Quantum dot film with wide color gamut and preparation method thereof

A quantum dot film and technology of quantum dots, which are applied in the field of quantum dot film with wide color gamut and its preparation, can solve problems such as it is difficult to achieve 100% NTSC, and achieve the effects of high uniformity, uniform distribution and good optical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The preparation method of the quantum dot film that the present invention also provides comprises the following steps:

[0061] (1) preparing an inorganic barrier layer by chemical vapor deposition on the upper surface of the organic barrier layer;

[0062] (2) preparing a protective layer on the lower surface of the organic barrier layer to obtain a pre-composite layer comprising a protective layer and a barrier layer;

[0063] (3) using a structural roller to coat a quantum dot layer with a prism structure on the surface of the inorganic barrier film of the pre-composite layer;

[0064] (4) coating the second quantum dot layer on the quantum dot layer of the prism structure;

[0065] (5) on the surface of the second quantum dot layer, cover a pre-composite layer, so that the surface of the inorganic barrier layer of the pre-compound layer is connected with the surface of the second quantum dot layer;

[0066] (6) By curing, a quantum dot film is obtained.

[0067] ...

Embodiment 1

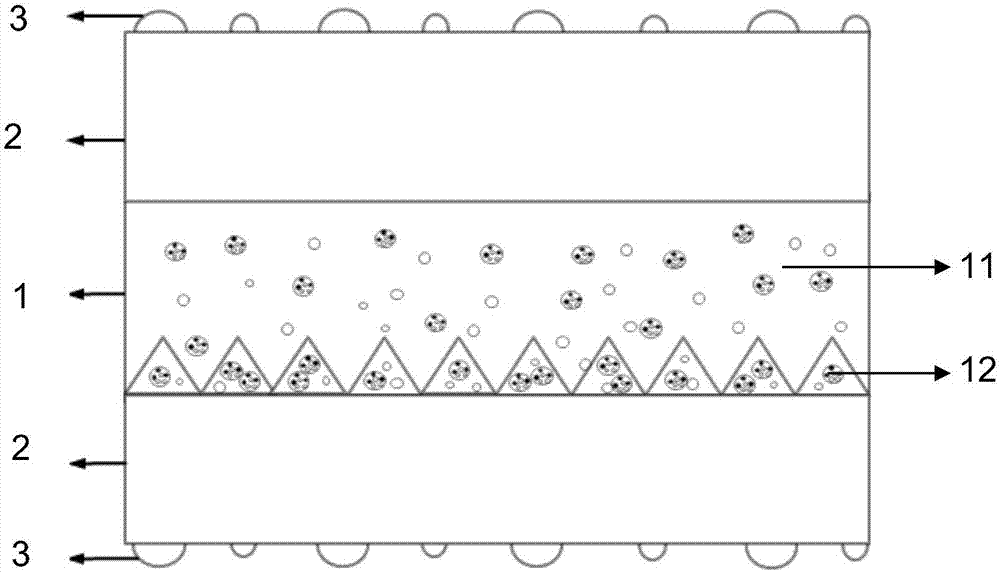

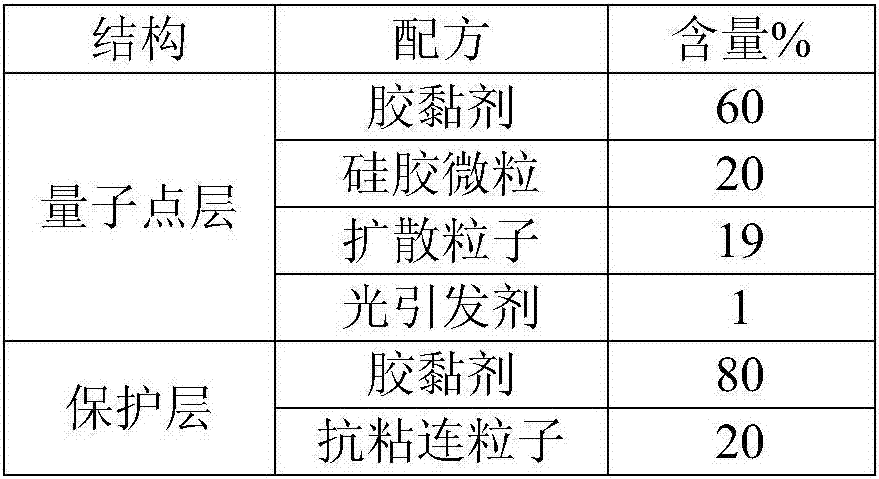

[0071] The quantum dot film provided by the invention has a symmetrical structure up and down, including a quantum dot layer, upper and lower barrier layers and upper and lower protective layers. The formulations of quantum dot layer and protective layer are shown in Table 1. The thickness of each layer is shown in Table 2. The adhesive of the quantum dot layer is polyester acrylate, the diffusion particles are polymethyl methacrylate particles and silicon dioxide particles, the mass ratio of the two is 6:1, and the particle size of the diffusion particles is 1-15 μm; silica gel particles The particle diameter of the silica gel particle is 10-20 μm, and the pore diameter of the micropore on the silica gel particle is 5-20 nm; the quantum dot particle accounts for 5% of the weight of the silica gel particle; and the photoinitiator adopts methyl o-benzoylbenzoate. The prism apex angle of the quantum dot layer of the prism structure is 90°, and the base of the triangle in the cr...

Embodiment 2

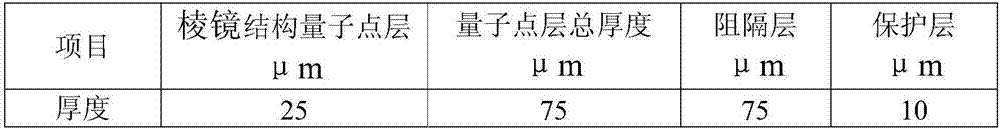

[0077] For the quantum dot film provided in Example 1, the formulations of the quantum dot layer and the protective layer are shown in Table 3. The thickness of each layer is shown in Table 4. The base of the triangle in the cross section of the prism is 75 μm. Quantum dot particles account for 15% of the weight of silica gel particles. The relevant performance test results of the obtained quantum dot film are shown in Table 11.

[0078] The formula of quantum dot layer and protective layer of table 3 embodiment 2

[0079]

[0080] The monolayer thickness of each layer of table 4 embodiment 1

[0081]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com