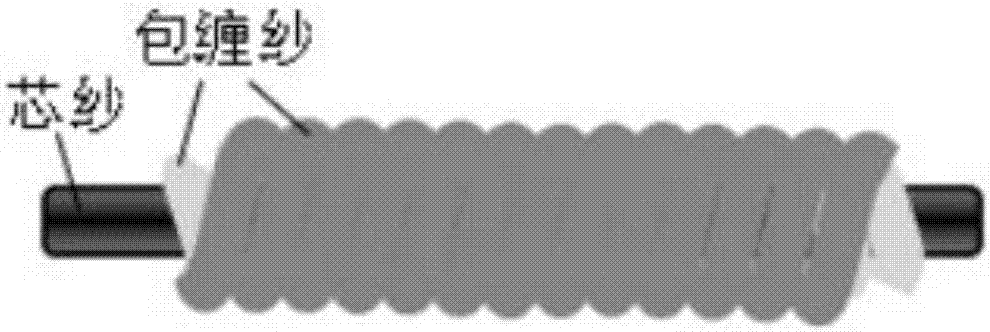

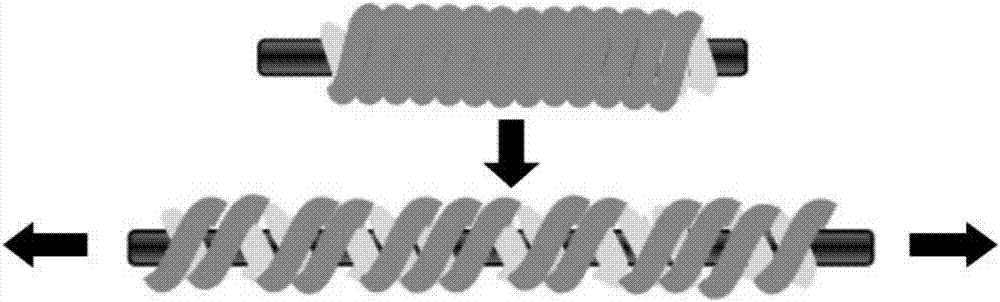

[0030] Example 1: First, the conductive nylon filament is wrapped around the spandex fiber with a certain wrapping angle in the Z twist direction, and then wrapped in the S twist direction to obtain a negative Poisson's ratio structured yarn with Z twist in the inner layer and S twist in the outer layer Wire. The pre-stretching process diagram of the conductive treatment of elastic covered yarn is shown in Figure 5 As shown, according to the design of the sizing process, the yarn is impregnated under a certain stretching state, so that the yarn is fully adsorbed, and the yarn is stretched by using the speed difference between the two pressing rollers, which is convenient for realizing industrial chemical production.

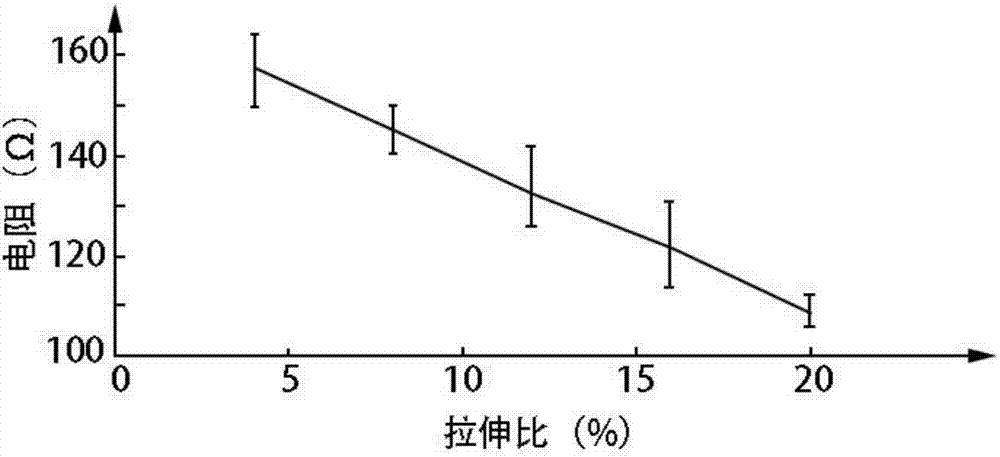

[0031] Due to the unique helical covering structure, the yarn sensor has greater stretchability and better reversibility. When the yarn is stretched and deformed, the microscopic helical structure of the yarn is also changing. The change of the helical structur...

Embodiment 2

[0032] Embodiment 2: Refer to Embodiment 1 for the negative Poisson's ratio yarn manufacturing method, but adopt the method of wrapping the inner layer of the core yarn with Z twist in the outer layer of nylon, and refer to Embodiment 1 for the method of conductive treatment. The negative Poisson’s ratio yarn sensor with S twist on the inner layer and Z twist on the outer layer has the same resistance response as in Example 1 when stretched and bent, but the resistance change when twisted is opposite to that of Example 1, clockwise Twisting the yarn is tight inside and loose outside, and the contact between the inner and outer wrapping yarns is reduced, and the contact resistance becomes smaller, so that the resistance of the negative Poisson’s ratio yarn decreases. The contact becomes larger and the overall yarn resistance increases.

[0033] It can be seen that the resistive stretchable multi-dimensional force sensing yarn of the present invention can not only achieve high s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com