Shake and de-bubble structure and ultrasonic liquid concentrate test device

A testing device, liquid concentration technology, applied in the direction of measuring device, using sound wave/ultrasonic wave/infrasonic wave to analyze fluid, using sound wave/ultrasonic wave/infrasonic wave to conduct material analysis, etc. It can solve the problem of ultrasonic signal attenuation, probe damage life, large probe impact, etc. problem, achieve the effect of reducing direct impact and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

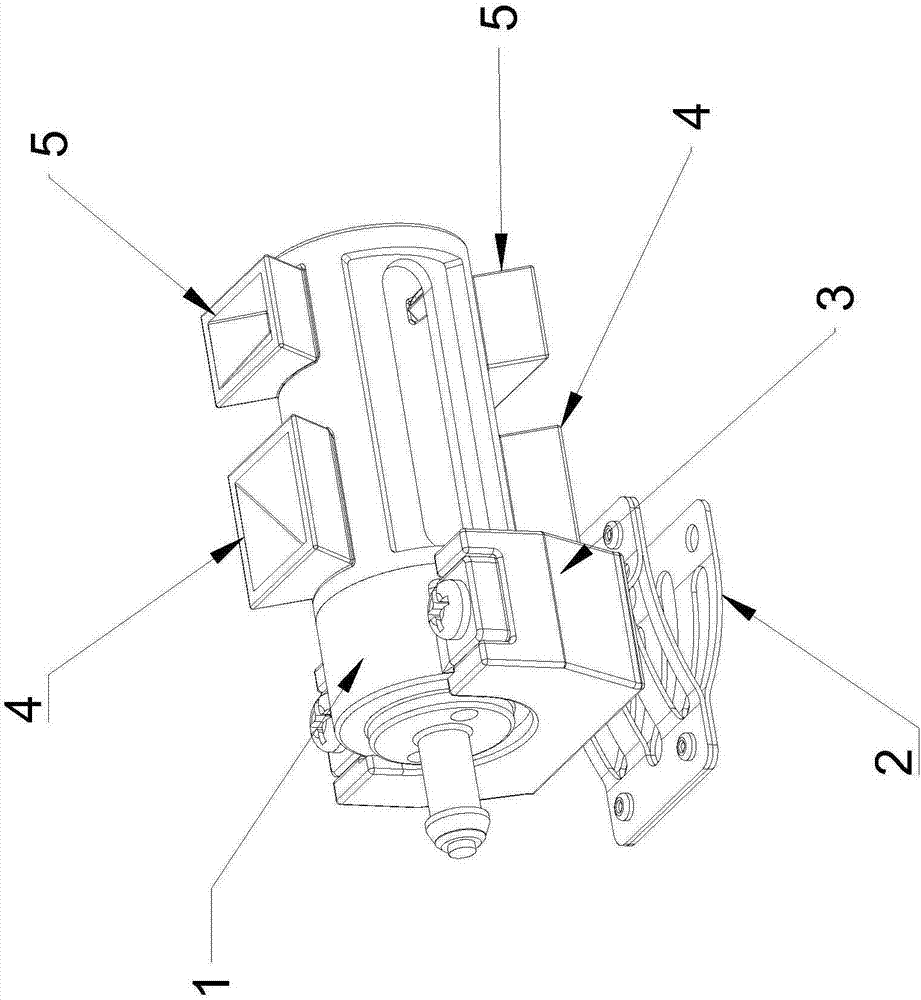

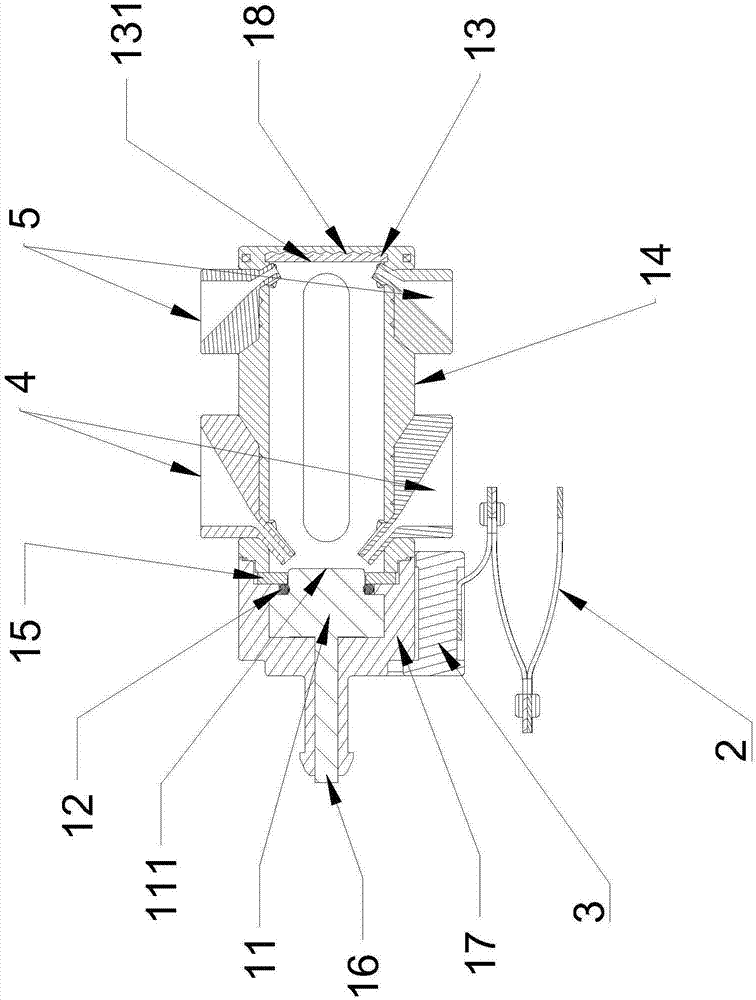

[0085] like Figure 1 to Figure 3 As shown, an ultrasonic liquid concentration detection device includes a probe 1 of an ultrasonic liquid concentration test device, a probe mounting base 3 , an oscillator 2 , a diversion jet 4 and a diversion jet 5 .

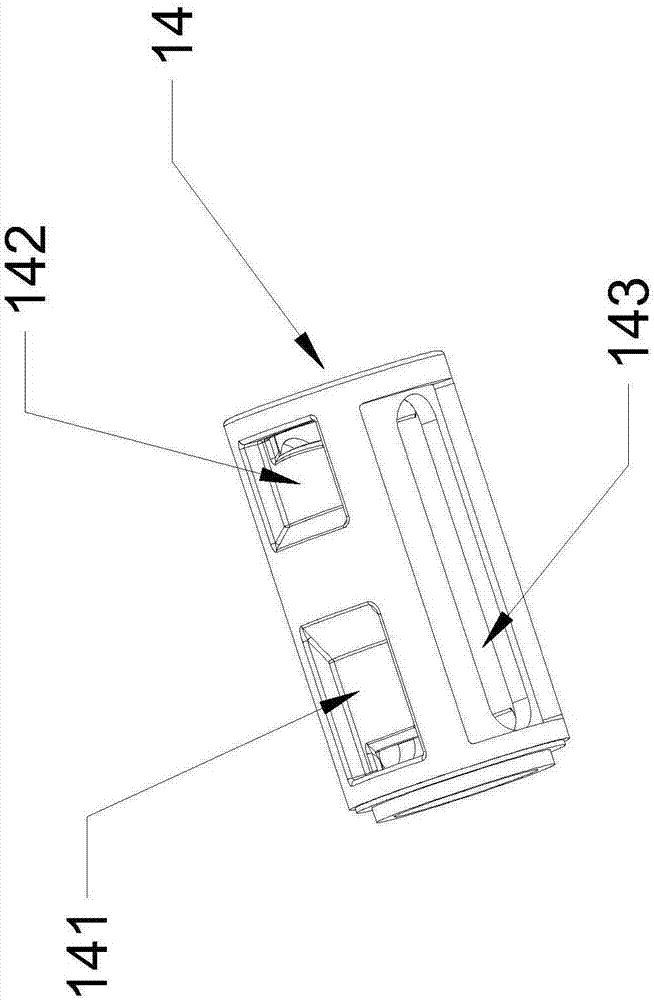

[0086] The probe 1 is designed as an integrated engineering plastic part, wherein the ultrasonic generator 11, the core component of the ultrasonic liquid concentration testing device, is wrapped by engineering plastics; another key functional part of the ultrasonic liquid concentration testing device, the ultrasonic reflection sheet 13 is inlaid Enter the column body 14.

[0087] Specifically, the sonotrode 11 is injection molded through an embedded mold through engineering plastics, and is inlaid into the sonotrode base 17, and the tail signal transmission line 16 of the sonotrode is also inlaid together; The mold is injection molded, and the embedded hardware material is an ultrasonic reflector.

[0088] The column body 14...

Embodiment 2

[0101] like Figure 1 to Figure 3 As shown, an ultrasonic liquid concentration detection device includes a probe 1 of the ultrasonic liquid concentration test device, a mounting base 3 for the probe 1 , an oscillating body 2 , a diversion jet body 4 and a diversion jet body 5 .

[0102] The probe 1 is designed as an integrated engineering plastic part, wherein the ultrasonic generator 11, the core component of the ultrasonic liquid concentration testing device, is wrapped by engineering plastics; another key functional part of the ultrasonic liquid concentration testing device, the ultrasonic reflection sheet 13 is inlaid Enter the column body 14.

[0103] Specifically, the sonotrode 11 is injection molded through an embedded mold through engineering plastics, and is inlaid into the sonotrode base 17, and the tail signal transmission line 16 of the sonotrode is also inlaid together; The mold is injection-molded, and the embedded hardware material is an ultrasonic reflection s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com