Subcircular back-off heliostat

A heliostat and inverted buckle technology, which is applied in the field of heliostat devices for tower-type solar thermal power plants, can solve the problems of increasing heliostat maintenance costs, increasing the cleaning frequency of reflectors, and reducing the concentrating efficiency of mirror fields, etc. , to achieve the effect of shortening the debugging cycle, reducing the cleaning frequency and improving the efficiency of the mirror field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1 of the present invention is a U-shaped column symmetrically supported near-circular heliostat.

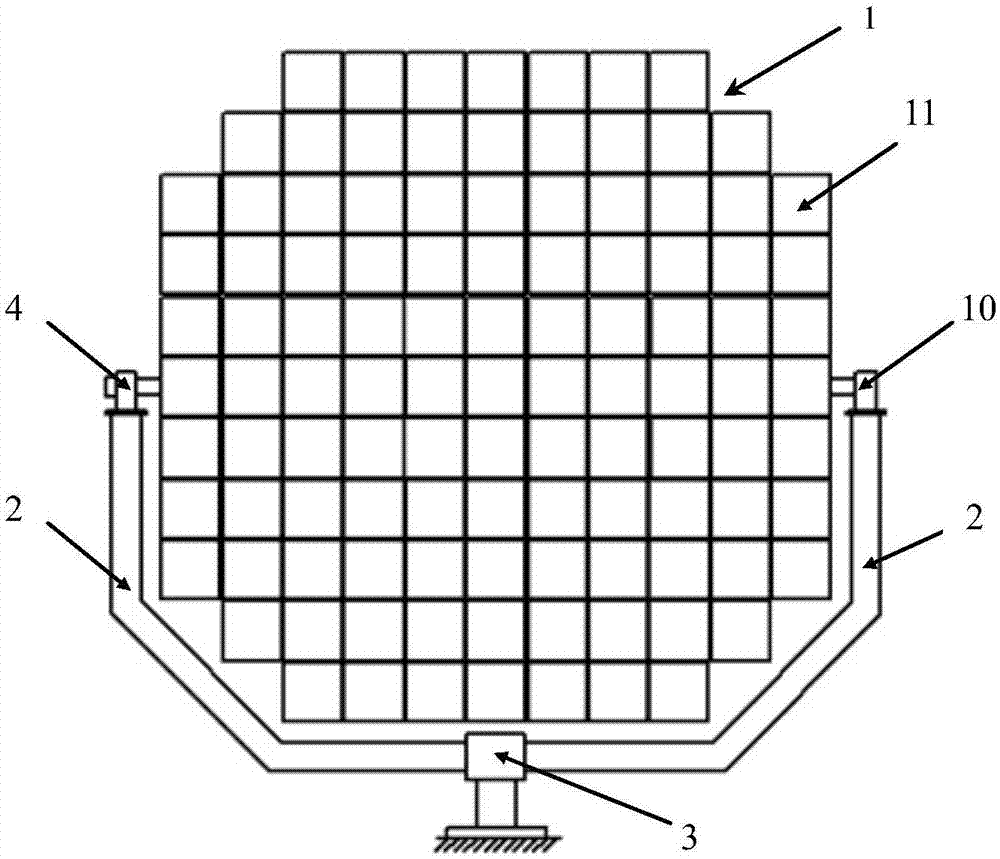

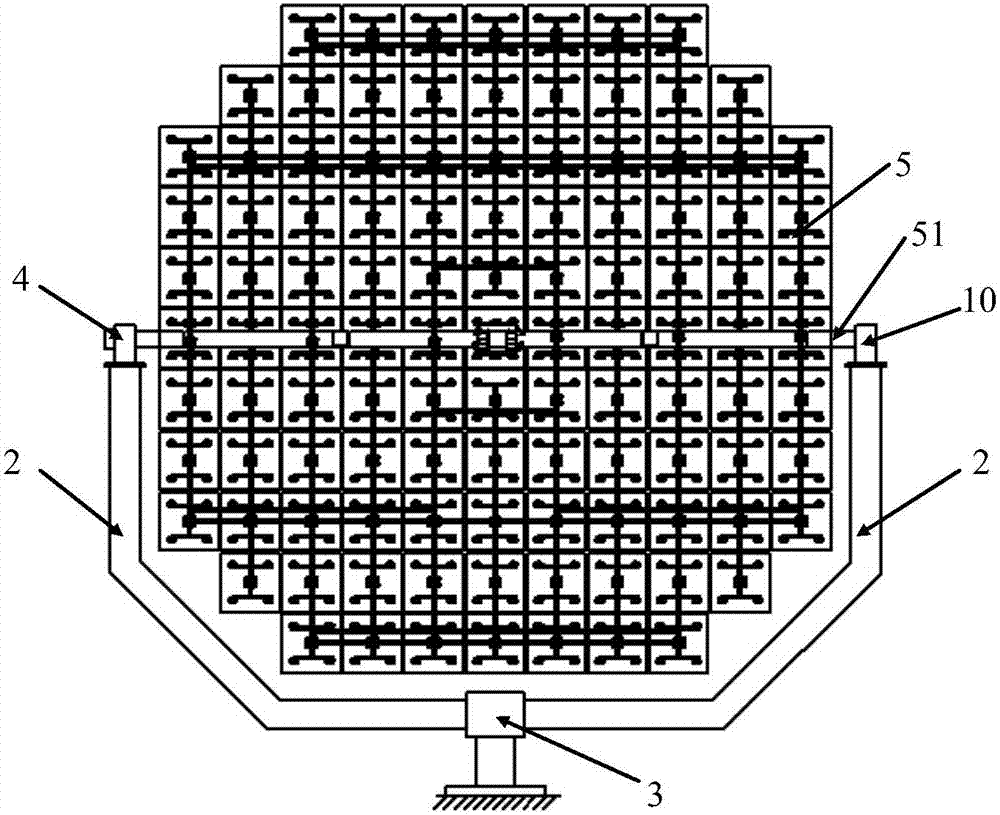

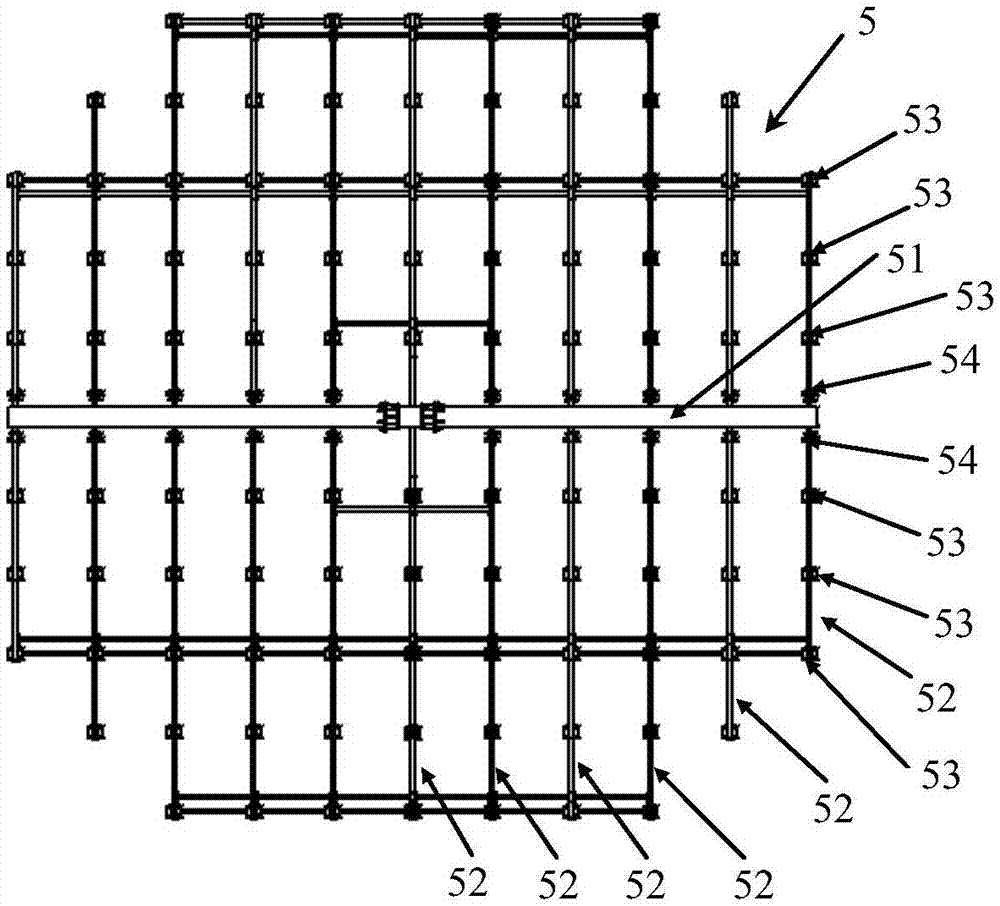

[0019] Overall structure of the present invention is as figure 1 and figure 2 shown. figure 1 is the front view of the structural diagram of the heliostat, figure 2 A rear view of the structure. The heliostat includes a reflector 1 , a U-shaped column 2 , an azimuth transmission device 3 , an elevation angle transmission device 4 and a mirror support 5 . The reflector 1 is formed by splicing several reflector units 11 in a linear array or a circular array, and the profile shape of the spliced reflector 1 is circular or nearly circular, that is, no reflector units are arranged at the four corners of the reflector 1 . When several rows of heliostats constitute a heliostat field, the sunlight blocking and shadowing phenomenon can be reduced between the adjacent front and back rows of heliostats, the row spacing of heliostats can be reduced, and the concentr...

Embodiment 2

[0022] Embodiment 2 of the present invention is a three-point symmetrical support type heliostat, such as Figure 4 shown. When the size of the heliostat is large and the span in the horizontal direction is large, a three-point symmetrically supported heliostat can be used. That is, a central column 21 is added in the middle of the U-shaped column 2, and the axis of the central column 21 coincides with the output axis of the azimuth transmission device 3, which is the azimuth rotation axis. The height angle transmission device 4 is fixed on the top of the central column 21. The height angle transmission device 4 is a horizontal double output shaft, and the horizontal double output axis is the height angle rotation axis of the heliostat. Rotation supports 10 and 20 are used as auxiliary supports, fixed on the tops of both sides of the U-shaped column 2, which can reduce the deformation of the beam 51 and make the reflective surface shape of the reflector 1 controlled within th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com