Preparation and applications of heterogeneous catalyst containing MCM-41 mesoporous material

A technology of MCM-41 and catalyst, applied in the field of solid acid catalysis, can solve the problems of high price, low yield, unfavorable promotion and use, etc., and achieve the effects of large specific surface area, easy separation and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Take by weighing 100mg fructose, the Zr-salen-MCM-41 catalyst of 50mg joins in the 25mL reactor that fills 2mLDMSO;

[0033] (2) Replace DMSO in (1) with other solvents, such as NMP, DMA, DMF, THF, DMSO-H 2 O mixture (wherein DMSO and H 2 The volume ratio of O is 1.5:0.5, 1:1, 0.5:1.5), DMSO-[AMIM]Cl (the volume ratio of DMSO to [AMIM]Cl is 1.5:0.5, 1:1, 0.5:1.5) ;

[0034] (3) The above reactor was placed in an oil bath at 140°C and stirred for 4-5 hours. After the reaction was cooled, 50 μL of the reacted solution was diluted to 10 mL with deionized water, and the yield of 5-HMF was determined by HPLC. The results are shown in Table 1.

[0035] Table 1 Solid acid catalyst catalyzes the 5-HMF yield of fructose reaction in different solvents

[0036]

Embodiment 2

[0038] (1) Take by weighing 100mg fructose, the Zr-salen-MCM-41 catalyst of 50mg joins in the 25mL reactor that fills 2mLDMSO;

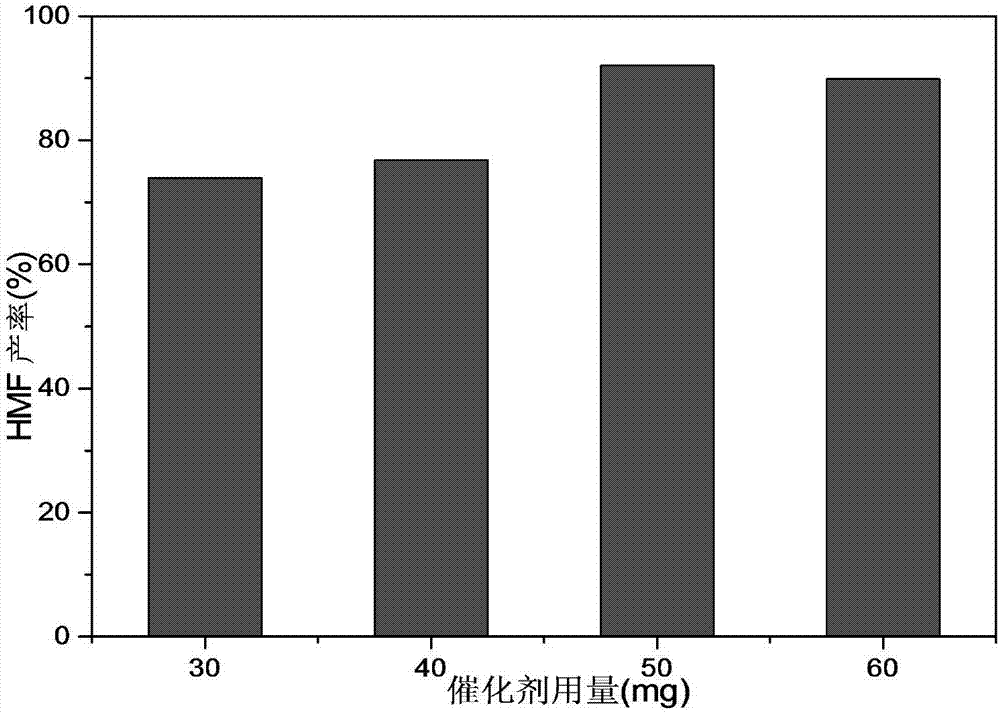

[0039] (2) Replace 50 mg of Zr-salen-MCM-41 in (1) with 30, 40, 60 mg;

[0040] (3) Cool after the above reaction is completed, place the above reactor in an oil bath at 140°C and stir for 4 hours, after the reaction is cooled, take 50 μL of the reacted solution and dilute it to 10 mL with deionized water, and measure the 5-HMF yield by HPLC , the result is as figure 1 shown. The results showed that the yields of 5-HMF obtained by using 30, 40, 50, and 60 mg of catalysts were 74.0%, 76.8%, 92.0%, and 89.9%, respectively.

Embodiment 3

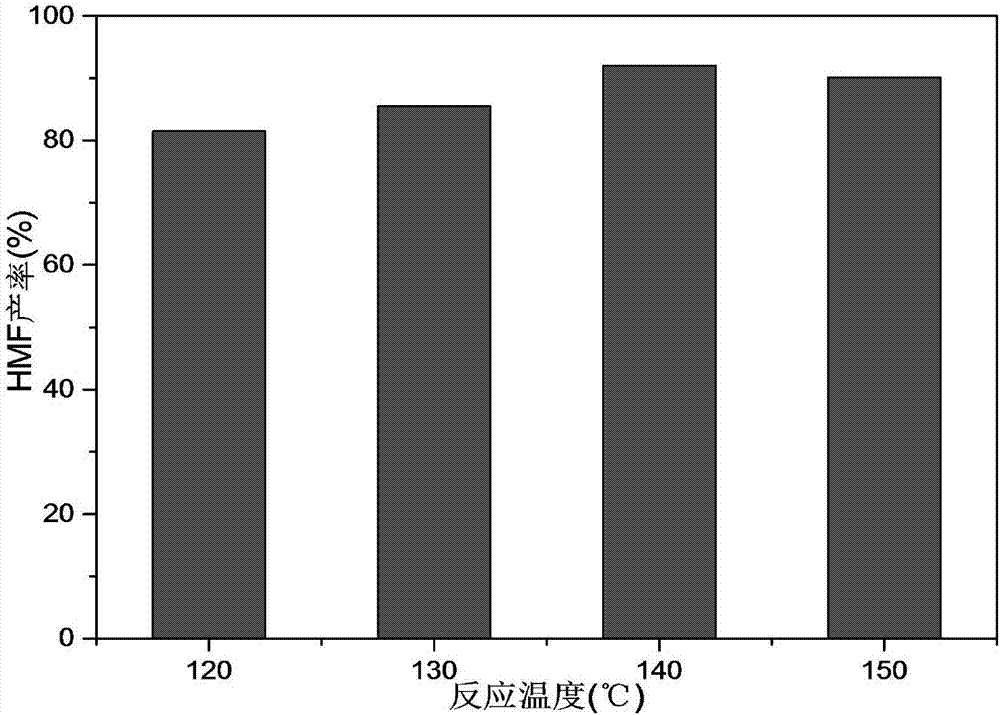

[0042] (1) Weigh 100 mg of fructose, add 50 mg of Zr-salen-MCM-41 catalyst into a 25 mL reactor containing 2 mL of DMSO, place the reactor in an oil bath at 140° C. and stir for 4 h;

[0043] (2) Set the temperature of the oil bath in (1) to 120, 130, 150°C and stir for 4 hours;

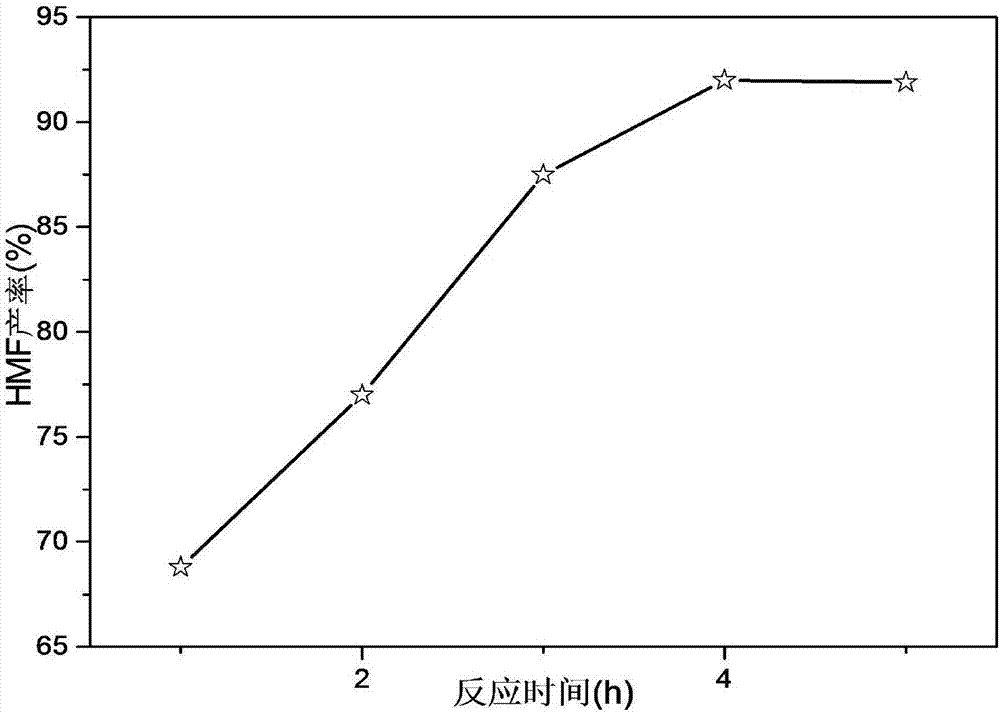

[0044] (3) After the above reaction is completed, cool down, take 50 μL of the reacted solution and dilute it into 10 mL with deionized water, and measure the 5-HMF productive rate with HPLC, the results are as follows figure 2 shown. The results showed that with the increase of time, the yield of HMF gradually increased, and at 140°C, the maximum yield of HMF was 92.0%. °C is the optimum reaction temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com