Foam generator, toilet bowl and foam generation method

A technology for foam generators and toilets, which is applied to sanitary equipment for toilets, flushing toilets, water supply devices, etc. It can solve the problems of reduced recycling, inconvenient use, and water waste workload, so as to increase the number of times of use and reduce costs. , Save the effect of multiple uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

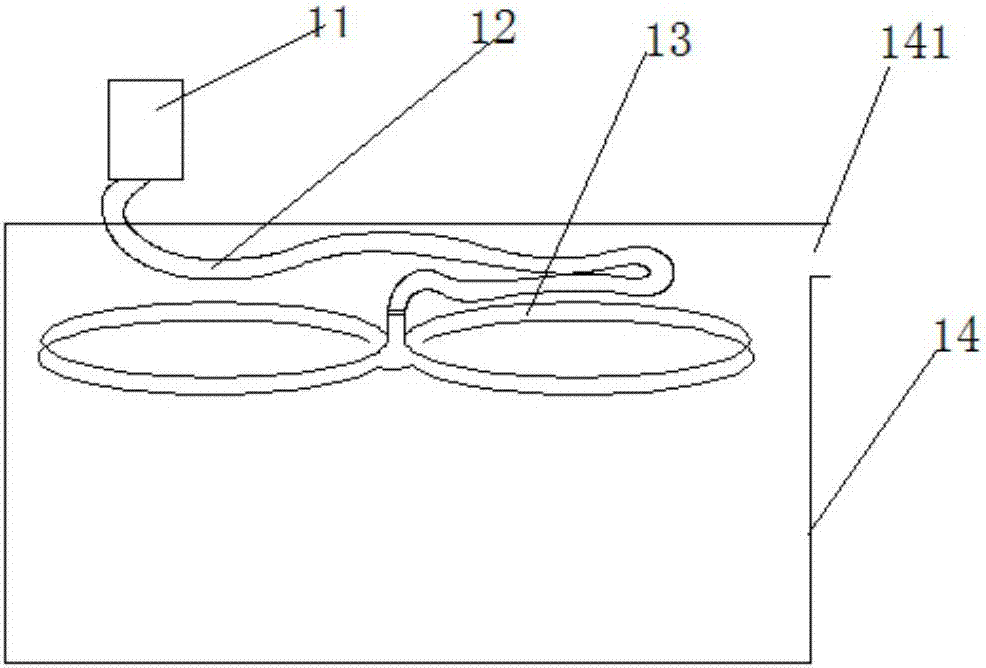

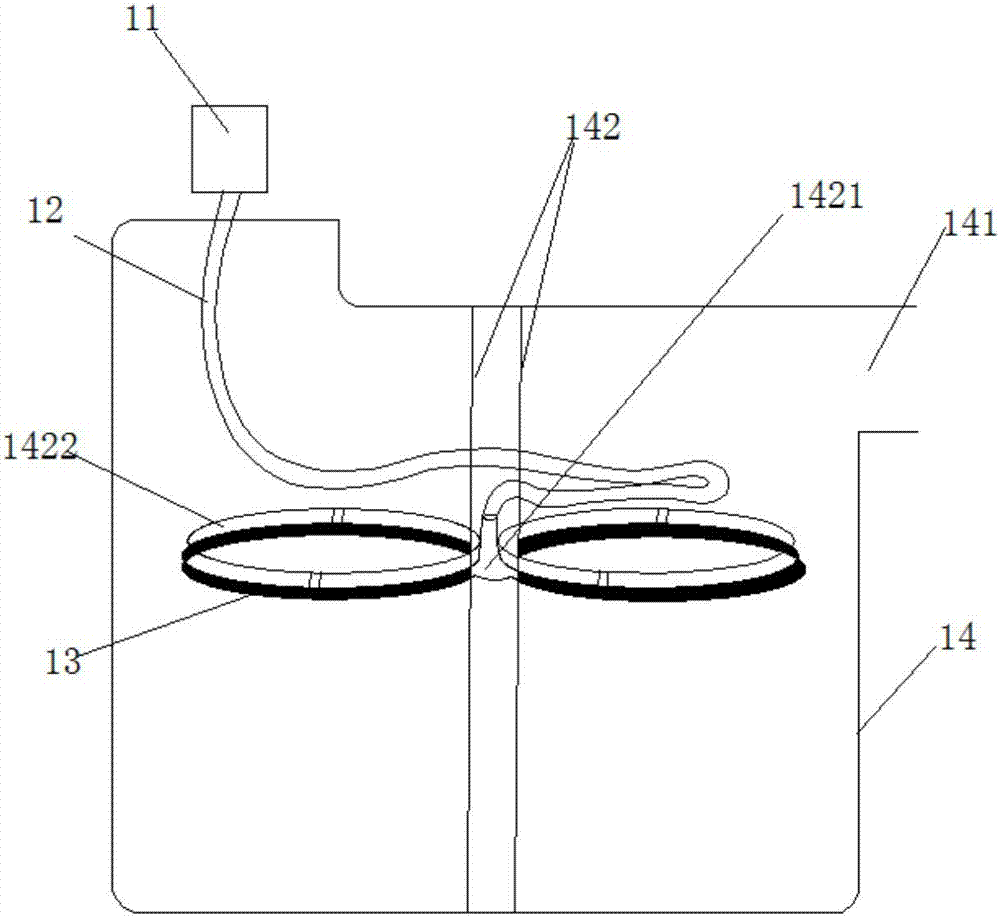

[0046] Such as figure 1 As shown in -2, the foam generator provided by the present invention includes: an air intake assembly 11, a connecting pipe 12, an aeration pipe 13 and a control device; one end of the connecting pipe 12 is connected to the air intake assembly 11, and the other end is connected to the aeration pipe 13 connected, and the aeration pipe 13 is arranged in the foaming box 14, and the foaming box 14 is provided with a foam outlet 141; the control device is electrically connected with the air intake assembly 11.

[0047] The foam generator provided by the present invention includes an air intake assembly 11, a connecting pipe 12, an aeration pipe 13 and a control device. It is arranged in the foaming box 14 , and the control device is electrically connected with the air intake assembly 11 . During use, air enters from the air intake assembly 11, and is discharged from the aeration pipe 13 through the connecting pipe 12. The aeration pipe 13 is arranged in the...

Embodiment 2

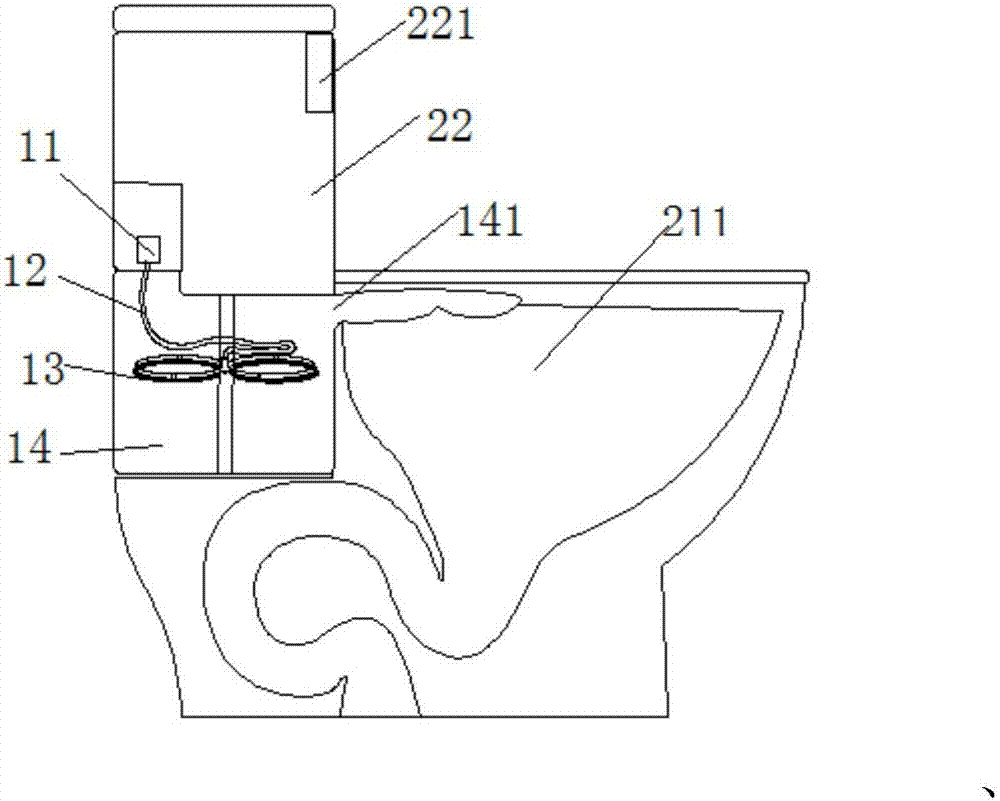

[0065] Such as image 3 As shown in -5, the present invention also provides a toilet, including a toilet seat 21, a water tank 22 and a foam generator; Be provided with foaming agent box 221 inside, foaming agent box 221 is connected with foaming box 14 by pipeline; Toilet seat 21 is also provided with toilet lid, toilet chamber 211 and toilet seat 21 circles, toilet lid is positioned at toilet seat 21 tops, toilet chamber The inside of 211 is provided with spray water outlet 2111, and there are multiple spray water outlets 2111, which are located at the top edge of the toilet cavity 211, and the foam outlet 141 communicates with the spray water outlet 2111; the bottom of the toilet seat 21 is provided with a sewage Mouth 212, the toilet seat 21 is also provided with a water inlet and a spray channel, and the water inlet communicates with the beginning of the water tank 22 and the spray channel, and water can spray towards the sewage outlet 212 direction through the spray chan...

Embodiment 3

[0083] The present invention also provides a foam generation method, comprising the steps of:

[0084] S1: When the air intake assembly 11 receives the command from the control device, the air intake assembly 11 starts, and the air intake assembly 11 generates airflow, which enters the connecting pipe 12, and then the airflow enters the aeration pipe 13 to generate foam in the foaming box 14, After the foam is discharged from the foam outlet 141, it flows into the toilet cavity 211 from the spray water outlet 2111 provided inside the toilet cavity 211, forming an insulating splash-proof layer in the toilet cavity 211;

[0085] S2: When the third control valve receives the command from the control device, the third control valve is opened to flush the spray water into the toilet chamber 211;

[0086] Wherein the intake assembly 11 and the third control valve are opened and closed simultaneously or separately;

[0087] S3: When the amount of foam liquid reaches the lowest posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com