Copper clad ceramic substrate facilitating laser cutting

A copper-clad ceramic substrate and laser cutting technology, which is applied in the direction of semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve the problems of difficulty in breaking the process and achieve the effect of preventing air leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

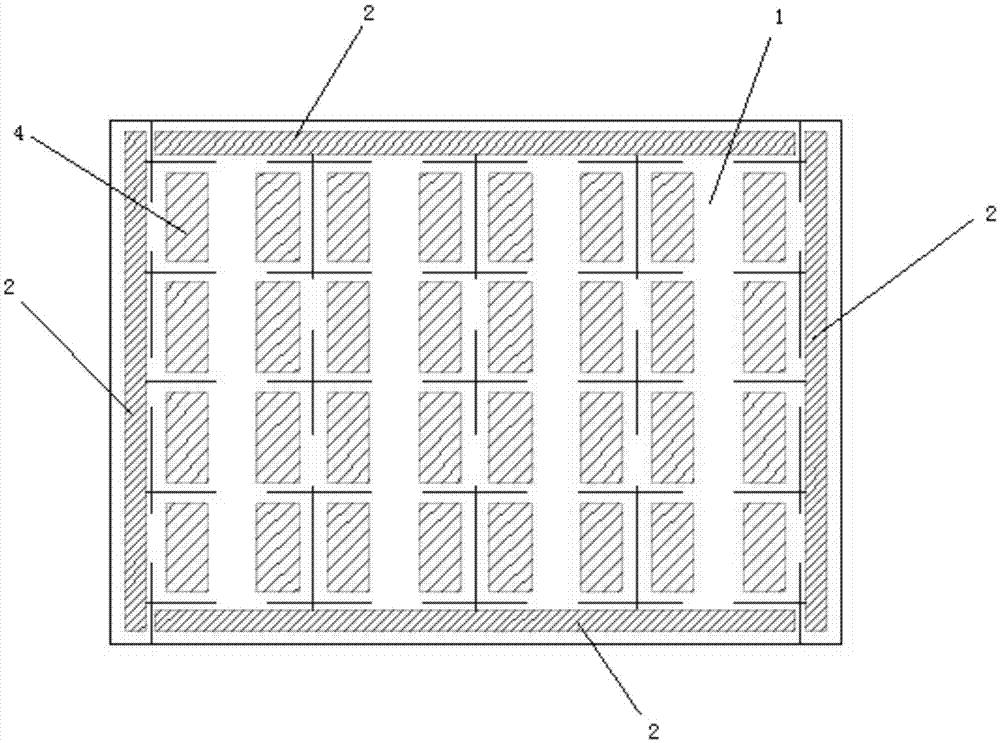

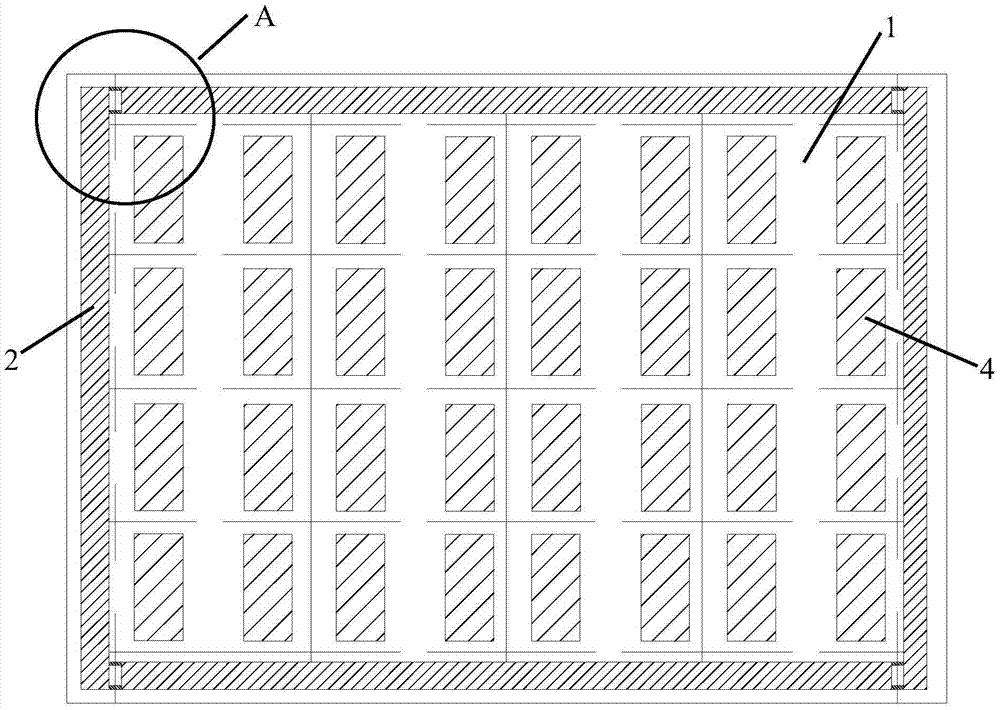

[0022] Such as Figure 2-3 A copper-clad ceramic substrate that is convenient for laser cutting is shown, comprising: a copper-clad ceramic substrate body 1 , a process side 2 and a copper strip 3 .

[0023] The copper-clad ceramic substrate body 1 has a rectangular structure.

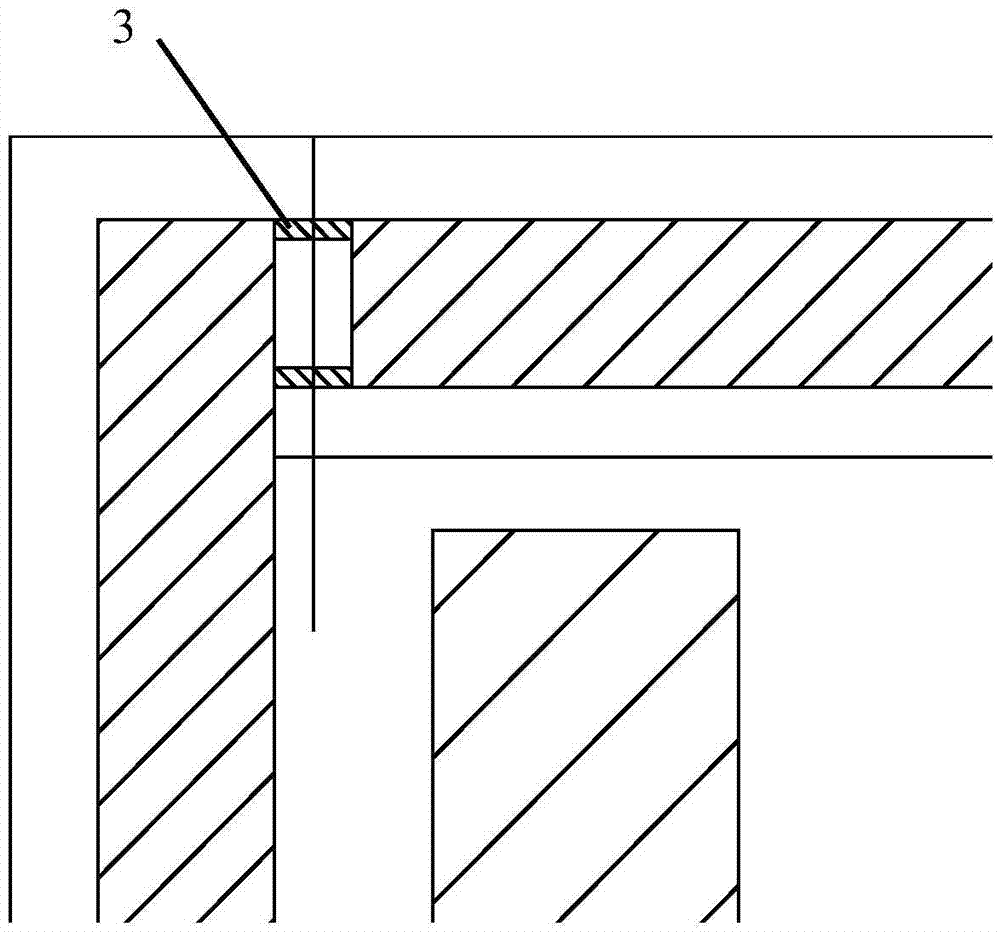

[0024] The process side 2 is arranged around the edge of the copper-clad ceramic substrate body 1, and consists of four straight sides: upper, lower, left, and right; two mutually perpendicular process sides 2 are connected by copper strips 3 to form a connection unit, and the copper strips The width of 3 is smaller than the width of process side 2. The width of the process side is 5mm.

[0025] The number of copper strips in the connection unit is two (the width of each copper strip is 0.5mm), and the two copper strips extend from the two sides of the edge of one of the process sides to the other process side along the straight line where the process side is located, so that Connect two process edg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap