Linkage balance beam-pumping unit

A beam pumping unit, balancing technology, applied in the direction of machine/engine, liquid variable capacity machinery, mechanical equipment, etc., can solve the problem of poor balance effect of the beam pumping unit, difficult to meet the requirements of production and processing, Due to the high requirements of screw manufacturing accuracy, the effect of obvious balance effect, smooth and stable oil pumping speed, and uniform load on the structure can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention will be further described in detail in conjunction with the accompanying drawings, but the scope of protection of the present invention is not limited to the following description.

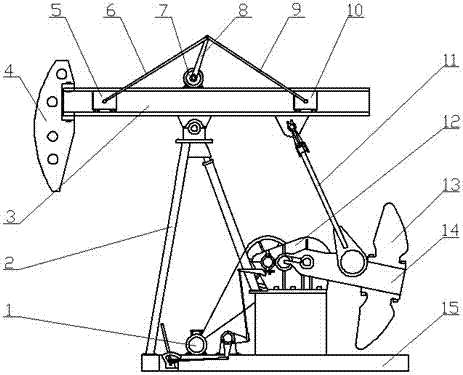

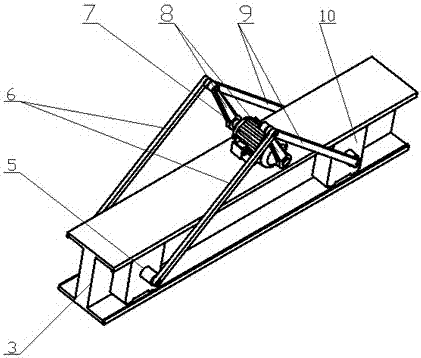

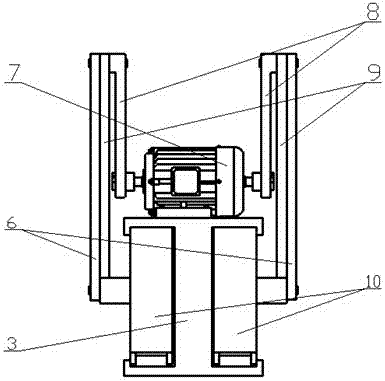

[0017] Such as figure 1 , figure 2 , image 3 As shown, a linkage balanced beam pumping unit of the present invention consists of an asynchronous motor 1, a bracket 2, a beam 3, a donkey head 4, a left double slider 5, a left double connecting rod 6, a double shaft motor 7, and a double crank 8, right double connecting rod 9, right double slide block 10, connecting rod 11, speed reducer 12, counterweight 13, crank 14, base 15 forms.

[0018] The biaxial motor 7 is fixedly installed above the bearing support position of the beam 3, with the output shaft of the biaxial motor 7 as the rotation center, the head end of the double crank 8 is connected through the pin shaft, and the other end of the double crank 8 is connected to the left side through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com