Miniature no-decanter SBR integrated sewage processing system

A sewage treatment system without decanting technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, biological treatment devices, etc., can solve the problems of short life of blower, difficult sealing of decanter, and high SS of effluent. Achieve the effect of small footprint, low construction cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

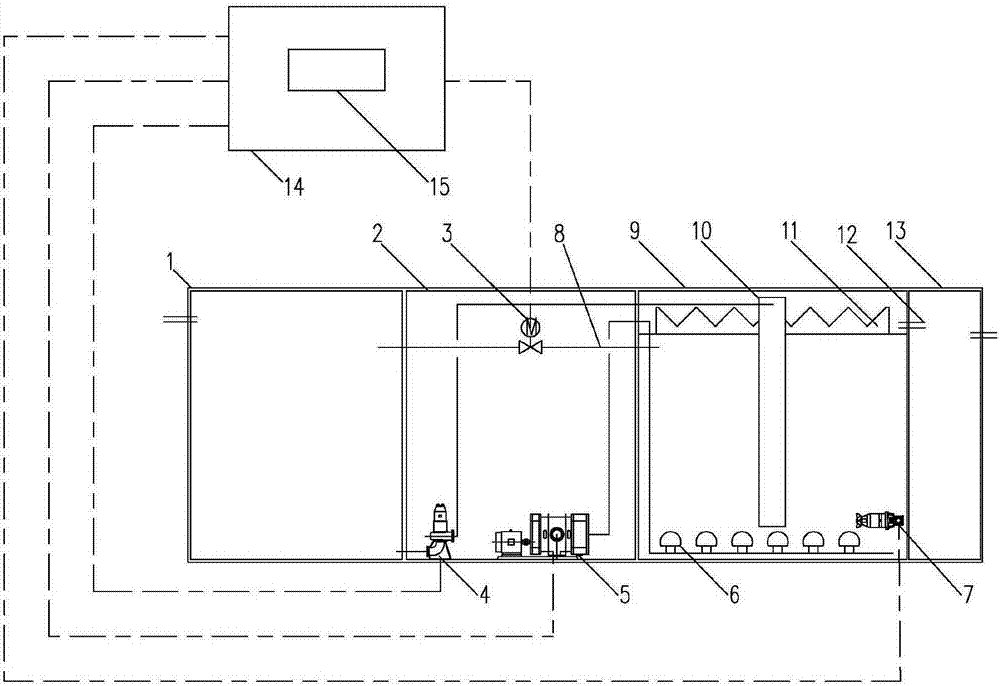

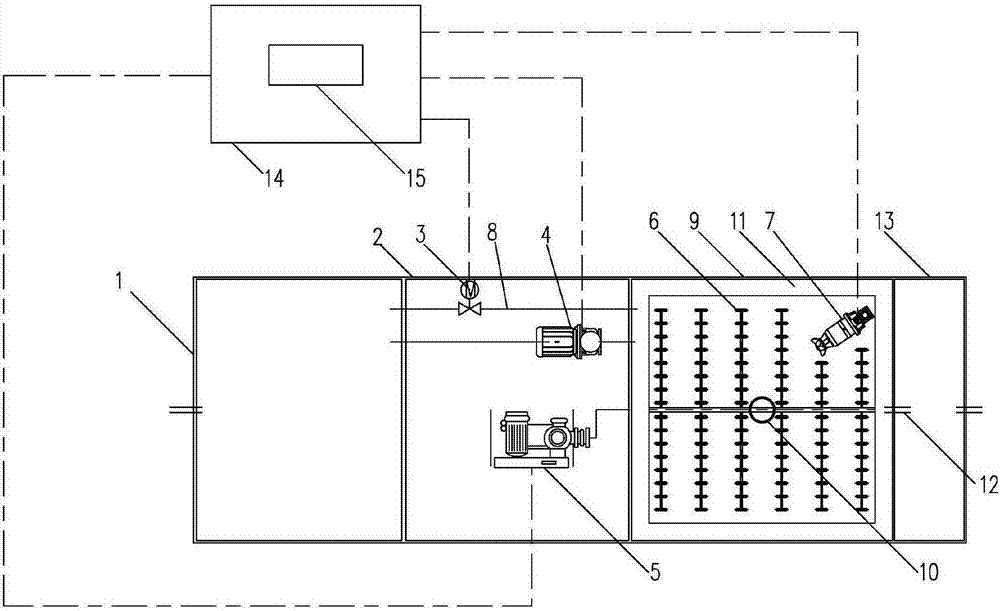

[0025] Such as figure 1 As shown, the present embodiment provides a small-scale non-decanter SBR integrated sewage treatment system, including a control device and a regulating pool 1, an equipment room 2, an SBR reaction pool 9 and a clear water pool 13 arranged in sequence; the equipment room 2 A sewage lifting pump 4 and an aeration device are arranged inside, the inlet of the sewage lifting pump 4 communicates with the bottom of the regulating tank 1, and the outlet of the sewage lifting pump 4 communicates with the upper part of the SBR reaction tank 9; the aeration The air device communicates with the bottom of the SBR reaction tank 9; the SBR reaction tank 9 is provided with a central water distributor 10, and the central water distributor 10 communicates with the water outlet of the lift pump and the central water distributor 10. The water outlet is located at the bottom of the SBR reaction pool 9; a downwater pipe 8 is arranged between the regulating pool 1 and the SB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com